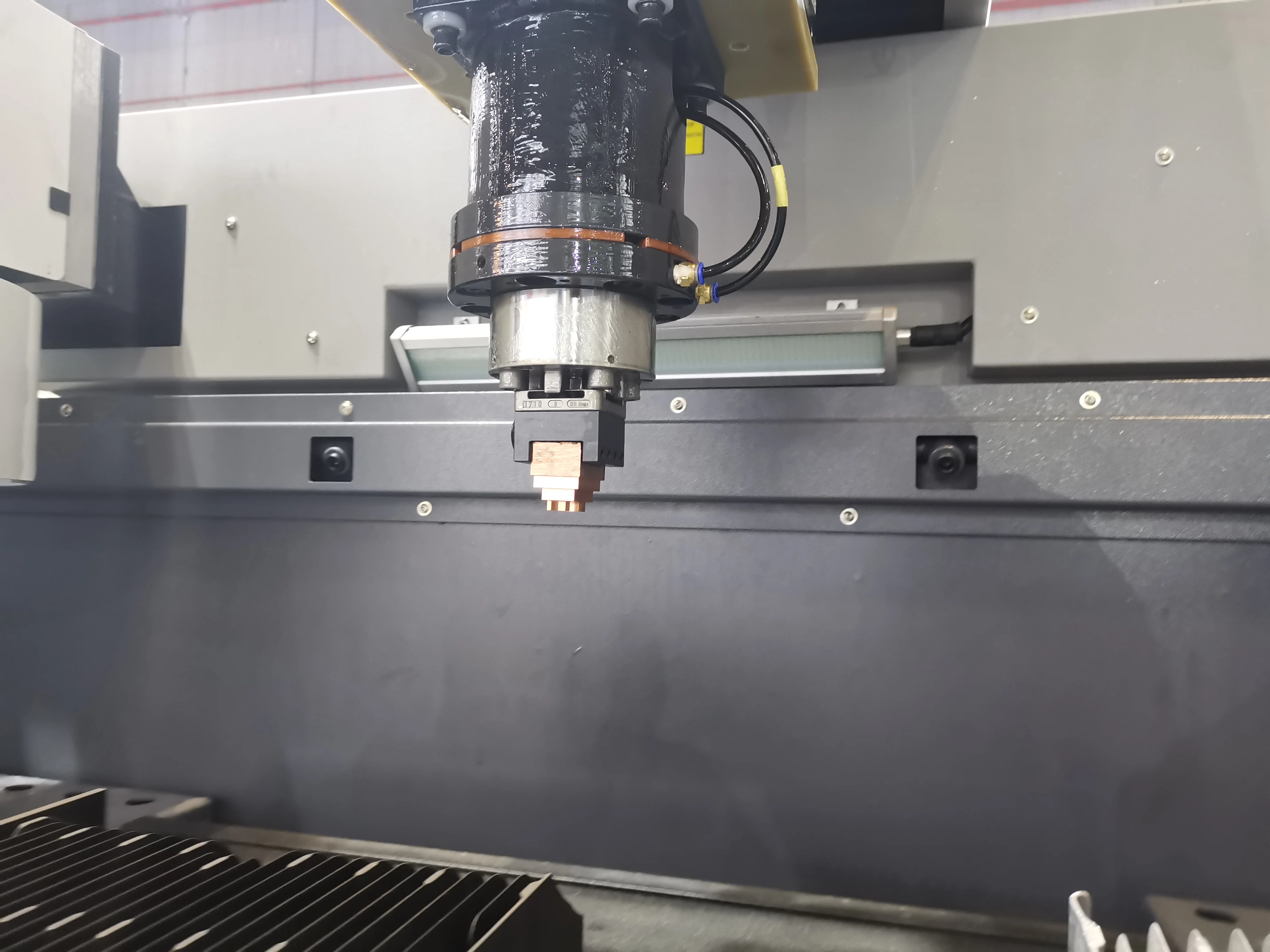

EDM станки CNC машина Sinker Die тонущий станок

- Категория: >>>

- Поставщик: Taizhou Taisen Electromechanical Co. Ltd.

Сохранить в закладки 1600251346069:

Описание и отзывы

Характеристики

Advantages of DMNC A540:

1.5th generation EDM machining control system

2.Smart expert database.

3.Excellent performance of both cooper and graphite electrode machining.

4.Min machining current 0.1A.

5.Best surface finish Ra≤0.2µm.

6.Min. wear of electrode ≤0.1%

7.2 years aging treatment of casting of machine.

8.Ram type structure, fixed working table, heavy load capacity

9.Obtained national design patent of rotary panel cabinet.

10.Man-machine engineering friendly.

11.Optimized high frequency power control system.

12.Most efficient control circuits.

13.Machine body had been analyzed by finite element analysis.

14.High quality casting with enhanced structural ribs.

Specification:

No. | Name | A540 |

1 | Working table dimension(L×W) | 800×500mm |

2 | X×Y×Z axis travel | 500×400×300mm |

3 | Working tank dimension(L×W×H) | 1400×900×500mm |

4 | Highest level of working liquid | 360mm |

5 | End of spindle to working table | 400-700mm |

6 | Capacity of oil tank | 940L |

7 | Max weight of electrode | 80kg |

8 | Max weight of workpiece | 1500kg |

9 | Positioning accuracy | 5µm |

10 | Repeat positioning accuracy | 3µm |

11 | Weight of machine | 3300kg |

12 | Dimension of machine | 2525×2755×2526mm |

13 | General input | 9kVA(50A) |

14 | Input power | 3 Phase 380/50Hz |

15 | CNC power generator | A3-50 |

16 | Max working current | 50A |

17 | Best surface finish | Ra≤0.2µm |

18 | Min. wear of electrode | ≤0.05% |

19 | Max machining efficiency | ≥500mm3/min |

20 | Interpolation methods | Straight line, arc, helix |

21 | Accuracy compensation options | Step pitch compensation of each axis, gap compensation |

22 | Min. drive unit, Min command unit | 1µm |

23 | Outer dimension of controller | 1250×550×1800mm |

24 | Display | 15 inch touch screen |

25 | Remote control | different gradesMFR0-3 |

Functions of Controller:

No. | Function explanation |

1 | LCD, touch screen input |

2 | Simultaneous three axis control(optional 4-axis simultaneous control) |

3 | Super finish PIKA machining circuits-mirror surface machining function; excellent performance of corner clearing |

4 | Expert machining parameters database: with high explosive power circuit, specially good for processing hard alloy material) Automatic and manual machining according to different combination of different material of electrode and workpiece: copper/steel, graphite 1/steel, graphite 2/steel, silver-tungsten/steel, copper-tungsten/steel, silver-tungsten/hard alloy, copper/zinc alloy, graphite/zinc alloy, copper/copper alloy. |

5 | AUTO machining function: Input material of electrode and workpiece, machining area, shrinkage of electrode, required surface finish and etc Then control system automatically calculate machining parameters from rough machining to finish machining according to expert database. |

6 |

End face positioning, cylinder center positioning, corner positioning, inner hole positioning, random three points positioning, discharging position self-decided positioning and etc. |

7 | Utilize automatic positioning function to do online measuring and amending to machined workpiece. |

8 | Real-time monitoring on the discharging status, if any tiny short circuit or arcing happens, system would remove arcing and give alarm |

Parts Made by DMNC EDM Machine:

Professional Factory:

Похожие товары

Газетный Скрап из смешанной бумаги

Densen индивидуальные молотковая мельница дробилка запасные части высоко износостойкие каменные дробилки молотки для дробления известняка

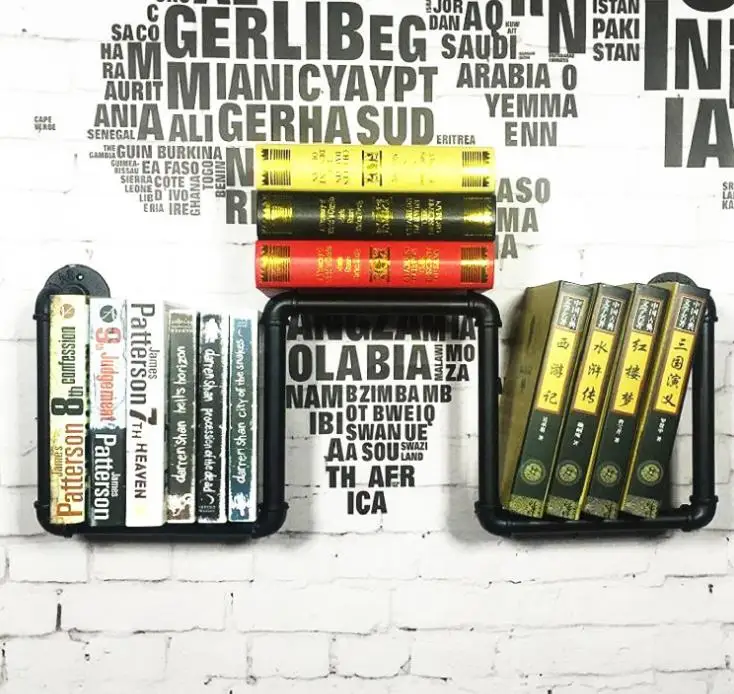

Книжная полка DSDST в стиле стимпанк «сделай сам», черная трубка, промышленная винтажная полка для труб, настенная книжная полка

Китайский завод, 3-индолепропионовая кислота (IPA) CAS 830-96-6 высокого качества

Хорошее качество, Комплект постельного белья из полиэстера и микрофибры на заказ

Набор для плазменной резки/алюминиевый козловой станок с ЧПУ для плазменной резки листового металла

Художественный маркер, чехол для переноски, органайзер для помады-60 отделений, холст или ткань Оксфорд, маркеры на молнии, сумки для хранения

Новые поступления

Новинки товаров от производителей по оптовым ценам