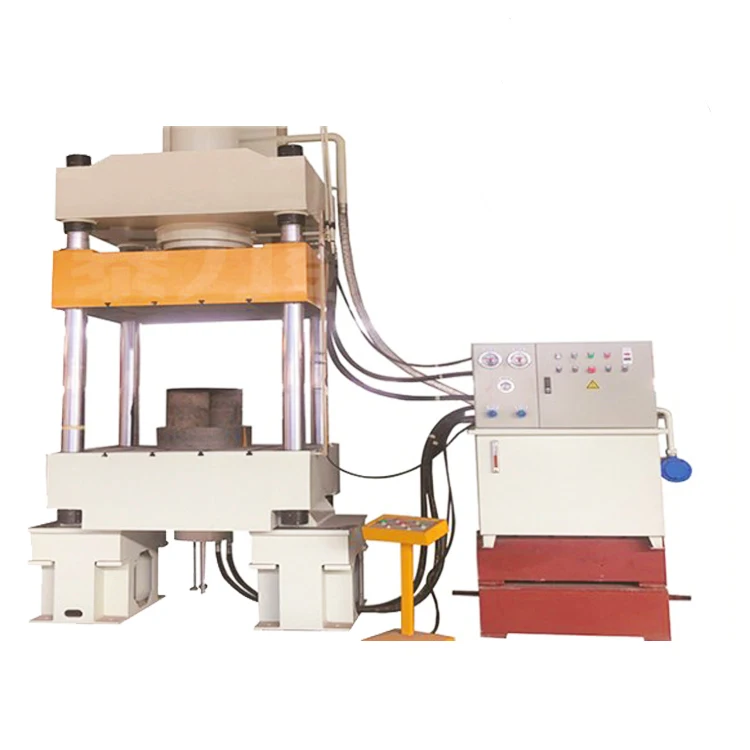

Гидравлическая пресс машина для посуды столовых приборов 200 300 500 тонн

- Категория: Hydraulic Press >>>

- Поставщик: Jieyang Jiedong Quxi Jingcheng Machinery Factory

Сохранить в закладки 1600253678164:

Описание и отзывы

Характеристики

H Frame Hydraulic Press Machine

Best inquiry with follow information:

1. Photo of the sample.

2. What's material.

3. Minimum and maximum length, weight and thickness of sample.

4. Production capacity and situation of your factory.

The frame of the hydraulic press is fully welded, after manual aging and polishing rust-proof treatment. Production efficiency is high with the fast-falling speed of the moving sliding bolster.

| Model | YDK-100 | YDK-200 | YDK-300 | YDK-500 | ||

| Main cylinder | Nominal force | KN | 1000 | 2000 | 3000 | 6000 |

| Maximum stroke | mm | 160 | 160 | 160 | 160 | |

| Open height | mm | 360 | 360 | 370 | 450 | |

| Fix table height from the ground | mm | 650 | 650 | 650 | 950 | |

| Activities under the table fast speed | mm | 280 | 260 | 250 | 250 | |

| Return activity table speed | mm/s | 250 | 240 | 230 | 210 | |

| Machine dimensions | L-R | mm | 1000 | 1100 | 1200 | 1600 |

| F-B | mm | 900 | 1050 | 1150 | 1200 | |

| H | mm | 1850 | 1870 | 1880 | 2250 | |

| Moter power | KW | 7.5 | 7.5 | 11 | 18.5 | |

Pressure, stroke, and pressure time can be adjusted according to processing requirements. There are a large workbench and mold filling space. High precision, eight side slide rail orientation. The operation is safer and the lubrication system is continuously cooled repeatedly by fixed point and quantitative dilute the oil.

| Piston Rod

The surface hardness of the piston rod reaches 55°C, which effectively solves the damage of the seal ring and is not easy to scratch. |

Electrical Appliances

The electrical appliances use Mitsubishi PLC, it realizes electro-hydraulic control, jogging, manual and semi-automatic operation modes together with hydraulic valves. |  |

| Oil Pump

The oil pump to reduce the heat generated when the oil is pumped out. Extending the service life of the machine |

This hydraulic machine can be cooperated with automatic feeding machine. It is with the advanced technology on the embossing/bending/stamping/forming the metal material products, not only the SUS cutlery items, but also ranges of spare parts. With the Sensor of machine for safe working, humanity design makes the job easier.

JEC Cutlery Equipment Co., Ltd. focuses on providing customers with one shop of machinery and equipment for cutlery and tableware production line. One of the core businesses is the manufacturing and development of automatically cutlery machinery production lines. JEC main items are our hydraulic press, horizontal press, automatically feeding machine, polishing solution, mold, saving customers’ time and cost by automating as much as possible. With more than 10 years of oversea market experience, we wholeheartedly provide customers with advanced technology and efficient production lines to improve their market competitiveness.

We have engineers’ team who has worked in this industry for more than 15 years. With professional knowledge, we can provide most suitable suggestions and solutions for the entire cutlery/tableware production line. Rich installation experience at home and abroad.

Q: How to select the right machine for your project?

A: Please just help send the below information, our engineers will help make the best solution for you. 1. Items information: photo, material, size, thickness 2, capacity equipment and how automatically do you need. Where is your location? We are in jieyang city, which is very famous on the sus material and cutlery making. Air port name is: chaoshan air port. High speed train station: chaoshan station.

Q: Are you factory or not?

A: We are factory specializing on cutlery making machine making for over 13years, but also help clients purchase some related machine or material for cutlery/tableware items.

Q: If I want to set up a factory, could you help?

A: Yes, our engineers will help you analysis on the samples situation, your capacity request and your project plan then we will help give the best suggestion on layout, design, quotation.

Q: Trade terms?

A: EXW or CIF, FOB are acceptable.

Q: Terms of payment?

A: 30% T/T deposit, 70% balance payment before shipment.

Q: Delivery time?

A: 15~60 days depend on the orders.

Q: Warranty?

A: One year of guarantee except the easy - damaged parts and engineers will provide the online technical supports all the time.

Похожие товары

Гидравлическая керамическая машина для прессования порошка циркония

Полностью автоматическая гидравлическая пресс-формовочная машина

Yongheng гидравлический 1200 тонн четырехколонный гидравлический пресс машина для формовки воды гидравлический пресс цена

Yongheng гидравлический Y98-600 промышленное высокое производство Servo c металлическими нержавеющая стальная труба гидроформинг машина тройник пресс

Y32-100Ton 4 гидравлический пресс для глубокого вытягивания

Гидравлический пресс 315 тонны для крышки люка

Деревообрабатывающая фанера полный набор оборудования холодный пресс Масляный Пресс гидравлическая многослойная доска

Новые поступления

Новинки товаров от производителей по оптовым ценам