IC подключаемый станок от производителя автономный горизонтальный элемент резисторный диод

- Категория: Electronics Production Machinery >>>

- Поставщик: Guangzhou Minder-Hightech Co. Ltd.

Сохранить в закладки 1600255593844:

Описание и отзывы

Характеристики

Product Description

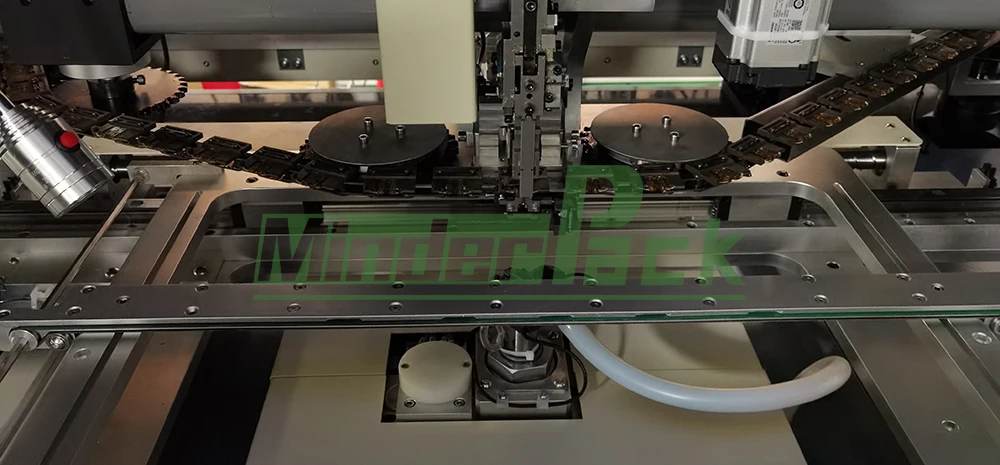

Shaped horizontal insertion(plug in) machine

Non-standard braided horizontal component plug-in machine automatically inserts various non-standard braided horizontal components into the PCB according to the set program. It has the fixed tail function and the detection function to achieve high speed, high precision and high stable insertion effect

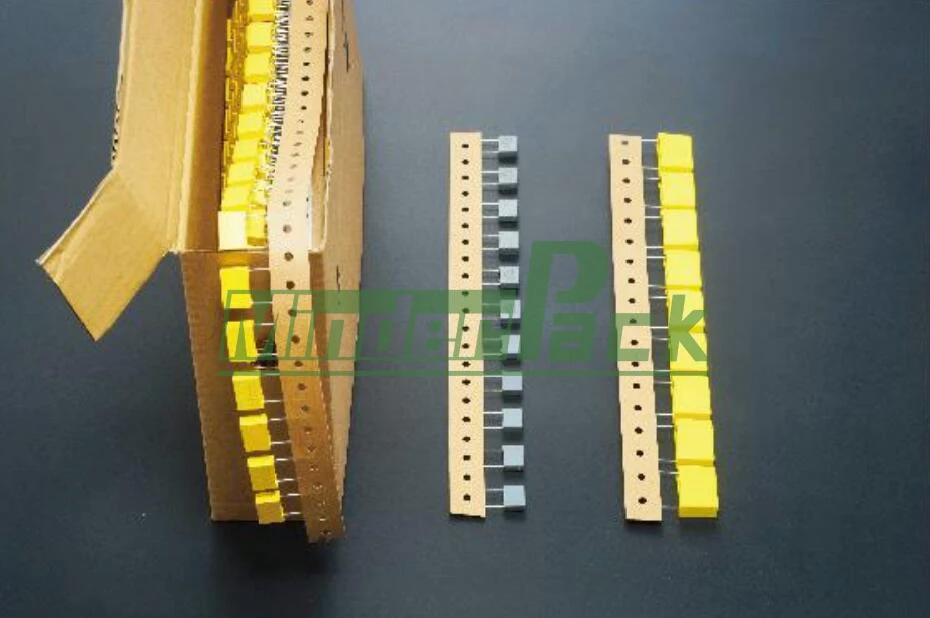

Some of plug-in parts:

Specification

Components | Connector: 40*13*26mm (maximum) | Feeding system | Vibrating plate, feeder |

Plugin speed | 0.45s/Piece | Motion accuracy | 0.001/pulse |

Loading and unloading PCB time | 3s | Motion system | Panasonic servo controller, motor |

Component packaging | Bulk | Programming function | Online visual programming Visual correction Easy EXCEL process |

Loadable PCB size | Maximum 380*280mm; Minimum 50*50mm (Customizable) | Data input | USB interface import Manual entry |

Number of plug-in header | 1-6, can be used for connectors of different specifications. | communication interface | RS232C |

Component requirements | PIN foot diameter 0.4-1.2mm | Power supply | 220V/AC 50/60Hz,2KVA |

PCB board requirements | Positioning hole The aperture is larger than the end of the component. | Air pressure | 5-6kg/cm2 |

Insertion mode | set at 0,±90 degrees | Noise | ≤75db |

Distance between components | 2mm | Ambient temperature | 10℃-30℃ |

Component direction detection | Vibrating plate detects material | Ambient humidity | 30%-70% |

Component fixing method | Inward bending of two feet with detection function | Air consumption | 0.63m3/min |

Control System | Independent research and development control system Industrial computer + motion control | Dimension | 1950*1200*1530mm |

Display system | 17-inch color LCD | Weight | 1500kg |

Product configuration:

Operation system:

Operating software, production data, management data, equipment parameters, editing programs, all I/O signal diagnosis, etc. running under Windows environment can be completed on the host. The interface is humanized, and the application of high-tech technology makes the equipment introduction efficient and easy to use. ,easy to use

Visual System:

The industrial-specific high-definition camera and the self-developed vision correction software form a vision system. The

deviation between the PCB hole position and the programmed input coordinates can be quickly and automatically calibrated to match all the coordinates with the actual PCB hole position, ensuring the plug-in accuracy and greatly improving the programming efficiency.

deviation between the PCB hole position and the programmed input coordinates can be quickly and automatically calibrated to match all the coordinates with the actual PCB hole position, ensuring the plug-in accuracy and greatly improving the programming efficiency.

Plug in speed:

0.8 seconds / piece, equipped with Panasonic AC servo drive, high speed, low noise, smooth motion

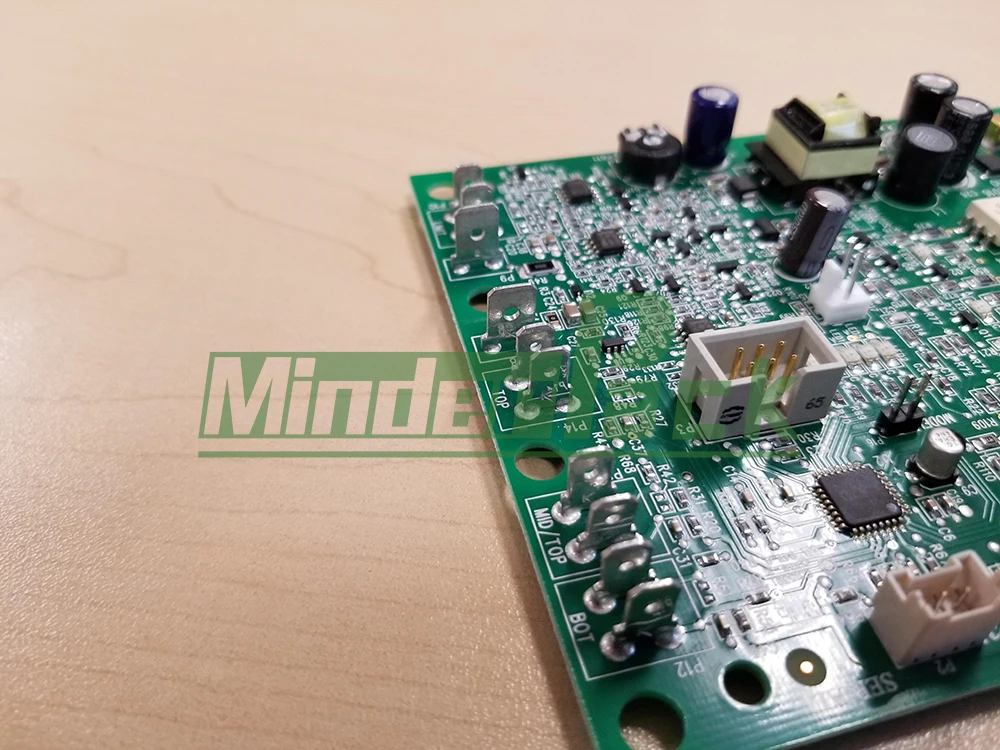

Sample

Why Choose Us

Provide professional process solutions according to customer product characteristics;

Professional engineers provide 7*24-hour online services to provide customers with one-to-one professional training to ensure that customers worry-free use;

Original accessories, professional CNC machining center, perfect quality control, durable products.

Professional engineers provide 7*24-hour online services to provide customers with one-to-one professional training to ensure that customers worry-free use;

Original accessories, professional CNC machining center, perfect quality control, durable products.

Company Profile

Our Factory

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Похожие товары

Трафаретный принтер QH3040, монтируемый чип TVM802A, духовой шкаф QR5040D, производственная линия светодиодов

Juki швейная машина SMT JUKI JX-350 захвата и установки машины

SMT машина Фидер загрузка зажим SAMSUNG SM

Скребок для паяльной пасты SMT GH

Части машины SMT KE1710 драйвер Y HM001820010 модель MR-J2S-70A

QIHE smt машина для сборки, 64 кормушки, автоматическая smt машина для сборки и установки, smt Монтажная линия

6 899,00 $ - 6 999,00 $

Оригинальный вентилятор охлаждения сварочного аппарата серии Fanuc 9WF0624H4D03

382,56 ₽ - 1 530,21 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

Умный цифровой электронный ручной инфракрасный лазерный термометр для ветеринарного и медицинского мониторинга человека

5-10 $

Цифровой инфракрасный лазерный термометр для взрослых

5,90-6,70 $

Командная версия 24-скоростной ультралегкий карбоновый шоссейный велосипед Гоночная рама и комплект колес

Четырехцилиндровый двигатель CA6110/125G5 части клапана 1007011-A013-0000 1007016-A013-0000

0,50 $

55203781 46740344 55181201 55266538 зубчатый шкив коленчатого вала для FIAT 500 BRAVA BRAVO DOBLO PANDA PUNT0

3-3,70 $

Оптовая продажа 100% Рафинированное Масло из семян подсолнечника малазия масло для приготовления пищи

GY031 металлическая рамка пользовательских игровых сидений Sim гоночные игровые сиденья симулятор вождения кабины для Xbox 360 Logitech G25 G27 G29 G920

88-143 $

Роскошные пользовательские островные стулья современные кухонные с выдвижными ящиками и раковиной кухонный шкаф U-образной формы из нержавеющей стали

160-180 $