Вертикальный струйный принтер 3D обои фотообои HD автоматическая машина для покраски без пистолета

- Категория: >>>

- Поставщик: Shenzhen Lingchen Technology Intelligence Co. Ltd.

Сохранить в закладки 1600256179929:

Описание и отзывы

Характеристики

Product Description

Company Profile

Functions and features

①. The main body of the machine is assembled with profiles made of special formula aluminum-magnesium alloy, with high strength, high structural precision, highly integrated light and thin chassis, light weight and durable, and the overall transportation is convenient;

②. The body parts are all processed and manufactured with imported CNC equipment, coupled with professional mold parts manufacturing technology, to ensure the consistency and higher stability of the whole machine and parts;

③. It has a high-precision brushless servo motor control system, vector positioning, no strip grating, no carbon brush for the motor, (saving cleaning, maintenance, garbled graphics after wear, regular replacement, etc.) to achieve higher painting accuracy , Faster painting speed, and maintenance-free;

④. Using high-definition piezoelectric inkjet technology, Japan imported EPSON Epson (specially made) piezoelectric nozzle, high precision, fast speed and durability;

⑤. Adopting VSDT variable ink drop technology, supporting Aipu's new program algorithm, the minimum ink drop is 3.5PL, the maximum is 27PL, indoor painting, the picture is clear and delicate; outdoor painting, the color is bright, fast, thick ink and heavy color are also available, fresh and elegant, Reflect the perfect painting quality;

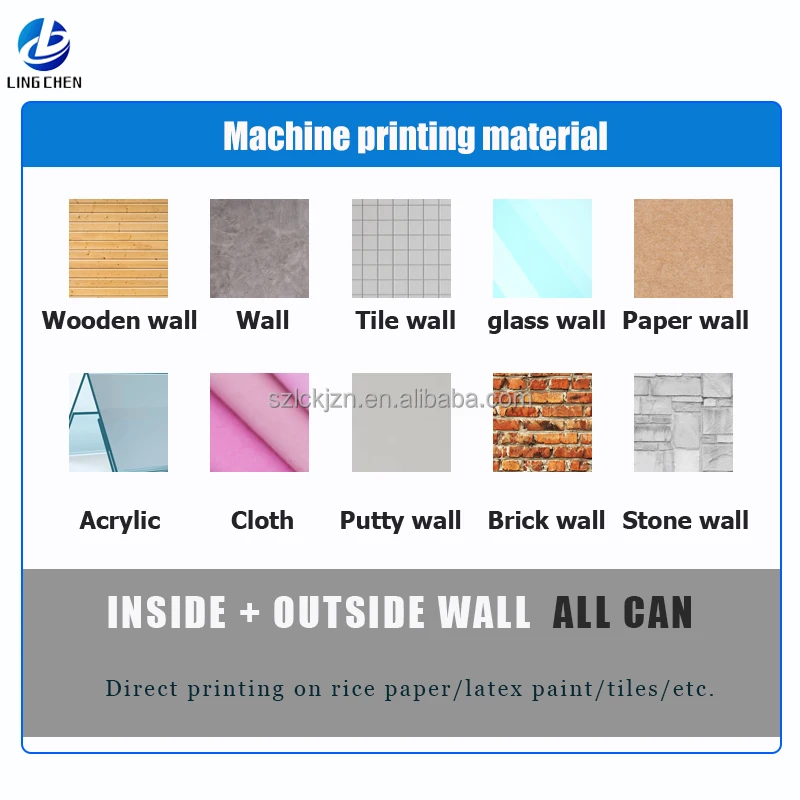

⑥. The combination of advanced ink drop control method and high fault-tolerant feathering technology ensures a more perfect output quality, which can be adapted to painting with more special materials, such as: internal and external putty wall, latex paint wall, large white, imitation porcelain wall , Ceramic tiles, glass, rice paper, canvas, wall clothing, colored glaze, shell powder, colored grain paint and other wall surfaces...;

⑦. Special ink for wall painting, without heating, works normally in an environment of minus 10°C to minus 60°C, without freezing and inking continuously. Bright colors, strong three-dimensional effect; no fading, no peeling, scrub resistance, green environmental protection certification, national standard testing qualified (GB18582-2001, GBT9756-2001);

⑧. The data signal of the print head adopts optical fiber integrated transmission (its advantages are: faster speed, strong anti-interference ability,

High reliability. Transmission data is more stable);

High reliability. Transmission data is more stable);

⑨. The machine is equipped with the most cutting-edge automatic drawing system, which is unexpectedly interrupted during construction. The drawing system can effectively reduce the scrap rate of colored drawings;

⑩. Adopting ALTERA's high-speed USB2.0+ control system, the speed is up to 480M/S, which can stably support the full-speed printing of the nozzle;

⑪. Support WindowsXP, Win7, Win8, Win10 multiple operating systems;

⑫. Independent research and development of CPLD programmable logic control system, after years of use and practice, stable performance, in line with military standards;

⑬. Advanced AC servo control technology ensures higher precision printing, better stability and longer service life;

⑭. The integrated head design and detachable structure can effectively avoid damage caused by bumps during transportation; the full-enclosed nozzle mounting plate can prolong the actual service life of the nozzle;

⑭. The integrated head design and detachable structure can effectively avoid damage caused by bumps during transportation; the full-enclosed nozzle mounting plate can prolong the actual service life of the nozzle;

⑮. Simple multi-color integrated ink cartridge ink supply system, stable and convenient, supports quick pipeline separation, water and electricity separation, take it and put it on the go;

⑯. Adopt American imported Banner sensor system, dual sensors, up and down two-way induction, curved surface tracking, automatic positioning, and automatically solve the problems of uneven walls and inclined walls, effectively reducing the damage rate of the machine head.

⑰.Shenzhen Lingchen Technology Intelligent Co., Ltd.-Wall Printer Function Configuration Introduction

FAQ

1. Can I test the printing effect of some pictures?

Yes, you can provide me with the pictures you need to test, take a video for viewing when printing or mail a printed sample. Or go directly to the site for inspection and printing.

2. Where do I need to purchase subsequent consumables for the machine?

We will continue to provide ink tracking services, the more quantity you order, the cheaper the price.

3. How much is the ink printing cost of this machine?

The cost of inkjet ink per square area is about $0.5.

4. How should I operate this machine?

Provide video manual tutorials, one-to-one remote guidance.

5. If I encounter some technical problems, how can you help me?

Detailed descriptions, photos or videos will help our technicians analyze the problem and provide corresponding solutions.

6. Is the machine stable? What should I do if I need to replace it?

Our printer is very stable. If any part is damaged, we will repair it or send you new parts. After the user sends out the damaged parts, we will provide a set of vulnerable spare parts when purchasing the machine.

7. How long is your warranty period?

Three-year warranty and lifetime maintenance.

8. How long is your delivery time?

The stock can be delivered to the freight forwarder within three days.

9. How to order the machine?

Prepay 30% of the equipment deposit, deliver the equipment to the freight forwarder, and pay the balance.

10. Can we send technicians to your company for training?

Yes, you are welcome to visit anytime, anywhere.

Yes, you can provide me with the pictures you need to test, take a video for viewing when printing or mail a printed sample. Or go directly to the site for inspection and printing.

2. Where do I need to purchase subsequent consumables for the machine?

We will continue to provide ink tracking services, the more quantity you order, the cheaper the price.

3. How much is the ink printing cost of this machine?

The cost of inkjet ink per square area is about $0.5.

4. How should I operate this machine?

Provide video manual tutorials, one-to-one remote guidance.

5. If I encounter some technical problems, how can you help me?

Detailed descriptions, photos or videos will help our technicians analyze the problem and provide corresponding solutions.

6. Is the machine stable? What should I do if I need to replace it?

Our printer is very stable. If any part is damaged, we will repair it or send you new parts. After the user sends out the damaged parts, we will provide a set of vulnerable spare parts when purchasing the machine.

7. How long is your warranty period?

Three-year warranty and lifetime maintenance.

8. How long is your delivery time?

The stock can be delivered to the freight forwarder within three days.

9. How to order the machine?

Prepay 30% of the equipment deposit, deliver the equipment to the freight forwarder, and pay the balance.

10. Can we send technicians to your company for training?

Yes, you are welcome to visit anytime, anywhere.

Похожие товары

Медные свечи зажигания OEM ZFR6FGP свечи зажигания Платиновые Свечи Зажигания

Вращающийся магнитный кабель для зарядки и передачи данных телефона 540 градусов

Пользовательский USB 2,0 90 градусов вверх вниз угол мини штекер открытый конец usb кабель от производителя

0,40 $ - 0,50 $

3 в 1 Магнитный вращающийся телефонный кабель с поворотом на 360 градусов для iPhone Micro USB Type C Быстрая зарядка нейлоновый Плетеный Магнитный зарядный кабель

0,60 $ - 0,83 $

Lizone 48 Pin автомобильные ECU корпус провода к доска PCB алюминия корпус ЭБУ Коробка Чехол блока управления двигателем PCM HD-48HAJ LPG/CNG Комплект корпус

Портативный цветной ультразвуковой гинекологический/Ветеринарный ультразвуковой аппарат для беременных

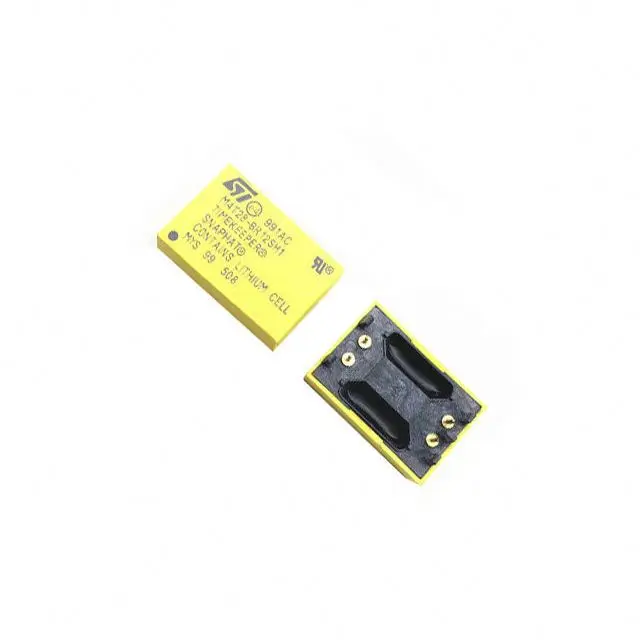

M4t28-Br12sh M4t28 серии 2,8 V 48 мА/ч, монтируемая поверхность, секундомер, Snaphat - Soic-28 микросхема M4t28-Br12sh1

Новые поступления

Новинки товаров от производителей по оптовым ценам

Hantek щупы осциллографа автоматический Тестовый Кабель Ht30a Bnc к банану двойная Банановая головка многоцелевое автомобильное

3,10-3,44 $

Горячая распродажа ручная работа традиционная деревянная урна для домашних животных квадратная коробка золы собак и кошек персонализированная Лучшая цена

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $

Irdmco экологически чистый минималистичный прямоугольный деревянный ящик для хранения стеллаж поделок и детских игрушек Домашняя мебель гостиной

Технология сенсорных перчаток и аксессуары для детей от дождя холода M725132-334

1,07-1,40 $

GY6 6 Pin AC гоночный CDI для CG125 CG250 двигателя Dirt Pit Bike ATV Quad

Парик из синтетического волокна для косплея

9,85-12,66 $

Прямая Продажа с фабрики 65 см Модернизированный подвесный стерео голографический проектор светодиодный вентилятор высокой четкости экран 3D дисплей

155-185 $