Устойчивая толерантность 3d печатная нить ПЭТ экстрадурующая машина Одношнековый экструдер пластиковый Экструдер Производитель

- Категория: >>>

- Поставщик: Dongguan Songhu Plastic Machinery Corp.

Сохранить в закладки 1600274961446:

Описание и отзывы

Характеристики

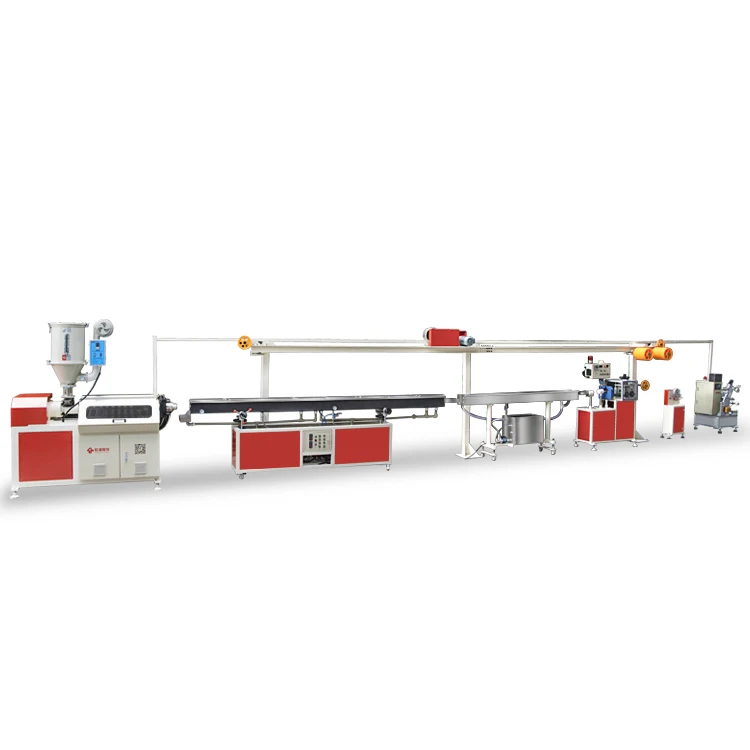

Stable tolerance 3d printing filament PET extrduing machine single screw extruder plastic extrude machine manufacturer

1. Producing process

1)Before starting the producing line,we will dry ABS/PLA/PET for enough time(usually it is 40minutes-1hour).

2)Mix with colors masterbatch or color powders.

3)Adjust temperature and dragging rate,which will guarantee the filament fiameter range at 1.6-1.8mm/2.8-3.0mm,roundness+/-0.05mm,each spool weight 1kg+/-0.0

2.The main part of 3D printer filament plastic extrude machine

| No. | Part name | Quantity | Specifications |

| 1 | SHSH-45 Main Extruder machine | 1set | 45mm screw |

| 2 | High precise extrusion mould(1.75mm/3.0mm) | 1set | Extrusion die is S136 |

| 3 | 4 Meter Automatic Circulation Heating Tank | 1set | SS304 |

| 4 | 2 Meters Cooling Water Tank | 1set | SS304 |

| 5 | independent drying device | 2set | special water sleeve ring |

| 6 | 8 meters Storage device | 1set | tension control |

| 7 | Laser LST-25X | 1set | tolerance +/-0.02mm |

| 8 | Four wheels Haul-off machine | 1set | precision guide pillar |

| 9 | Single station winding machine | 1set | Automatic metering,neaty winding |

1. SHSJ-45MM Main Extruder

-----Model: Φ45

-----Screw (Special for ABS PLA etc. material):

-----Dia: 45mm

----Material: 38CrMoAlA

----Controlling system

----Power: 11KW

----Controlling type: Frequency inverter(Delta)

----Heating control zone: 6

----Barrel air cooling zone: 4

---Mould, a connecting body: 2

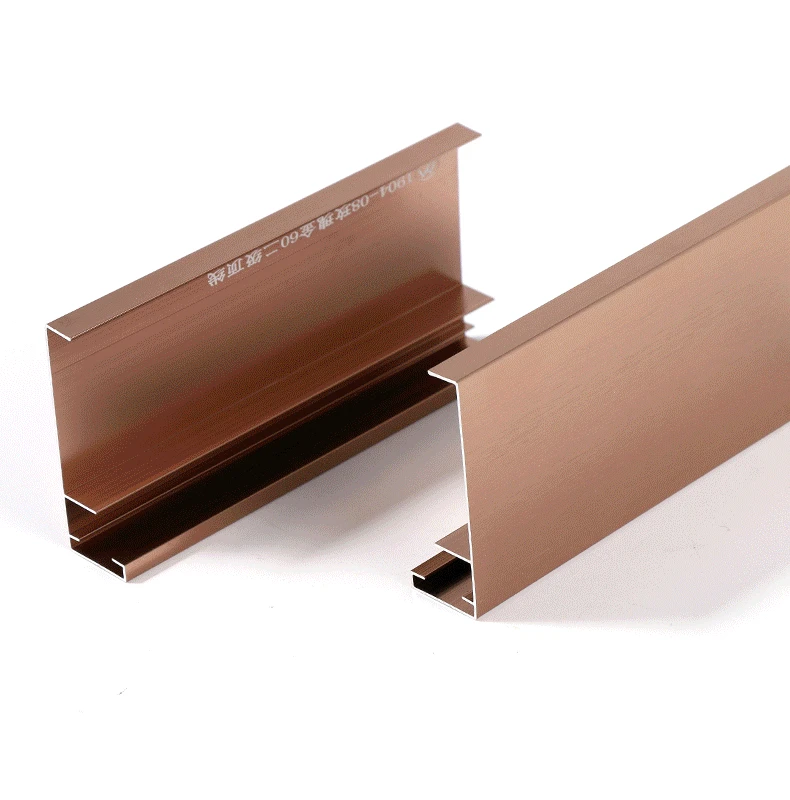

2. 1.75mm and 3.0mm Mould

-----Steel Material: S136

-----Size: According to sample size

----One Mould can produce different diameter filament for 3D printer

Such as : Normal specification 1.75mm 3.0mm ,2.0mm 2.85mm

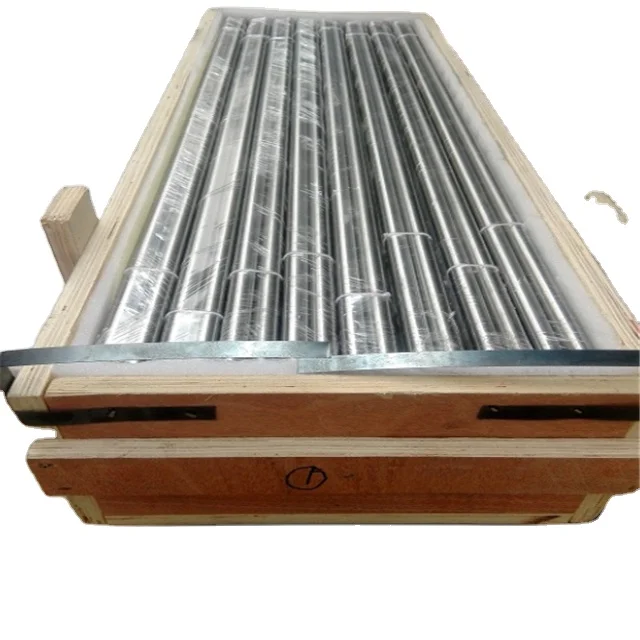

3. 6 meters Water Tank Cooling System

----Steel Material: S136

-----Size: According to sample size

----One Mould can produce different diameter filament for 3D printer

Such as : Normal specification 1.75mm 3.0mm ,2.0mm 2.85mm

4. Dryer +Laser X + Four Wheels Puller

----High precision guide pillar to system

---- Screw center high regulation, Zhang He adjusted

----High efficiency, multi wedge belt abrasion resistance of the surface traction

----The precision of Frequency inverter controller

----Motor power: 0.75KW

5. 8 meters Storage Device

---The maximum line length: 100 meters

----Motor control: 0.75KW

----Tension control: magnetic particle clutch

----Wire diameter: 4.0mm

----Spool: 250mm

6. Auto Metering machine:

Auto meter: Before winding machine, there are a device to calculate how many meter already produced.

7. Neat Winding Machine

---The function of automatic meter

---Tension control device

---Automatic cable winding

---Servo Motor Control System

---Motor Power : 0.75Kw*2SET

Dongguan Songhu Plastic Machinery Company is specialized in research , development and manufacture of plastic extrusion line. With more than ten years of experience, the plastic Tube Machinery made by our company has good production stability and dimensional decision and stability.

Perfect technical training and after-sales service is provided for every client .

1.Pre-sale :we would make deep communication to learn about sample requirement and actual production in workshops so we can guarantee the specialty of our products

2.Producing:Clients and his relevant technicians are welcome to our factory to monitor and give guidance, we also send periodic reports to your company each week.

3.Before delivery:clients should come and confirm whether the our machine is qualified and give approval to delivery

4.After delivery:after the machine reach the destination,our assembly engineers will reach your company to install the machine and do relevant training and guidance.

Sales Manager:Cherish Cai

Company Name: Dongguan Songhu Plastic Machinery Corp.

Address: 2nd Floor, Building C (Building 3), Kanghuier Industrial Park, No. 178, Yongjun Road, Shuilang, Dalingshan Town, Dongguan City, Guangdong,China

Website: https://www.songhu3dprint.com/

Email: cherish@ songhu3dprint.com

Whatsapp/Wechat/Telephone:+86-13266429826

Похожие товары

Затяжки холодный теплый кожи против старения, Красочные уход за лицом уход за кожей лица-7 видов цветов красный свет led корейский фотон терапии

18 мм простые плиты МДФ 1220/2440, плиты МДФ от производителя

Промышленный твердый высокоаммиачный латексный концентрат (латекс HA) 60% ДРК из малайзии

Высокое качество пигмент оптовая продажа palllate 18 видов цветов Матовая diy Тени для век Палитра предварительно окрашенная оцинкованная сталь) с низкой ценой

Синий пигмент Фталоцианин, синий порошок 15:3, цветной пигмент cas 147-14-8

Высококачественная потолочная металлическая алюминиевая плитка, отделка керамики

Горячая Распродажа, необычная и дешевая пустая стеклянная бутылка для красного вина в форме тигра 750 мл

Новые поступления

Новинки товаров от производителей по оптовым ценам