Чистой воды ro системы полиэтиленовый шланг 1/4 экструдер труб машина штранг прессования для лазерной трубки 3/8

- Категория: >>>

- Поставщик: Dongguan Songhu Plastic Machinery Corp.

Сохранить в закладки 1600279549418:

Описание и отзывы

Характеристики

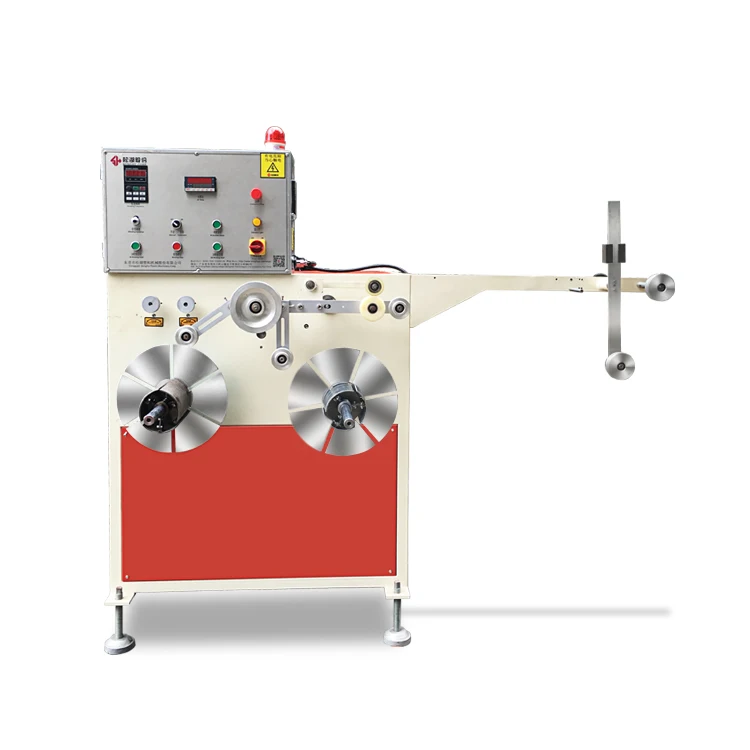

pure water ro system Polyethylene Tube Hose 1/4 pipe extruder machine extrusion machine for tube 3/8

Technical data of pure water ro system Polyethylene Tube Hose 1/4 pipe extruder machine extrusion machine for tube 3/8:

| Line Model | Screw Diameter | L/D | Production Speed | Produced Pipe |

| SHSJ55/ 65/80 | 55mm 65mm 80mm | 30:01:00 | 20-50m/min | 6.4*1.1mm |

| 9.6*1.5mm |

The extrusion liine mainly designed for making purified water tube, it is widely used for water purification system, and water dispenser and etc.

The Composition of Polyethylene Tube Hose 1/4 pipe extruder machine:

| NO. | Name | Quantity | Remarks |

| 1 | SHSJ Main Extruder | 1SET | According the capacity |

| 2 | Extruder Mould | 1SET | Different size |

| 3 | 6Meters Water Tank | 1SET | Cooling tank |

| 4 | Belt Puller | 1SET | 800mm |

| 5 | Winder Machine | 1SET | Double Station |

1.Single screw extruder: 1 SET

1)Model :SHSJ-55

2)Screw : Single

Diameter :55mm

L/D :28:1

Material :38CrMoAlA

Surface treatment:Polishing

Nitridation :Thickness : 0.4~0.7mm

Surface hardness:HV850~940

2.PE Tube Extruder Mould : 1SET

Extruder Mould

Raw Material:S136

Products Specification : 2 optional Diameter hole

| OD(mm) | ID(mm) | Thickness(mm) |

| Φ6.35 | Φ4.28 | 1.04 |

| Φ9.52 | Φ6.35 | 1.59 |

3.6meters automation circulation heating cooling water tank 1SET

------Water tank material: Stainless steel SUS304

------Water tank length: 6000mm (divided into two segments)

------ Automatic control of the heating water tank :1piece

------ Heating power: 2KWX220V

------ 90W, 220V high temperature water pump: 1 set

------Three dimensional adjusting tank frame 1 meters (around / about / on)

4.Belt Puller : 1SET

------Power of Motor : 0.75 Kw with double motor

------The length of Belt: 500mm

------The speed of puller 30m/min

------Raw Material of Belt PU

The Machine running will be very stable. It is easy to operate up and down.

5.Double StationAuto Winder 1SET

Tension Control Device 5N.m

Winding Spool : According Custom requirement

We have accumulated a lot of experience in precise extruder machine, especially for 3d printer filament extruder and medical tube extruder.

We just developed a new production line for 3d filament, which can produce dual-filament at same time, it maximize the production efficiency , the total line speed can be up to 130m/min with neat winding system . the diameter tolerance is 0.02mm. besides, we are also developing a new medical tube extruder, all frame are made of aluminum profile. It is not only comply with medical standard, but also more compacted and more attractive appearance.

More than 35% production line are exported to other countries, such as Indonesia, Vietnam, Thailand, USA,and some Europe countries.

Dongguan Songhu put great efforts on developing small and medium precision extrusion equipment, try to realize stable and high speed extrusion technology.

1. Seller supply full set of technical document, cutter and other full document (write in English) for the extrusion machine.

2. Seller supply training for buyer's staff until buyer can produce the eligible production independently.

3. Seller is responsible for installing, testing, adjusting and debugging the machines in buyer's factory.

4. Buyer should pay the expense for our engineers including for our engineer including round- way tickets, inland traffic, lodging and boarding fee when the machine is installed, tested and maintained.

5. Seller will go to install machines after the machine is arrived at buyer and buyer will have prepared all conditions (including power, water, compress air, tools and materials for producing pipe, etc) for installing and testing these machines. Buyer should pay 100 USD/day.

6. When installing, people of both sides cooperate well and carefully, buyer supplies convenient working condition, any problem, should discuss peacefully and kindly.

7. Buyer supply proper working tools, equipments and other conditions.

8. The expense including the accommodation and materials of the trial-run the machine for testing and other expenses(electric, water, air and worker) will be on seller's account, if the buyer or their representatives do the inspection of the machines before shipment.

9. Guarantee period: 12 months after shipment (the date of B/L)

Sales Manager:Cherish Cai

Company Name: Dongguan Songhu Plastic Machinery Corp.

Address: 2nd Floor, Building C (Building 3), Kanghuier Industrial Park, No. 178, Yongjun Road, Shuilang, Dalingshan Town, Dongguan City, Guangdong,China

Website: https://www.songhu3dprint.com/

Email: cherish@ songhu3dprint.com

Whatsapp/Wechat/Telephone:+86-13266429826

Похожие товары

Медицинский экструдер для кислородного шланга для изготовления мягких труб из ПВХ ТПУ ПП

UTT WX100S + WiFi контроллер, беспроводной контроллер, AP контроллер

Manunited One pcs WiFi6 точка доступа WiFi6 маршрутизатор сетчатый маршрутизатор WiFi6

Winnet 3G Роутер Wifi Lte модем Cpe с слотом Sim Caed Rj11 Rj45

Wi-Fi-роутер H720 lte с внутренней батареей

F5934 Wi-Fi промышленный роутер TP-link

2020 новый супер быстрый 5g sim роутер NSA & SA wifi6 N78 сетчатая Wi-Fi система

Новые поступления

Новинки товаров от производителей по оптовым ценам