Manufacture Custom Precision CNC Turning Milling Machining Service Aluminum Brass Stainless Steel Metal Parts

- Категория: >>>

- Поставщик: Huizhou Hongbang Hardware Technology Co. Ltd.

Сохранить в закладки 1600280204089:

Описание и отзывы

Характеристики

Business Type | Factory / Manufacturer | ||||||

Service | CNC Machining | ||||||

Turning and Milling | |||||||

CNC Turning | |||||||

OEM Parts | |||||||

Material | Aluminum: AL 6061-T6, 6063, 7075-T etc | ||||||

Stainless steel: 303,304,316L, 17-4(SUS630) etc | |||||||

Steel: 4140, Q235, Q345B,20#,45# etc | |||||||

Titanium: TA1,TA2/GR2, TA4/GR5, TC4, TC18 ,etc | |||||||

Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc | |||||||

Copper, bronze, Magnesium alloy, Delrin, POM,Acrylic, PC, etc | |||||||

Finish | Sandblasting, Anodize color, Blackenning, Zinc/Nickl Plating, Polish | ||||||

Power coating, Passivation PVD, Titanium Plating, Electrogalvanizing | |||||||

Electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench) | |||||||

Electro Polishing,Chrome Plating, Knurl, Laser etch Logo, etc | |||||||

Main Equipment | CNC Machining center(Milling), CNC Lathe, Grinding machine | ||||||

Cylindrical grinder machine, Drilling machine, Laser Cutting Machine,etc | |||||||

Product Description

Our Advantages

01 Professional hardware manufacturer

More than ten years of hardware parts processing experience, first-class production and processing team. From the customer point of view, the production of high quality, preferential products.

02 Perfect independent design and production capacity

We have a professional team of designers, as long as you provide samples, sketches or engineering drawings. Engineers can give satisfactory and professional design, production process, really solve your worries.

03 Perfect assembly system, real one-stop service

We has a large laser cutting machine, bending machine, OTC, CNC lathe CNC (turning), machining center machine (computer gong), punch, tooth tapping machine, and other series of hardware processing machines. As long as you have drawings, we can produce products.

04 Preferential price and short processing time

More than ten years of professional team, close cooperation. Truly achieve the control of quality, the saving of working hours, product quality assurance.

More than ten years of hardware parts processing experience, first-class production and processing team. From the customer point of view, the production of high quality, preferential products.

02 Perfect independent design and production capacity

We have a professional team of designers, as long as you provide samples, sketches or engineering drawings. Engineers can give satisfactory and professional design, production process, really solve your worries.

03 Perfect assembly system, real one-stop service

We has a large laser cutting machine, bending machine, OTC, CNC lathe CNC (turning), machining center machine (computer gong), punch, tooth tapping machine, and other series of hardware processing machines. As long as you have drawings, we can produce products.

04 Preferential price and short processing time

More than ten years of professional team, close cooperation. Truly achieve the control of quality, the saving of working hours, product quality assurance.

Company Profile

Huizhou Hongbang Hardware Technology Co. , Ltd. was founded in 2010, is a precision hardware parts production, processing, sales as one of the complex modern processing enterprises. Now the plant area of the company is 10000 square meters. Since its establishment, the company has attached great importance to talents, continuously studied the experience of hardware processing at home and abroad, and introduced a scientific management system, greatly improve the reliability and stability of spare parts. The company's existing lathe development and design personnel more than 30 people. Lathe, CNC, large-scale cutting machine, bending machine, punch and other large and medium-sized automation equipment a total of 52, equipped with tapping machine, cleaning machine, grinding machine, coax drying machine and other drilling equipment. Through years of development, the company has achieved car, Gong, plane, grinding, drilling, cutting, folding welding to the integration of processing. Is steadily to large-scale hardware development and manufacturing field. The products have been widely used in security inspection equipment, mobile phones, computers, drones, new energy vehicles and other cutting-edge technology products. Our products are exported to 130 countries and regions in Asia, America, Europe and Africa. In line with the "innovation and stability in the pursuit of customer first" purpose, Huizhou Hongbang Hardware Technology Co. , Ltd. will be in the future competition, break through the thorns

FAQ

1. who are we?

We are based in Guangdong, China, start from 2018,sell to North America(10.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

CNC and Sheet metal machining

4. why should you buy from us not from other suppliers?

Huizhou Hongbang Hardware Technology Co. , Ltd. was founded in 2010, is a precision hardware parts production, processing, sales as one of the complex modern processing enterprises. Now the plant area of the company is 10000 square meters.

We are based in Guangdong, China, start from 2018,sell to North America(10.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

CNC and Sheet metal machining

4. why should you buy from us not from other suppliers?

Huizhou Hongbang Hardware Technology Co. , Ltd. was founded in 2010, is a precision hardware parts production, processing, sales as one of the complex modern processing enterprises. Now the plant area of the company is 10000 square meters.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Похожие товары

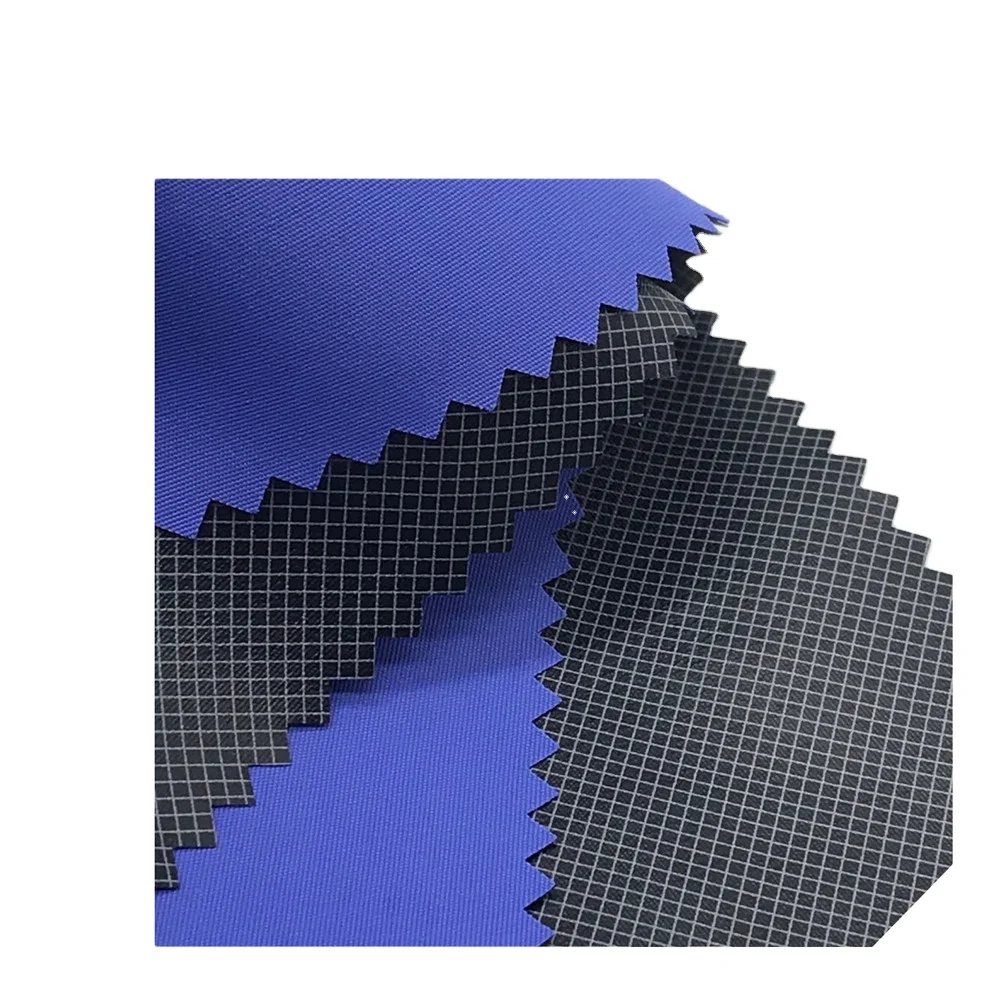

100% нейлоновая двухслойная ткань ripstop водонепроницаемая ветрозащитная дышащая ткань taslan с принтом ТПУ для курток обивки на открытом воздухе

0,99 $ - 1,20 $

Лидер продаж, роликовые коньки weiqiu, обувь, дешевые цветные колеса

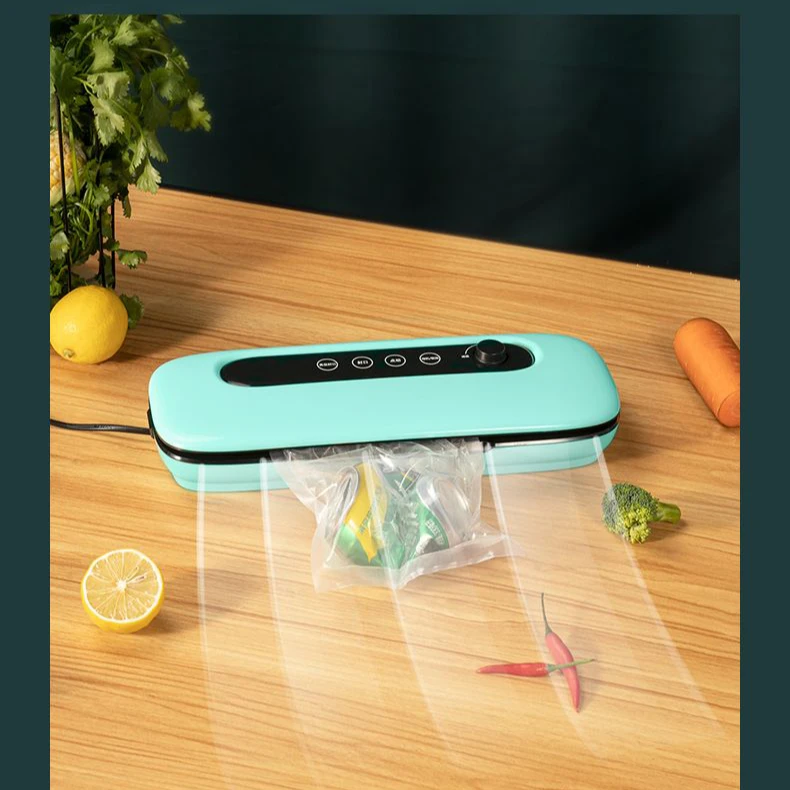

Все домашние мини-вакуумные пищевые уплотнители 220 В/110 В для пищевой упаковки

New design vacuum sealer food saver seladora a vacuo commercial single chamber vacuum sealer 220v for sous vide container

CE пищевая вакуумная упаковочная машина, Мини вакуумный упаковщик, вакуумная автоматическая упаковочная машина 110 В/220 В, новинка 2021

15,56 $ - 17,56 $

Сельскохозяйственный силиконовый поверхностно-активный адъювант проконазол фунгицид пропиконазол

Защитный барьер/баррикад от китайского производителя

21,26 $ - 28,15 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $