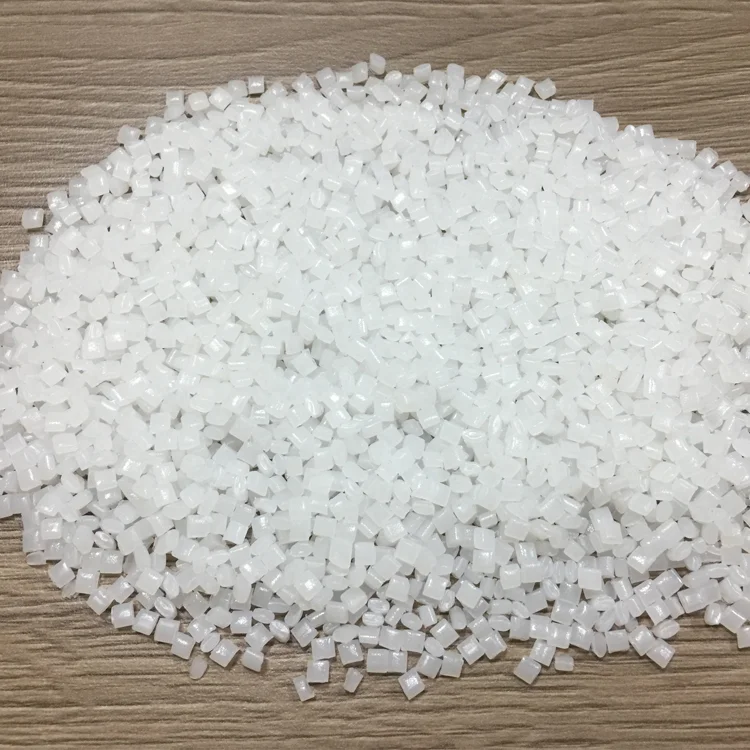

Полиэтиленовая смола белая пленка впрыскивающая Экструзионная Смола sinopec

- Категория: >>>

- Поставщик: Guangdong Intop Industrial Holding Ltd.

Сохранить в закладки 1600280951127:

Описание и отзывы

Характеристики

HDPE resin white graunles film grade blow injection grade extrusion grade sinopec

Properties:

High density Polyethylene (HDPE): is a highly crystalline non-polar thermoplastic resin produced through the copolymerization of ethylene and a small amount of α-olefin monomer. HDPE is synthesized under low pressure and is therefore also called low-pressure polyethylene. HDPE is mainly a linear molecular structure and has little branching. It has a high degree of crystallization and high density. It can withstand high temperatures and has good rigidity and mechanical strength and anti-chemical corrosion.

High density polyethylene for non-toxic, tasteless, no smelly white particles, melting point is about 130 ° C, relative density of 0.941 ~ 0.960. It has good heat resistance and cold resistance, chemical stability, but also has high rigidity and toughness, good mechanical strength. Dielectric properties, environmental stress cracking resistance sex also is good.

Specification:

HDPE | Unit |

|

Mass density | g/cm³ | 0.941-0.959 |

Melt flow Rate(190 Centigrade /2.16kg) | g/10min | ≤1.0 |

Tensile yield strength | MPa | ≥19.0 |

Flexural modulus | Mpa | ≥965 |

Elongation break | % | ≥400 |

Impact Embrittlement temperature | Centigrade | MAX -118 |

Dielectric Constant | 100KHZ | 2.32 |

1MHZ | 2.31 | |

Loss Tangent | 100KHZ | MAX 0.0001 |

1MHZ | MAX 0.0001 | |

Volume resistivity | OHM-CM | MIN 1x10 15 |

Specification:

- Film Grade

- Blow Grade

- Injection Grade

- Extrusion Grade

Film Grade

| Item | Test condition | Test Method | Value | Unit |

| Density | ISO 1183 | 0.944-0.955 | g/cm3 | |

| MFR | 190°C/2.16kg | ISO 1133 | 0.03-0.07 | g/10min |

| Tensile strength at yield | ISO 527-2 | 22 | MPa | |

| Elongation at break | ISO 527-2 | >350 | % | |

| ESCR | F50,50°C,100% | ASTM D-1693A | 1000 | h |

| VICAT | ASTM D-1525 | 126 | °C |

Application:

- Film grade is widely used in the production of packing bag, film and so on.

- Blow molding grade for making various bottles, cans, tanks , barrels Injection-molding grade is for making food cases, plastic trays, goods containers.

- Blow film product:Foodstuff packing bag,groceries shopping bags, chemical fertilizer

lined with film, etc - Extruded product: Pipe,tube mainly used in gas transportation, public water and chemicals

transport, such as building materials, gas pipe, hot water drain pipe etc: sheet material is

mainly used in the seat, suitcase, handling containers.

Should you have any queries, do not hesitate to contact me!

Click here for More Information

Похожие товары

Высокопоточный водяной насос для канализации 49LPM flojet по заводской цене, 12 В постоянного тока, водяной насос для ванной комнаты

SAILINGFLO 12 В постоянного тока высокого потока караван насос для воды/высокого потока 12 в водяной насос высокой емкости/12 Вольт Водяной насос давления 40PSi

Cheap Ce Approved 140H Motor Graders New 2018 Dong Feng Engine Motor Grader Xg3220C

Самовсасывающий диафрагменный насос LifeSRC 12 В и 24 В 80 фунтов на квадратный дюйм

12 вольт или 24 вольт мини водяной насос высокого давления для трубопровода venn усилитель

Оригинальный OEM 24V 8.5KW стартовый двигатель QDJ2918 C2874455 для дизельного двигателя Cummins

Мини прайс-лист DC 12 вольт глубокий скважинный Солнечный погружной водяной насос для сельского хозяйства

Новые поступления

Новинки товаров от производителей по оптовым ценам