Высокое качество хорошая цена ПВХ дерево пластик композитные дверные панели машина для производства EKO

- Категория: >>>

- Поставщик: Shanghai Yuhao Plastic Co. Ltd.

Сохранить в закладки 1600286035521:

Описание и отзывы

Характеристики

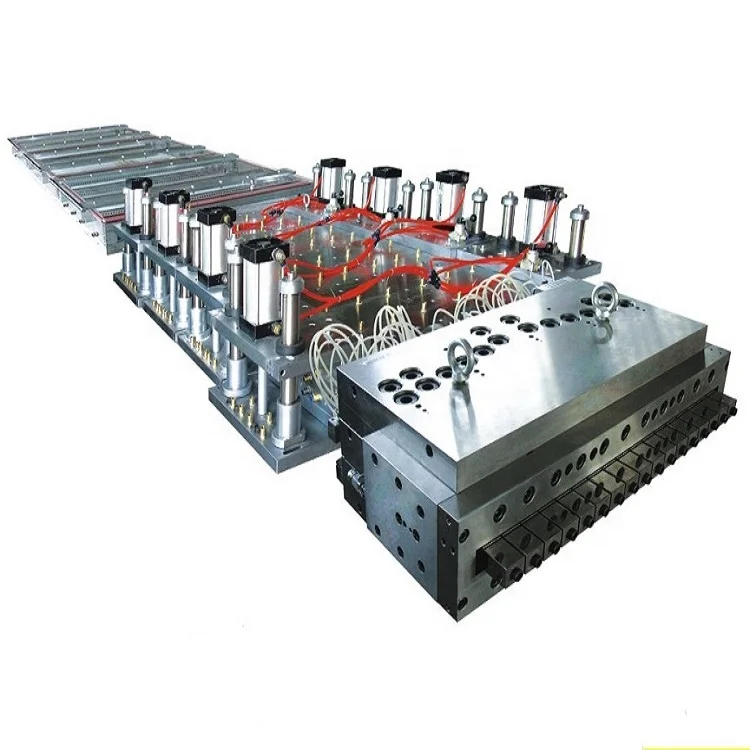

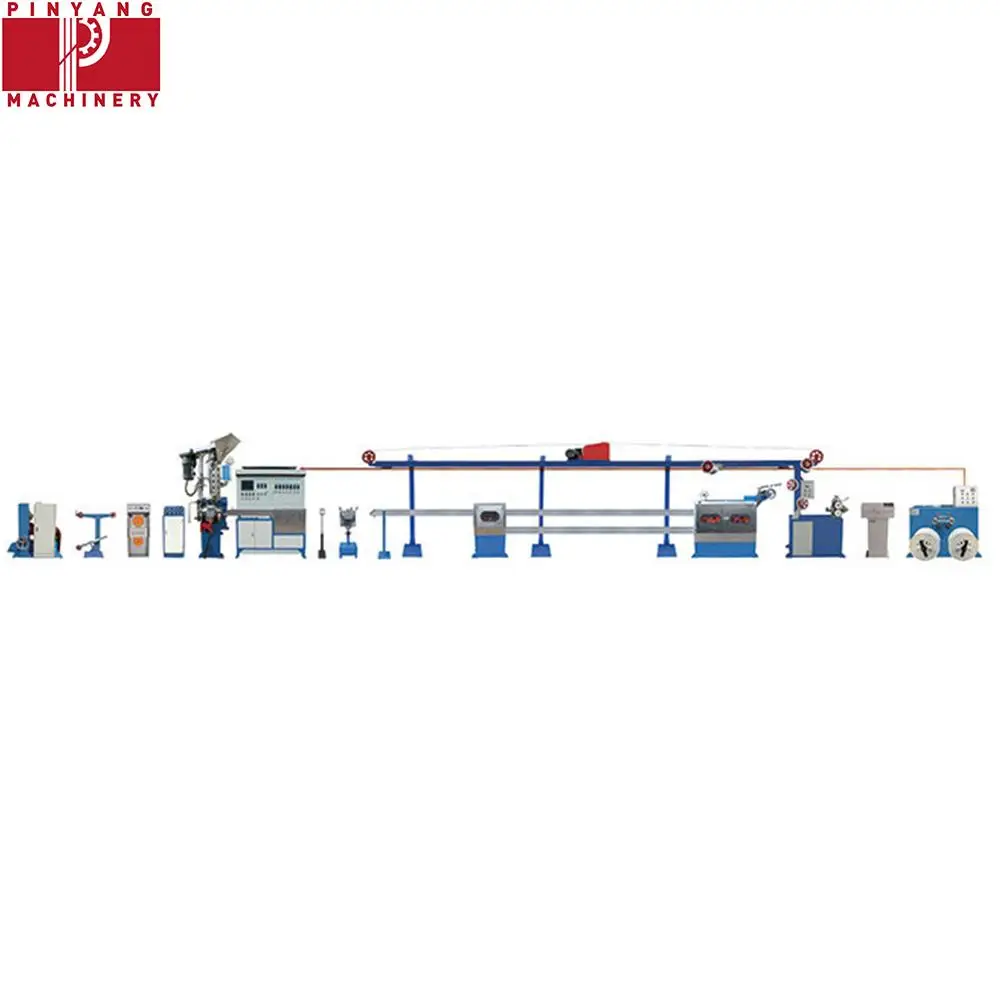

Wood Plastic Door Panel Extrusion Line | ||||||||

Equipment List | Auxiliary Equipment List | |||||||

1 | 92/188 Conical Twin Screw Extruder | 1 | HL500/1000 Mixer | |||||

2 | PVC Wood Plastic Door Panel Mould | 2 | PS700 Crusher & 700 Grinding machine | |||||

3 | YFD1000 Vacuum Calibration Table | 3 | KHAW-50D Air cooling chiller system with water pump | |||||

4 | YFY1000 Haul-off Unit | 4 | Door panel hot stamping machine | |||||

5 | YFQ1000 Cutter | 5 | Door locking hole drilling machine | |||||

6 | YFF1000 Stacker | ps: custom choose if any need | (Custom choose these ) | |||||

Max. designed output: 450 ~ 500 kg/h

Controlled by Imported brand AC frequency converter

Vacuum pump: 1 set

Vacuum pump power: 5.5 Kw

Vacuum degree: 0~ -0.075 Mpa

door panel making machine wood plastic composite door

High torque output

Water cooling device

Teeth hardening, precision gear grind treatment.

door panel making machine wood plastic composite door

door panel making machine wood plastic composite door

Main motor adjustment: Imported brand ABB inverter controlling

Power of heating oil:9 KW

Oil temperature range: 50~200℃

Power of motor: AC motor, 0.75KW

door panel making machine wood plastic composite door

Siemens PLC controlling system;

AC inventor: Imported brand ABB

Over-current prevention

Optical-electronic protective device for dislocation of screw

Oil-shortage alarming device

Material level alarming;

door panel making machine wood plastic composite door

Table width: 1800mm

Distance between aluminum track: 1100mm

Vacuum pump power and quantity: 5.5 KW x 2set 11 KW x 2set

Quantity of air nozzle: 60 pcs (marked in yellow)

Quantity of water nozzle: 60 pcs (marked in blue)

Consumption of cooling water:20 m3/h

Length of haul-off caterpillar:3000mm

Max. Cutting width: 1000mm

Max. Cutting height: 60mm

Form of stacker: Disassembled

Enterprise Strength melt blown fabric machine for face mask

door panel making machine wood plastic composite door

We have three companies respectively in Huangshi, Wuxi and Shanghai.

(One of the earliest extrusion mould pioneers in China)

1996---Hongda Plastic Mould Co., Ltd (PVC profile mould)

2002---Research and develop PVC WPC & PE mould

2003---Gain ISO9001(2000) & Sales exceed 5 million yuan

2004---Research PVC foam board

2005---Sales exceed 10 million & New factory(15000m2)

2007---Set up Shanghai eko Mould Co., Ltd

2008---Sales exceed 20 million yuan

2010---Produce wide board products

2013---Set up joint-venture in outer Mongolia

2013---Sales exceed 50 million yuan

2017---Set up (EKO) Wuxi Jiuke Mould Co., Ltd

2017---Sales exceed 80 million yuan

2018---Unified use the brand---EKO

Huangshi Hongda Plastic Mould Co., Ltd | ||||||

(EKO)Huangshi Hongda Plastic Mould Co., Ltd, located in Huangshi, the City of Mould, which is the leading enterprise in the mould industry. And its annual output can achieve 1,500 sets of mould.

Shanghai Yuhao Plastics Co., Ltd | ||||||

(EKO)Shanghai Yuhao Plastics Co., Ltd

A trading company based on Hongda and Eko mould company, which has a wide range, good quality, reasonable prices and stylish designs. Our products are extensively used in many different fields and industries.

Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs.

OUR CUSTOMERS, OUR FRIENDS

In the world, our products are exported to over 40 countries and districts.

We are proud to have friends all over the world.n

Testing & After-Sales Service

door panel making machine wood plastic composite door

Test is one of the most important element of the quality guarantee. We have a testing center and six advanced extrusion lines. Simulation in extrusion production testing offers guarantee for the machine before delivery, shorten testing time in your factory and help you to reduce the cost.

door panel making machine wood plastic composite door

Our experienced technicians will give you the best service. We promise: In China, 360 days guarantee period, sending perfect service to your factory within 48 hours. door panel making machine wood plastic composite door

door panel making machine wood plastic composite door

Professional Technology door panel making machine wood plastic composite door

door panel making machine wood plastic composite door

We provide the " turn-key-project " for the clients from material formula, operation technique,

extruder type selection to mould technique.

Vision: To be the top of extrusion mould manufacturer

Spirit: Professional, Efficient, Faithful

Style: Fast, Exact, Constant

Wrapped with film then packed by standard export wooden pallets for extruder and wooden boxes for moulds.

1. What kind of service can we expect from your side during this special period of pandemic ?

We all are trying our best to shorten the delivery time, and we'd love to offer some free medical supplies to help you fight against it. Regarding to our machinery, we are offering on line inspection test and on line instructions to help you install and start up the machinery. door panel making machine wood plastic composite door

door panel making machine wood plastic composite door2. What is delivery time of machinery and how about the payment terms ?

It will be different according to different model machines, usually for small ones need 45 working days. And the payment term is 50% as down payment and 50% before delivery. door panel making machine wood plastic composite door

door panel making machine wood plastic composite door

3. What is your main business scope ? door panel making machine wood plastic composite door

As a trading company, we offer whole package solution of profile extrusion machinery and extrusion product such as door panel, UPVC profiles,WPC foam board, SPC flooring, wall panels, PP board, PE decking and so on.

door panel making machine wood plastic composite door

4. Do you charge for the product samples of ? door panel making machine wood plastic composite door

We provide free samples ,but the freight charges need customers pay.

Похожие товары

Maquina extrusora пункт plastico 3 слоя co штранг-прессования ПВД пленки дуя машина экструдер полиэтиленовой пленки дуя машина

Пластиковая экструзионная машина, нейлоновая одноволоконная пряжа, экструдирующая машина для изготовления травокосилки для газонокосилки

ПВХ пластиковый экструзионный канал

Машина для производства Usb-кабеля, установка для производства алюминиевых кабелей, изоляционная пластиковая Экструзионная линия для покрытия проводов

ПВХ Экструзионная Машина для водопроводных труб/экструзионная машина для пластиковых труб из Китая по хорошей цене

Экструдированный полипропилен pe Нейлон выдувной экструзии пленки 3 слоя co штранг-прессования выдувной пленки дуя машина

Eco-friendly waterproof environment pvc plastic u profile formwork extrusions plastic panels

Новые поступления

Новинки товаров от производителей по оптовым ценам