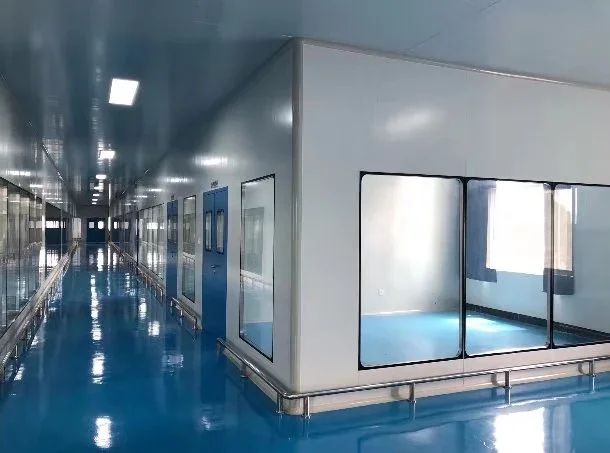

Высококачественная комната для чистки без пыли

- Категория: >>>

- Поставщик: Guangdong Jinyi Purification Technology Limited

Сохранить в закладки 1600287360127:

Описание и отзывы

Характеристики

Clean room design, manufacturing, construction

Jinyi Purification Technology Ltd provides one-stop service in clean room such as hospital operating room, ICU, ward, pharmaceuticals,bio-lab and so on. We provide all process from design, manufacturing, installation to after-sales service, The whole project contains the following parts.

We can provide clean room wall panel, ceiling panel, air circulation system, air shower, pass box, hepa filter, FFU, HEPA BOX, air diffuser, LED light etc for equipments.

Purification engineering design Cleanroom Solutions

(1) It is crucial to maintain a contaminant-free clean environment when manufacturing medical devices such as biological implants. This starts with the cleanroom design and management systems. The cleanroom design prevents outside contamination, while regular maintenance and sanitation upkeep minimize the risk of contamination originating within the cleanroom itself.

(2) Implants that are non-sterile or are awaiting sterilization should be subject to purification and clean packaging processes. This will allow for uniformity and control over product quality. When constructing a GMP Medical Instrument Cleanroom, a location should be designated for the packaging process, and processes should be implemented to ensure that products avoid contamination risk at all times.

(3) Procedures must be developed to control environments in which there exists a contamination risk to products. This includes any time personnel makes contact with a product, including when products are moved from one location to another.

Clean room rock wool, EPS, honeycomb sandwich Panel of ceiling, wall accessories:

Wall/ceiling panel | Machine-made or Hand-made sandwich board |

Clean room equipment | Air shower, FFU, Pass box, Laminar flow cabinet, hepa box |

Cleanliness | Class100-100000 |

Purification system | HVAC, or AC conditioner+FFU |

Floor | PVC anti-static floor or epoxy-based coating |

Other addessores | stalinite window, LED panel light, Door, Hand wash sink, storage/shoe cabinet etc |

Service | Design, manufacturing, construction |

sandwich panel | Double steel +Sulfur oxygen magnesium filler | Double steel+ rock wool filler | Double steel+ PU filler | Double steel+Mgo filler | Double steel+EPS filler | ||||

fire proofing | A | A | A | A | B | ||||

Weight Capacity | 180kg/m2 | 80kg/m2 | 100kg/m2 | 100-150kg/m2 | 80kg/m2 | ||||

Size | 1150/1180mm width, height customized | 1150/1180mm width, height customized | 1150mm, height customized | 1150/1180mm width, height customized | 1150mm,height customized | ||||

Steel thickness | 0.376mm, 0.426mm, 0.476mm, 0.526mm, 0.576mm | ||||||||

Thickness | 50mm, 75mm, 100mm | ||||||||

Installation | 1. we send engineer to customer side 2. constract out to construction team 3. customer send technicistto our company for free studying | ||||||||

Machine-made Mgo sandwich board( big weight capacity)

Hand-made sandwich board(easy to install)

Rock wool sandwich board(fireproof)

Machine-made EPS sandwich board(waterproof)

Похожие товары

Новый стиль портативный угольной гриль для барбекю уличный коммерческий коптильный квадратный

Новое поступление весенне-осенне-зимнее пальто мужская спортивная куртка по индивидуальному заказу от производителя дизайнерская флисовая большого размера мягкие флисовые

Уникальный Автоматический однофазный стабилизатор напряжения с 1k на 2k гарантированного качества

Angelbella Ombre кератиновые волосы для наращивания, 100% натуральные человеческие волосы с неповрежденной кутикулой

Спортивные комплекты одежды для женщин вересковая версия для спортзала йоги

Машина для измельчения чеснока/машина для измельчения чеснока

Резиновый расширительный ремень от производителя, резиновый ремень с фланцем

Новые поступления

Новинки товаров от производителей по оптовым ценам