Высокоточный токарный станок с ЧПУ для ремонта колес

- Категория: >>>

- Поставщик: Zhongyou Heavy Industry Machinery Equipment Co. Ltd.

Сохранить в закладки 1600288792152:

Описание и отзывы

Характеристики

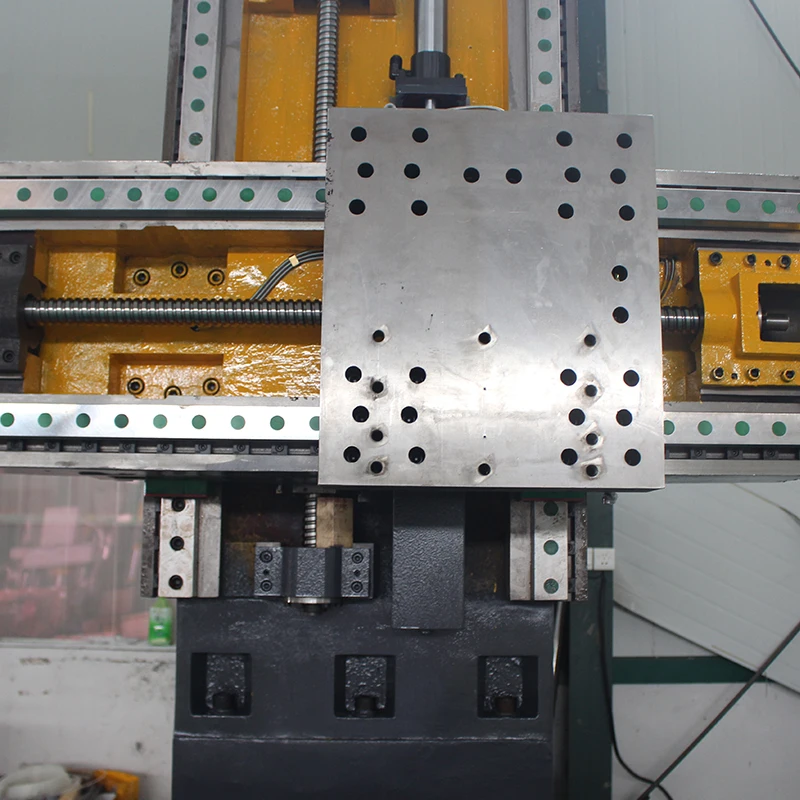

High precision wheel repair cnc vertical turning metal aluminium lathe

Product Description

This machine is an automatic vertical cnc lath for machining the inner and outer cylindrical surfaces of the parts, conical surface, end surface, grooving and chamfering. It is especially suitable for brake hubs, drums, clutch pressure plates and flywheels. Processing of parts such as shells.

The machine covers a small space, can be designed to meet different space request. The counterweight is used to balance the z-axis with a large load bearing capacity,which effectively ensures the influence of the two axes due to different stress structures. The cutting feed in the process of wheel repair can keep sensitive control response and achieve the perfect wheel milling effect.

Main Features:

1.The base, column and sliding seat are all made of high-grade gray cast iron, and have been tempered to ensure that the machine tool has high strength and long-term accuracy and stability.

2. X and Z axes adopt precision linear guide ways.Ball screws are pre-extended. It makes the machine with high rigidity and accuracy.

3. 8-station hydraulic turret is reliable,high efficient and good performance.

4. The spindle is of high rigidity construction to provide variable speed to realize constant linear speed cutting and heavy cutting.

5.The machine tool spindle adopts wide-area and high-torque servo motor drive, which can be used for low-speed and high-torque,

heavy-duty cutting, and high-speed cutting. At the same time meet the needs of roughing and finishing

6. Automatic centralized lubrication with full sufficiency and reliability.

Specification

Specification | Unit | VT75 |

Max.Swing diameter | mm | 750 |

Spindle speed | rpm | 50~1500 |

Cutting feed speed | mm/min | 0.1~1000 |

Vertical moving distance of tool holder | mm | 700 |

Tool rest horizontal moving distance | mm | 700 |

Longitudinal fast moving speed | mm/min | 16000 |

Transverse fast moving speed | mm/min | 16000 |

Tool holder form | horizontal | |

Diameter of hydraulic chuck | mm | 630 |

Main motor power | Kw | 22 |

positioning accuracy | mm | ±0.008 |

Re -positioning accuracy | mm | ±0.008 |

Machine size | mm | 2200×1900×3200 |

Application

The machine especially suitable for processing wheel hub, brake hub and other types of short shaft, pump body, disc parts.Suitable for multi-variety, small and medium-sized batch parts processing characteristics, is the automobile, agricultural machinery, engineering machinery, electrical machinery and other industries parts processing preferred equipment.

Packing & Delivery

Packaging Details:

Internal plastic moisture-proof anti-rust packaging,

External wooden packaging,

Exclusive container transport.

Our service

Our services are divided into pre-sale, sales, after-sale three parts.

Pre-sale:to provide detailed advice, the program recommended to the factory inspection, as far as possible to meet your questions and needs.

Sales:can support samples, support diversified payment methods, the solid forklift tire press machine production process transparent, standardized and quickly stocking.

After-sales:support diversification guidance, training, voice and video images, and even solid forklift tire press machine overseas site installation, on-site training, home maintenance, continuous return visit customers concerned about the use.

Company Profile

Certifications

Our company has passed the ISO quality management system certification,Products are exported to more than 50 countries and regions including Europe, America, Asia, Oceania and Africa.Has a number of product patents and honor certificates,is a continuous innovation machinery and equipment company.

FAQ

1:How can I choose the most suitable machines ?

A: Please tell me your specifications ,we can choose the best model for you , or you can choose the exact model .You can also send us the products drawing ,we will choose the most suitable machines for you .

2: Where is your factory located? How can I visit there?

A : Our factory is located in Tengzhou City ,Shandong Province,277500 China. You are warmly welcomed to visit us.

3. What is your trade terms?

A : FOB, CFR and CIF all acceptable.

4: What's the Payment Terms ?

A : T/T ,30% initial payment when order ,70% balance payment before shipment ;Irrevocable LC at sight .

A: Please tell me your specifications ,we can choose the best model for you , or you can choose the exact model .You can also send us the products drawing ,we will choose the most suitable machines for you .

2: Where is your factory located? How can I visit there?

A : Our factory is located in Tengzhou City ,Shandong Province,277500 China. You are warmly welcomed to visit us.

3. What is your trade terms?

A : FOB, CFR and CIF all acceptable.

4: What's the Payment Terms ?

A : T/T ,30% initial payment when order ,70% balance payment before shipment ;Irrevocable LC at sight .

Похожие товары

Лидер продаж, буровое долото R32 R35 64 мм 76 мм 102 мм, купольное сверло для сверления

78,00 $ - 79,00 $

Новинка 2020 детская развлекательная игрушка Волшебная водная книга с мультяшным рисунком и

1,10 $ - 1,20 $

Токарный станок для металла Hobby Arm Robot

C6260Y Горячая продажа китайский поставщик точный металлический токарный станок для продажи

4 800,00 $ - 5 000,00 $

Оригинальные Конические Роликовые Подшипники NSK KOYO TIMKEN LM48548/LM48510 LM67048/LM67010

1,00 $

Высокоточный токарный станок с ЧПУ TCK6340, наклонный токарный станок, металлическая наклонная кровать, токарный станок с ЧПУ

10 980,00 $

2020 роскошная коробка для часов и бумажный пакет, женские часы и браслет в коробке

5,10 $ - 5,70 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Hantek щупы осциллографа автоматический Тестовый Кабель Ht30a Bnc к банану двойная Банановая головка многоцелевое автомобильное

3,10-3,44 $

Горячая распродажа ручная работа традиционная деревянная урна для домашних животных квадратная коробка золы собак и кошек персонализированная Лучшая цена

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $

Irdmco экологически чистый минималистичный прямоугольный деревянный ящик для хранения стеллаж поделок и детских игрушек Домашняя мебель гостиной

Технология сенсорных перчаток и аксессуары для детей от дождя холода M725132-334

1,07-1,40 $

GY6 6 Pin AC гоночный CDI для CG125 CG250 двигателя Dirt Pit Bike ATV Quad

Парик из синтетического волокна для косплея

9,85-12,66 $

Прямая Продажа с фабрики 65 см Модернизированный подвесный стерео голографический проектор светодиодный вентилятор высокой четкости экран 3D дисплей

155-185 $