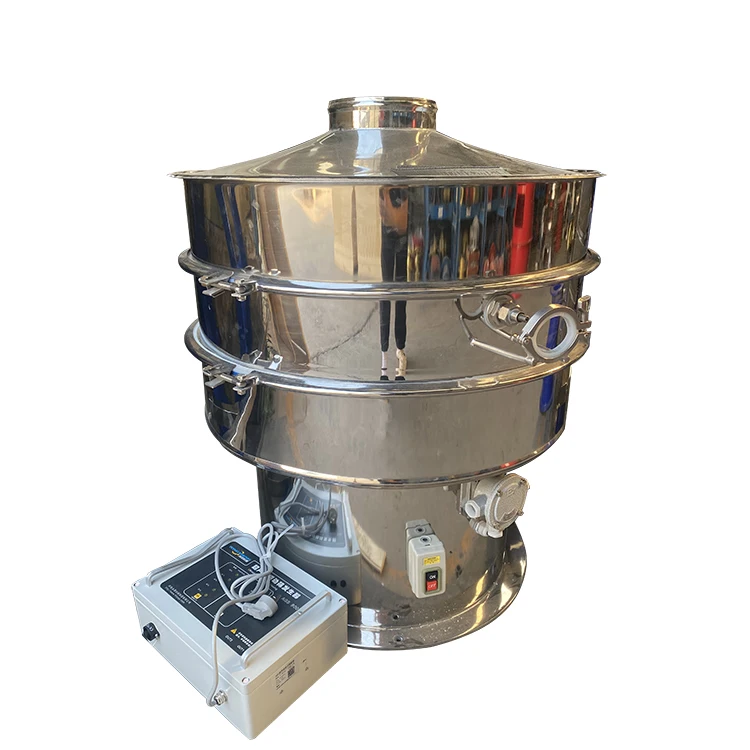

Аппарат для сита порошка вибрационный просеиватель

- Категория: >>>

- Поставщик: Henan Remont I/E Co. Ltd.Henan Ltd.

Сохранить в закладки 1600293063051:

Описание и отзывы

Характеристики

| Comparison of the advantages of Rotary vibrating screen |

(Take starch as an example)

| Tumbler screen machine | Rotary vibrating screen | |

| Production ratio | The capacity of one set of diameter 1800mm tumbler screen machine (60-80mesh) is about 6 tons per hour | The capacity of one set of diameter 1800mm rotary vibrating screen (40-60 mesh) is about 3 tons per hour. |

| Energy consumption ratio | When the same capacity is achieved, the tumbler screen machine has one power of 3kw.

As a result, one set tumbler screen machine can save 60 kwh of electricity per day, and nearly reach 2000 kwh per month. | While the rotary vibrating screen needs two power of 6 kw. |

| Performance ratio | Our company's tumbler screen machine is equipped with ABB motor, NSK bearing, the 24-hour working all the time and zero failure rate for five years. | Due to the high frequency centrifugal vibration, the rotary vibrating screen often has problems such as motor bearing failure, frame array, and screen damage. |

| Noise ratio | The noise of tumbler screen machine is less than 60 decibels | While the noise of rotary vibrating screen is above 80 decibels. |

| Purchasing cost ratio | The production capacity of one utmbler screen machine can replace at least two rotary vibrating screens for the same model, and the purchase price is only the purchase cost of two sets vibrating screen. | |

| Introduction of powder sieve machine vibrating screen |

MPH series tumbler screen is special designed a highly efficient screening machine to meet the large production, high precision manufacturers. It is by far the most effective exercise simulates the manual screening of effective principles(screening accuracy, efficiency and screen life are 5-10 times of normal circular screen), it meets all fine and ultrafine range of powder and particulate material, particularly suitable material that difficult to screen.

| Specification of powder sieve machine vibrating screen |

1.Function: screening and filtering any powder or particle material

2.Diameter: 1000mm to 2200mm

3.Sieve layer: 1-5 layers.

4.Screen size range: 10mm-500 mesh.

5.Driven mode: vibration motor driven.

6.Material: carbon steel, material contact parts stainless steel or all stainless steel.

7. Screening accuracy, efficiency and screen life are 5-10 times of normal circular screen.

Different Model Different Capacity

| Model | Power | Weight | Valid Area(square meter) | Diameter of Screen Mesh(mm) |

| MYB 1000 | 1.5 kw | 410 kg | 0.74 | 950 |

| MYB 1200 | 2.2 kw | 460 kg | 1.01 | 1150 |

| MYB 1600 | 3.0 kw | 485 kg | 1.93 | 1550 |

| MYB 1800 | 3.0 kw | 800 kg | 2.46 | 1750 |

| MYB 2000 | 4.0 kw | 1250 kg | 3.05 | 1950 |

| MYB 2200 | 4.0 kw | 1650 kg | 5.18 | 2150 |

| The relevant pictures of powder sieve machine vibrating screen |

| Applocation of powder sieve machine vibrating screen |

Tumbler screen is widely used in chemical, food flavors, plastics, mining, medicine, wood and plywood,metallurgy, rubber, feed, fertilizer, sugar, salt, or renewable industries.

Похожие товары

Завод 20 т/ч древесные чипы Gyratory сито Rotex экран

EPA Бензиновый очиститель почвы песок гравий аппарат для очистки компоста

Ультразвуковой классификационный скрининг Вибрационный экран роторный вибрационный фильтр для очистки муки

Машина для просеивания порошкового покрытия из песчаной глины

Линейный Вибрационный гравитационный встряхивающий стол сортировочный прямой экранный сепаратор машина для обработки семян сои

Большая Емкость для обработки древесной щепы

Высококачественный линейный вибрационный экран большой емкости пескоомыватель для добычи/песка

Новые поступления

Новинки товаров от производителей по оптовым ценам