Высокотермостойкие керамические бусины шлифовальные Изоляционные Бусины

- Категория: >>>

- Поставщик: Zhejiang Humo Polishing Grinder Manufacture Co. Ltd.

Сохранить в закладки 1600301831468:

Описание и отзывы

Характеристики

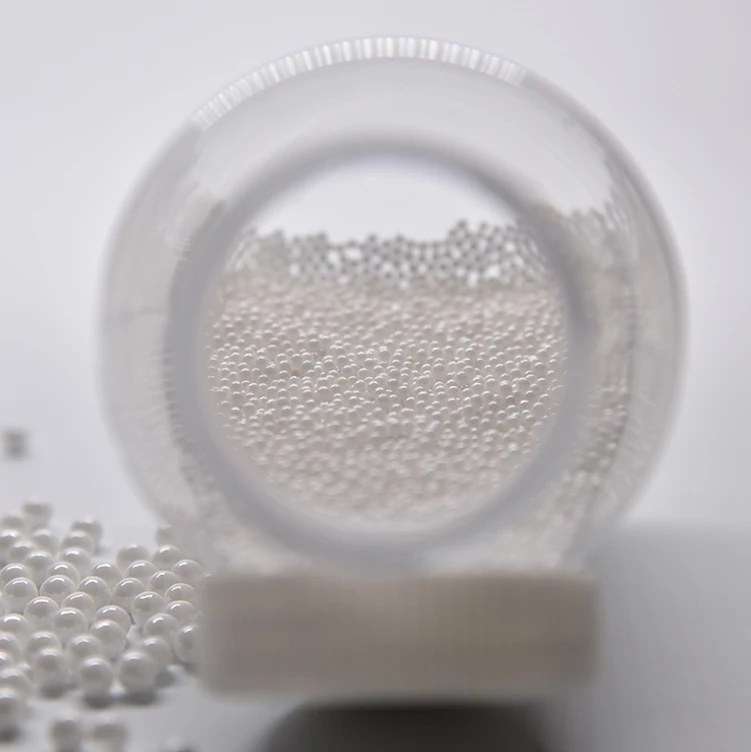

High heat resistant ceramic beads ceramic grinding Insulating beads

It can be used for superfine grinding of relatively soft nonmetal powder such as Superfine heavy CaCO3,kaolin , talc, etc.

This kind of micro bead on one hand can satisfy the above grinding of the nonmetal powder body on the aspect of property: it has the advantage of lower price.

It may be said decent product with reasonable price,and is the first choice for many superfine grinding companies and grinding paint coating factories.

Humo Company applied unique roll polishing technology, which ensures the sphericity and density of the product, and without cracking. The company applies advanced kiln sintering technology; and with a longtime of high temperature sintering, the wearing-resistance microcrystal structure has formed. The property stability during the procedure is ensured. The raw material with high-white degree, high finesse degree is applied in order to resist the pollution of the materials. We can select grinding medium with different density according to different grinding equipments and objects customers have. (And can also custom made the beads with needed density and specification required by customers).

ZR-320 Zr ceramic beads with high wearing-resistance

Matching application::It can be used with various kinds of grinders, for high-efficiency grinding of the powder body with solid content in the range of 40-75%

Application range:It is widely used for the grinding and distribution of paint, printing ink, pigment, farm chemical, titanium pigment, heavy calcium, kaolin, magnetic powder, etc.

Technical Parameter:

Compostion | Zr02≥20%,Si02≥30% | 0.5~0.8 0.8~1.0 1.0~1.2 1.2~1.5 1.5~2.0 2.0~2.5 2.5~3.0 3.0~3.5 3.5~4.0 …~30 Various specification products |

Density | >3.2g/cm³ | |

Bulk Density | >2.0g/cm³ | |

Hardness | >580N |

Our laboratory services are available to you at no cost. Mass Finishing and determination of Process Capability allows you to use the right media to ensure consistent production capability and built-in reproducibility of your manufacturing processes. We will work with you to determine the best media and the best processes for your parts. This step can result in:

- Reduced Cycle Times

- Improved RMS Finishes

- Reduced Finishing Costs

- Access to Latest Technology

- R & D for Special Process Media

Mass Finishing describes a mechanical process where large amounts of parts are economically processed to achieve one or several surface improvement functions. These surface improvement functions include:

- Cleaning

- Deburring

- Surface refinement

- Inhibiting

- Drying

These functions are not independent of each other. It is common to have several or all of these functions take place in a single mass finishing process.

Process Capability is the measured, built-in reproducibility of the product turned out by the process. Such a determination is made using statistical data, not wishful thinking. Statistically determined limits are compared to specification limits to decide if a process can consistently produce acceptable product. Process capability is best established through closely monitored testing and recording of data over a set period of actually production.

Похожие товары

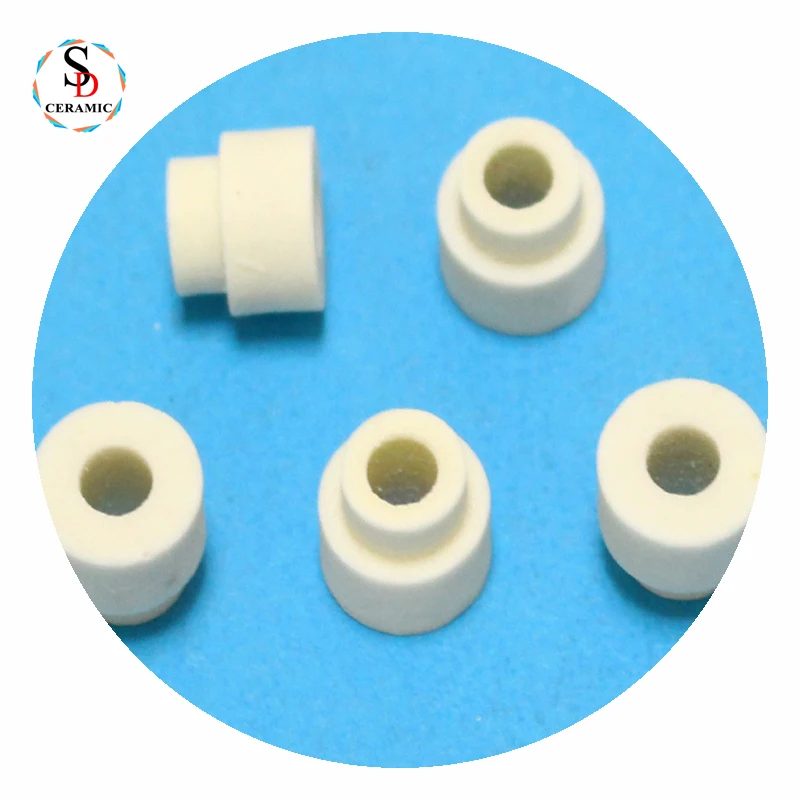

Керамические изоляторы, керамический изолятор, Керамические Изоляционные Бусины

Производитель высококачественных керамических ленточных нагревателей, соединяющихся изоляционных бусин

Производитель Керамических изоляционных шариков 95%, Алюминиевые шарики, изоляция алюминиевых керамических шариков

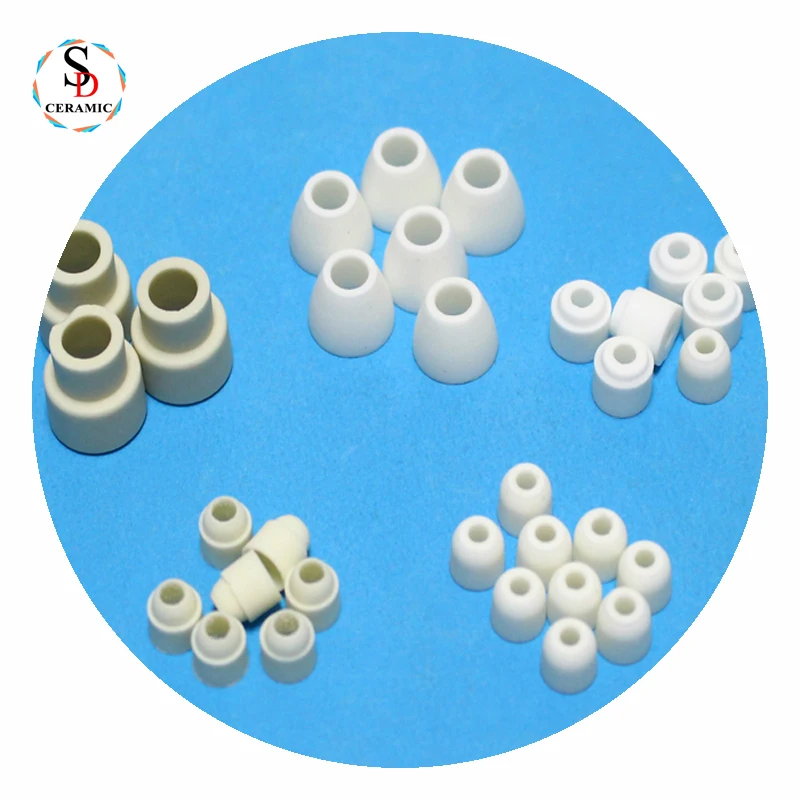

Изоляционный стеатита в форме спирали из керамической проволоки изоляция бусины

Керамические купольные блокирующие Изоляционные Бусины Steatite C221

Керамические купольные блокирующие Изоляционные Бусины

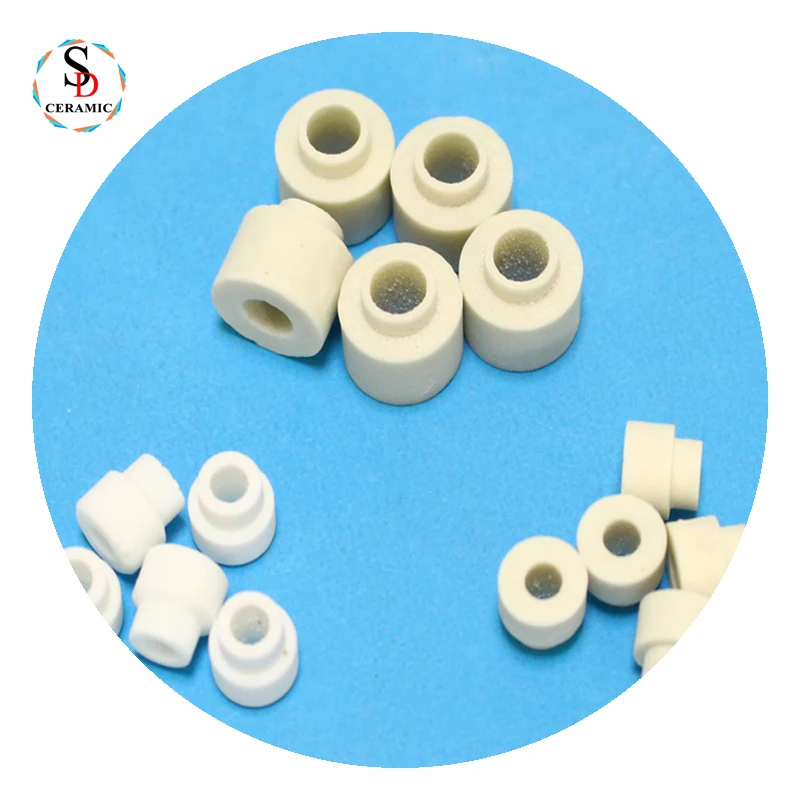

Разумные цены, ажурный керамический шар Al2O3, активированный пузырь из алюминия из Китая

Новые поступления

Новинки товаров от производителей по оптовым ценам