Высокоэффективный профиль коробки Zhongtuo стальной кровельный лист с высоким ребром

- Категория: >>>

- Поставщик: Cangzhou Zhongtuo International Trade Co. Ltd.

Сохранить в закладки 1600306947007:

Описание и отзывы

Характеристики

Zhongtuo High speed trapezoidal roofing sheet forming machine is designed to produce metal roofing sheet in batch fully automatically. We can customize the machine according to your profile drawings. here is some profiles for your reference.

The work flow of roll forming production line.

10T Hydraulic Decoiler

Hydraulic Decoiler with loading car | Hydraulic entry loading car | A. The car can move levelly and vertically, which is convenient for putting the steel coils into the de-coiler. B. It is driven vertically by hydraulic cylinder with 5 guide pillars C. The level movement is driven by motor D. Capacity:10T Function: It is used to lift up and down, move forward and back to make it easy to load the coils on decoiler. Hydraulic controls lifting, motor drives moving. The car is controlled on the control panel of hydraulic decoiler. Its moving speed is 6-7 m/min. When the coils on decoiler, the car will return back to the start position. It can also carry back the unfinished coils from decoiler. | |

Hydraulic decoiler | A. Supporting the coils and doing uncoiling. The capacity is 10Tons(max). B. It adopts the hydraulic oil cylinder to make the decoiler expandable and fit to the inner diameter of coils. It is equipped with the cantilever. C. Motor drive the coils running and can do forward and reverse running as well as do the decoiling with tension. D. The core can ensure the expand range φ450 of the coils inner diameter. It will provide the rubber band to ensure the 550 mm diameter. Carrying capacity: 10 tons Max coil width: 1250 mm Feeding speed: 0-40 m/min (adjustable) Driving motor power: 5.5 kw Hydraulic motor power: 3 kw E. Structure: welding by the steel plates and profiled bar. Remark: The speed sensor of the decoiler enables the decoiler to adjust the speed to match up the production of the roll forming machine automatically. |

The Main Forming Machine

Roll forming machine

| Feeding device | Steel plate welded platform to carry the sheet and feed into roll forming system, have the bearing inside to protect the edge of the steel sheet. |

Feeding width is adjustable with the handle wheels | ||

Rolling shaft | Shaft material:40Cr STEEL | |

Shaft diameter: 80 mm | ||

Tempering treatment to prevent deformed and improve hardness | ||

Roller | Material: high grade 45# steel | |

Chromed treatment (Chrome thickness:0.05 mm), make the rollers surface more smoothly, improve the hardness and prevent abrasion, anti corrosion increase of service life | ||

Rolling station | 20 rolling stations (the rolling stations depends on the profile drawing of roofing sheet) | |

Rolling type: separate rolling design concept, it can release internal stress from the sheets, then the sheet will be in good shape and high precision. | ||

Work speed | 0-45 m/min | |

Machine structure | Iron casting Vertical arch frame structure | |

Machine basic frame | Hot rolled H-beam | |

We will make diagonal bracing inside the frame, to strength the structure and keep the whole plate in same horizontal plane | ||

Voltage | 415V 50HZ 3P | |

Work power | 11 kw | |

Rolling spacer | Anti rusty treatment, Electroplate (chromed) | |

Transmission | Gear box transmission(bevel gear inside) | |

Advantage: can improve the speed directly after cutting |

PLC Control System

Control system | Frequency brand | Delta (original) |

PLC brand | Delta (original) | |

Frequency brand | Delta (original) | |

Screen type | Touch screen, also have buttons on the panel | |

Screen language | English/Chinese | |

Cut command | Yes | |

Profile length set-up | Yes | |

Batch quantity program | Yes | |

Low pressure electric part | Schneider brand | |

Encode | Omron brand |

Hydraulic Servo Cutting System

Cutting system | Work type | Hydraulic cutting, servo cutting system | |

Driving method | By pillar type Cylinder | ||

Cutting device structure | Pillar type | ||

Noted: please fill the lube before start the machine the first time | |||

Hydraulic motor power | 7.5 kw | ||

Servo motor power | 5.5 kw | ||

Hydraulic oil

| Hydraulic oil number: 46# | ||

Quantity: around 100 Litre | |||

Maintain: change the hydraulic oil every 2 years | |||

Cooling method | Equipped with fan on the tank, in case the oil temperature getting hot when the machine working for hours continuously, ensure the hydraulic oil in a constant temperature to have enough power for cutting device | ||

Cutter material | GB-Cr12 with heat treatment | ||

Cutting length tolerance | ±1mm/3m | ||

Cutting feature | Steady and safe working condition | ||

Oil tube and wires connection | All the tubes and wires will be marked by the numbers or letters, So that it will be very easy to connect for the new. |

Automatic stacker with conveying platform

Payment Term and Warranty

1.Payment terms:

-30% by TT for the advance payment at order

-70% by TT after inspection in China

2. Delivery: Max.45 working days after the advance payment.

3. Validity time: 15 days since the quote date.

4. After-sales service

A: Warranty: One year ,and we will provide the technical support for the whole life.some spare parts are available.

B: Training and service: the buyer should charge of visa, round-trip ticket, food and accommodation overseas and USD80/person/day for salary. Also need the buyer arrange some workers to help our technician for installation and commissioning

C. The advantage of my factory: we have a team of skilled engineers and one group for after-sale service.

D: we will provide you the layout for installation in English.

Похожие товары

Лидер продаж энергосберегающие долговечные двигатели для автомобилей по новой

Кардамоновые растения от производителя, китайский кардамоновый зеленый

Школьная форма из спандекса, подходящая ткань для одеяний, среднего веса, Toyobo, с застежкой на английском языке

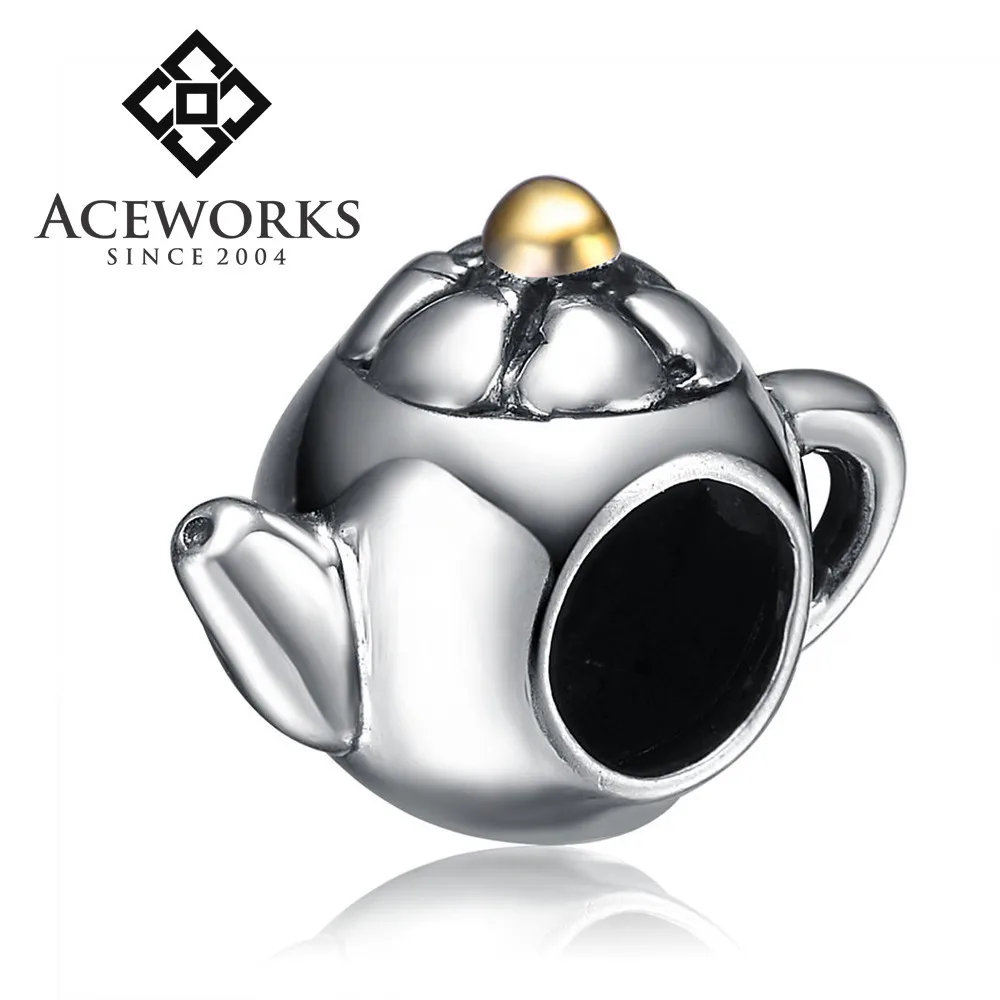

Бусины из серебра 925 пробы с золотым покрытием, в европейском стиле

UGO новый продукт рекомендации: розовый игровой комплект для девочек, оптическая мышь DPI, классная механическая клавиатура с подсветкой

2021 Высококачественная Точная механическая промышленная распределительная коробка с

Измельченные наполнители для мешков из пены с эффектом памяти

Новые поступления

Новинки товаров от производителей по оптовым ценам