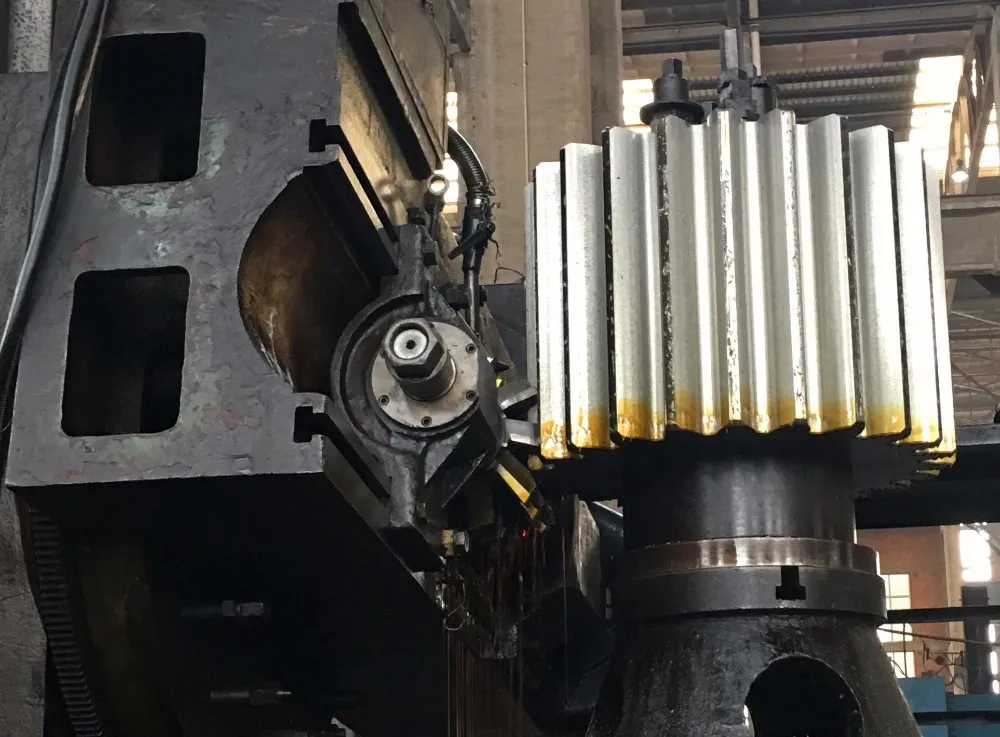

Luoyang Wangli Heavy Machinery Co.,Ltd, established in the year of 2002, mainly engaged in the designing and manufacturing of large machinery components and non-standard machinery parts in five kinds. 1.Spare parts of Engineering machinery (such as dragline excavator, power shovel,driving machinery): rail, speed reducer,segmented gear ring,etc. 2. Spare parts of Cement machinery (such as bearing, roller shaft, thrust roller, liner plate, trunnion, inlet device, shell,kiln tyre) and Environmental protection machinery 3. Non-standard Large module gear,gear shaft,gear rack,arc gear,herringbone gear,herringbone gear shaft and so on 4. Customized large non-standard equipment and spare parts, mining machinery parts, petroleum & chemical machinery parts 5. Hot-forging die, castings and forgings etc. 6. metallurgy machinery parts. The products are mainly used for many fields, petroleum, cement, steel mill, power plant, sugar factory etc. It has passed the certification of ISO9001-2008 in 2005. China is the world factory. Luoyang is the industrial base of machinery in China. We Wangli Company are a pioneer of machinery industries in Luoyang. 12 engineers of our company are come from various field of material research, forging & casting, heat treatment, machining, gear, bearing, inspection (UT, MT, PT, RT), assembly with at least 30 years working experiences at famous state-owned large enterprise for big nonstandard machinery spare parts, we can understand your drawings well.