Многофункциональное высокочастотное Индукционное нагревательное сварочное оборудование

- Категория: >>>

- Поставщик: Shenzhen Canroon Electrical Appliances Co. Ltd.

Сохранить в закладки 1600313479891:

Описание и отзывы

Характеристики

Multi functional high frequency induction heating welding equipment

Contact: Sandy Liu

Mobile | Whatsapp | Wechat: 0086-13715137235

Brief introduction of

New Generation | Intelligent | Digital | Induction Heating | CR2100 system

Your reliable heating expert in 21Century

| Brand | Canroon (manufacturer) |

| Model | CR2100- |

| Tech | digital control | module design | induction heating |

| Control Mode | power control mode | temperature control mode |

| Heating Material | all metal: iron, steel, copper, brass, zinc, aluminum, silver, gold, etc |

| Applications | brazing, curing, hardening, annealing, shrink fitting, etc |

Typical brazing case:

short circuit ring, copper wire, rotor bar, heat exchanger, etc

Advantages of Canroon CR2100 series product:

1. various model for choice

Split type is provided to work with your current chiller.

All-in-one type is designed with built-in chiller, no need for external cooler, less space;

2. high temp | fast heating

Able to reach above 1000℃ within seconds, save our precious time, improve your work efficiency;

3. easy operation

CR2100 can be easily start/stop manually, and scan on workpieces surface to do local heatng.

It can also be integrated into robot arm to serve automatic line.

4. HHT

Compact design, easy to handle for manual work, easy to be integrated into robot arm for automatic work;

5. inductor (detachable | replaceable)

Canroon provided high-standard customized inductor to CR2100 induction generator, to help you deal with workpieces of different shap&size.

6. water cooling

For long service life;

7. accurate controllable heating

Local heating, controllable procedure (temperature-time, or power-time);

8. self-diagnosis

35 fault code and 11 alarm code display for faults like over current, over voltage, phase loss, short circuit, earth leakage, high temperature of heatin sink/capacitor, cooling fault, etc.

9. fault protection & logging

Fault code will display and be recorded for reference, and system will recpond with protection action like shutdown once fault occures such as open-loop or short out.

Easy for maintenance.

Model Type:

| Type | Power | Dimension | Chiller | water cooling |

| Portable Type | 10|20|30|40|50|60 KVA | 591.0*282.0*339.0 mm 621.4*282.4*349.4 mm | external |

| All-in-one Type | 10|20|30|40|50|60 KVA | 1102*668*1238.0 mm 1483*904*1363.5 mm | built-in |

| Cabinet Type | 80~800 KVA | 542*525*1250 mm 737*656*1750 mm 1080*815*1930 mm | external |

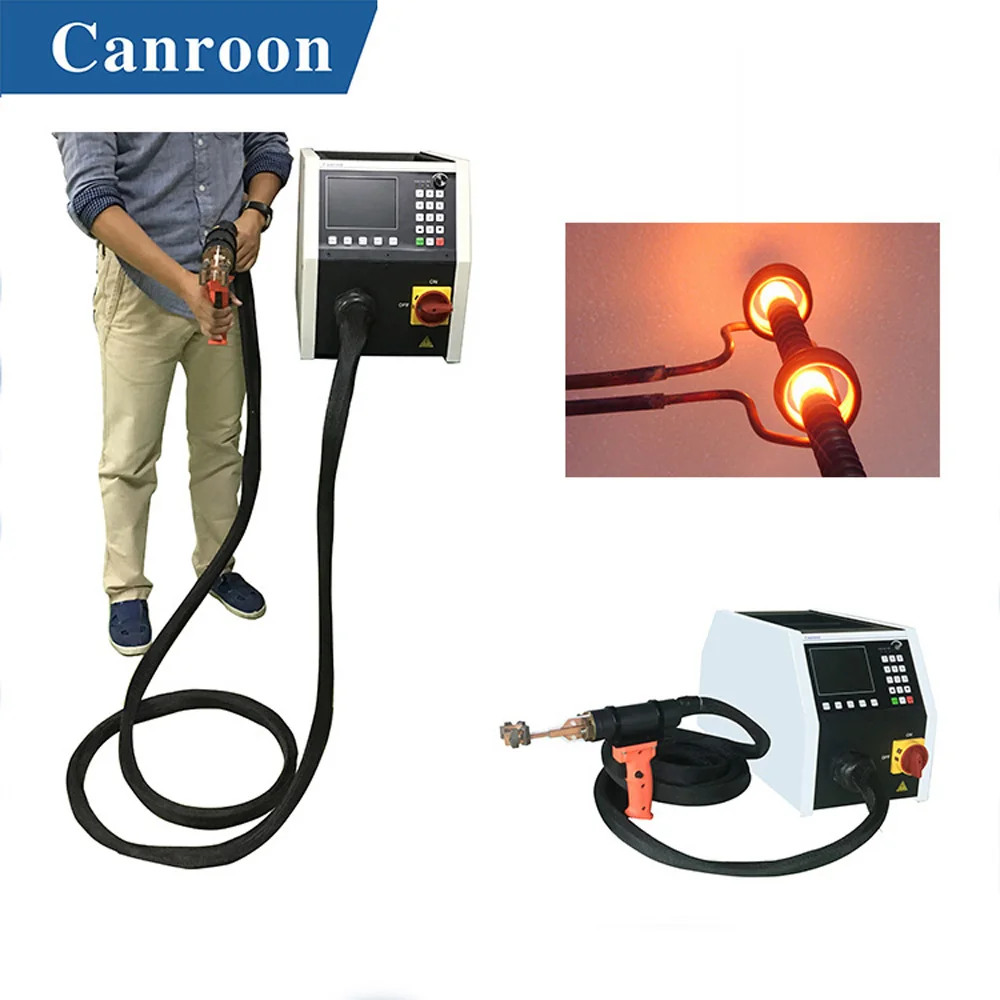

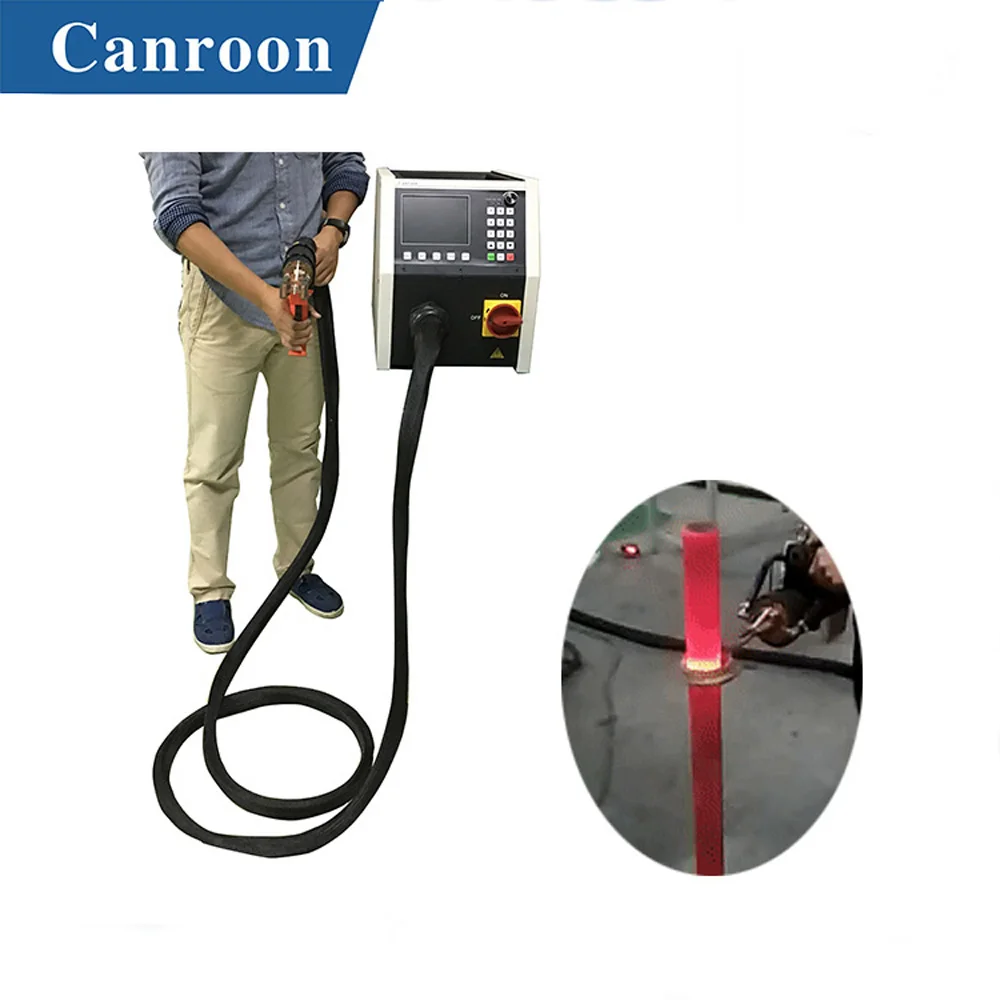

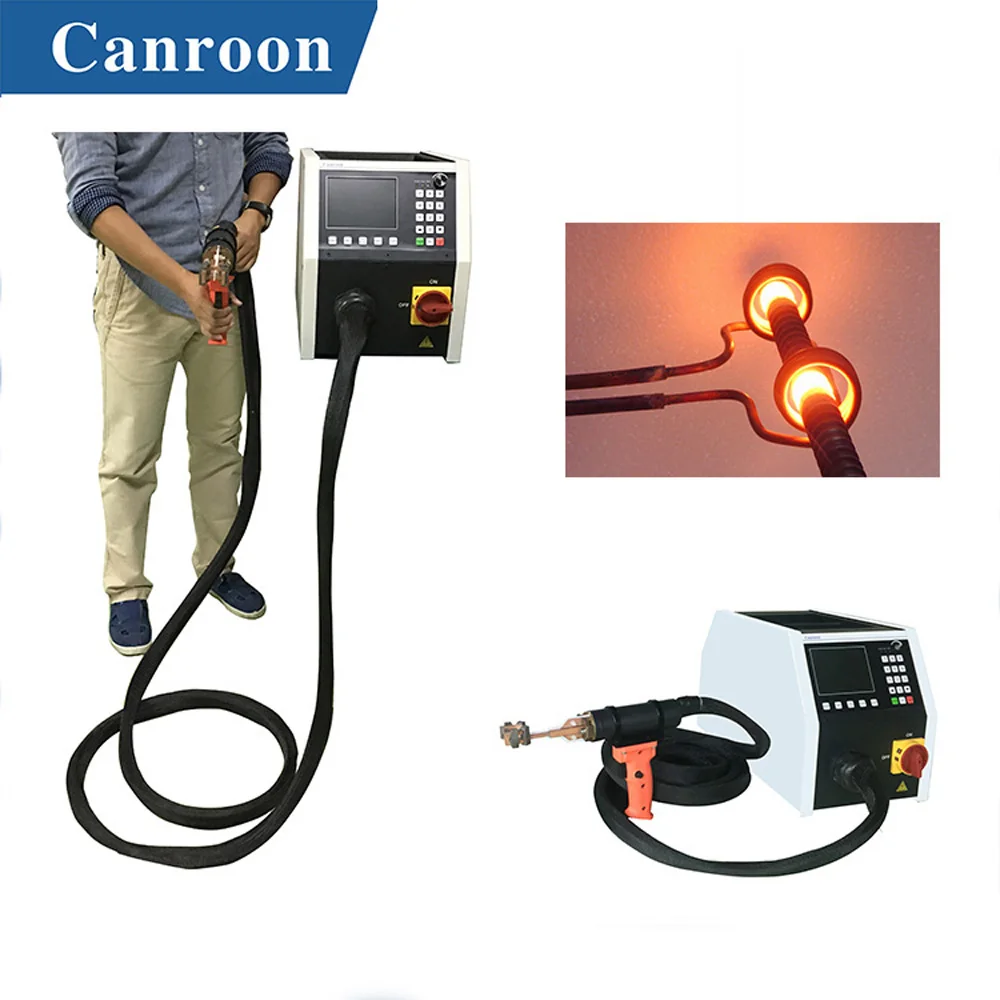

Model Pictures:

Applications:

CR2100 servies brazing job of many copper parts in motor, heating exchanger, compressor, etc

HHT (hand held transformer)&Inductors

All of our equipment is carefully packed well for safe delivery, by air, by sea, or by express according to your request.

1. keep the quality first and make more products benefit to our customers' need

2. about our Online/Sale service

1) super and solid quality

2) Fast and punctual delivery

3) Standard export package or as customers’ need.

3. After-sale service

1) Assistance to your project

2) Repairing and maintenance if any problem occur in the warranty.

3) Installation and clerks training

4) Spare and wearing parts for free or with big discount

5) Any feedback of machines can be told to us, and we will try our best to support you.

4. Other cooperation service

1) Technology knowledge share

2) Factory building advising

3) Business expansion advising

Certificates we got:

Manufacturing & Test Site:

Exhibitions we attended:

1. Are you a trading company or manufacturer?

We are a leading manufacturer of induction heating machine & VFD, located in Shenzhen, China.

2. What information should I provide when making enquiry? How to confirm the suitable equipment and solution for me?

Please provide detailed information including:

(1) application ___;

(2) workpiece: material___, dimension___, heating area___, pictures&drawing___;

(3) heating requirement: max. heating temp___, heating rate___, etc;

(4) local electricity supply for equipment running: ___V, ___Hz.

3. What's the leading time for one set, and larger quantities?

Normally we have stock of the induction heating power source, but customized inductor/coils require 15 working days.

4. What's your quality guarantee period?

12 months warranty.

5. Can I have a sample tested, and visit your factory?

We welcome you to send us sample for heating test, and will offer you test video and data.

Your visit will be highly welcomed. We will guide you through our production line, PCB & machine test procedures, burn-in room, and make heating demo for you.

6. What is your company's expect for business cooperation?

Canroon is looking forward to have a solid long-term business cooperation with you, and will offer you our continuously support in various ways.

7. What many series product do you offer in induction heating?

Canroon developed different induction heating equipment for different applications and industies.

| Power | Application | Industries |

CR2000 | 5/10/15/20/ 40/80/120KVA | Welding Preheat, PWHT, joint anti-corrosion coating | Oil & gas, on-shore & off-shore project, pipeline & power plant construction / repair |

CR2100 | 10~800KVA | Brazing / annealing / hardening / shrink fitting / straightening / curing | various |

CR210C | 30/60KVA | Coating removal | Oil&gas pipelines Storage tanks Ship/marine |

CR210D | 40KVA | Bolt untighten | High pressure turbine |

| Power | Application | Industries |

CR1000 | 40~800KVA | Forging | smelting | casting furnace | Forging | smelting | casting Crystal growth | fiber drawing |

CR1300 | 5~100KVA | pelletizer | extruder | injection molding | film blowing | dryer | Plastic machinery Chemical fiber equipment Food and drug Steam and hot air generation |

CR1400 | 12/15KVA | aluminum profile die heating | aluminum profile |

CR1500 | 6~100KVA | Heating boiler | Heating boiler |

Feel free to contact me for more information!

| Contact Sales | Sandy Liu | sales manager |

| Mob | WhatsApp| Wechat | +86 13715137235 |

| Skype | sandyliu10 |

| Tel | +86 0755-26890923 |

| Fax | +86 0755-26808681 |

| Headquarter Add. | B0926, Skyworth Innovation Valley, No.8 Tangtou 1st Road, Shiyan Street, Bao'an District, Shenzhen, China. |

| Factory Add. | 8/F, Building 8, Zhongyuntai Hi-tech Ind Zone, Songbai Road, Shiyan Street, Bao'an District, Shenzhen, China. |

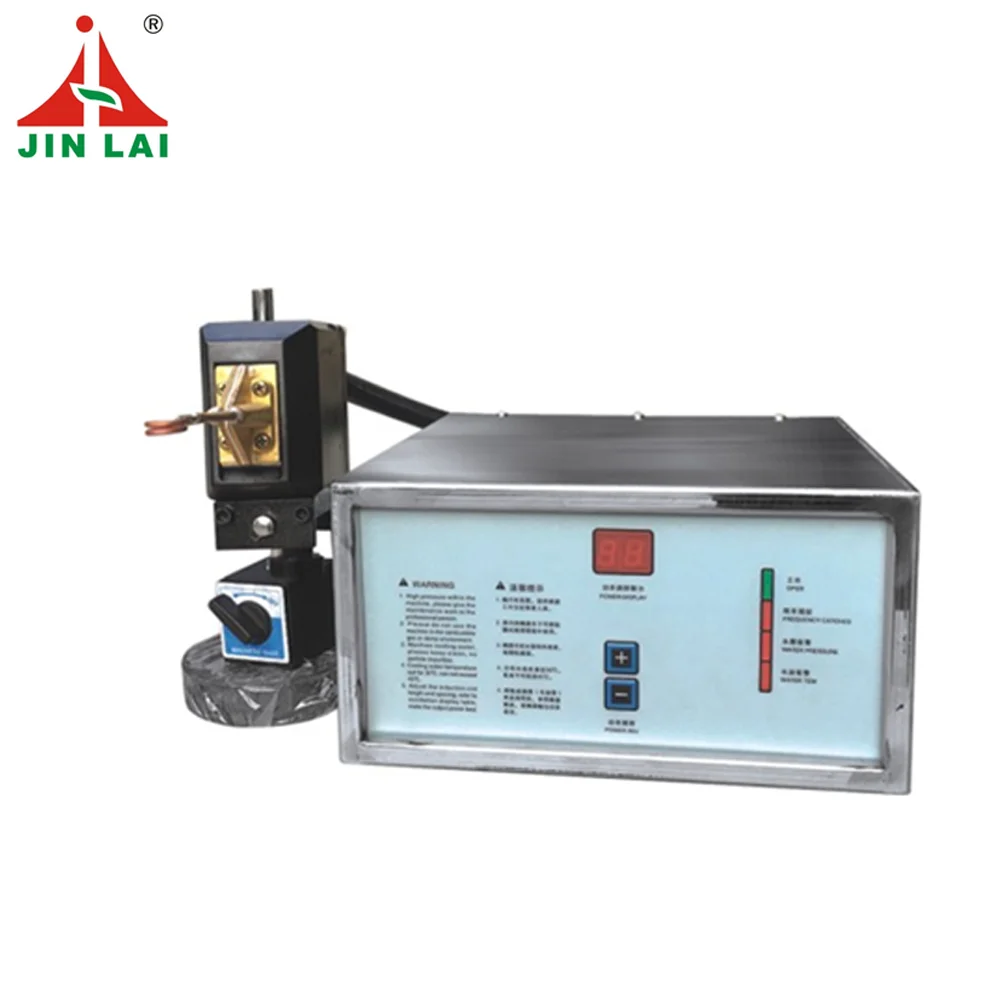

Похожие товары

Заводская цена сверхвысокочастотная паяльная сварочная индукционная нагревательная машина

Высокочастотное отопительное оборудование для сварки закалки и отжига источника питания индукционного нагрева

Сварочный аппарат цены индукционный нагревательный для металлических материалов

Хорошее качество популярный рекламный Ручной Индукционный сварочный аппарат 20 кВт

Цифровой и Портативный индукционный сварочный генератор мощностью 20 кВт для медных труб цена на нагреватель

Медь и латунь трубка пайки сварочная машина индукционного нагрева (WGH-16)

Оптовая продажа из Китая индукционный нагреватель для сварки алюминиевых/медных труб/труб припой

Новые поступления

Новинки товаров от производителей по оптовым ценам