Гибкая система впрыска протеза l Denta лабораторное оборудование

- Категория: >>>

- Поставщик: Tianjin Lizhong Huier And Technology Development Co. Ltd.

Сохранить в закладки 1600320598633:

Описание и отзывы

Характеристики

Flexible Denture Injection System l Denta Lab Equipment

| max temprature | 283 degreen |

| gross weight | 30kg |

| packing size | 34*40*57cm |

| accesory | furnace ,temprature controller, and injection frame |

Founded in 1999,tianjin,Lizhong Electronic LtD,is a manufacture or dental casting equipments with qualified engineers

and experienced workers.utility and convenience radiocaster as well as related fittings.In the same time,we are proxy

for materials from abroad such as axletrees in highspeed electric drill. With high quality

ang low price,our products are sold both in the domestic and the international markets.we are expecting the attentions

and enquiries from international indentors.

Description

The Denture Injection Unit is composed of a hot press (frame, cylinder, heater, bracket

and flask etc), and an automatic temperature control system(temperature control, timer

and electric system)

Specification

Voltage | AC220v/50HZ ±10% |

Power | 400w |

Heating temperature | 282°C-288°C |

Pressure time | 7m30s-11m |

Weight | 32kg |

Structure and working principle

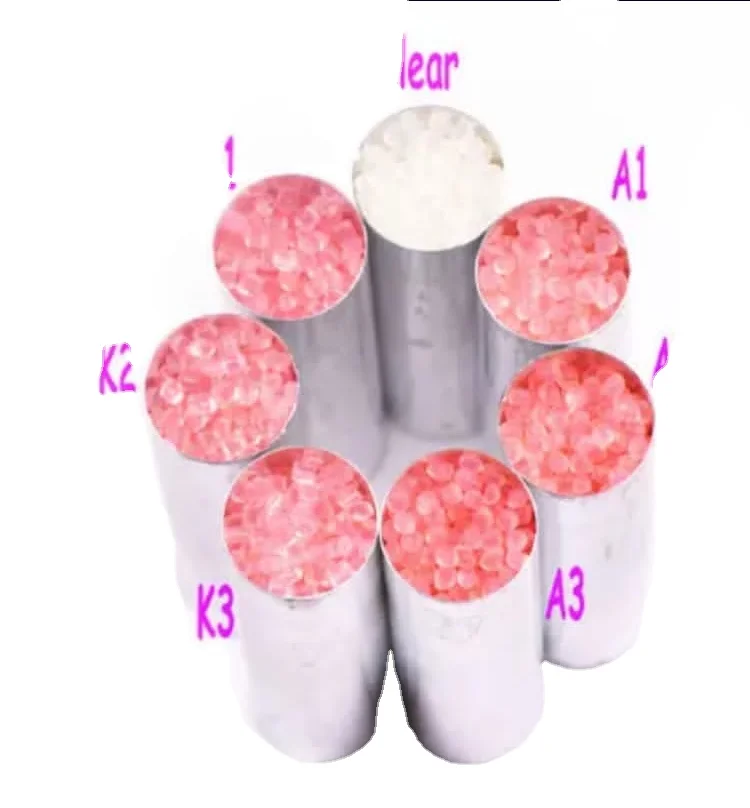

1.This injection system is composed of a heater and a hot press

2.The function of the heater is that it heats the cartridge at the temperature of the

282°-288° for about 7m30s-11m, making the flexible denture material melt in the

cartridge.

3.The function of the hot press is that it injects the molten material into flask which

is prepared in advance.

4.The heater will make a beep sound when it finishes heating.

Installations and adjustments

1.Fix the hot press to the worktable with 4bolts. The height of the table should be

convenient for operations.

2.Put the heating furnace next to hot press. The distance between the two units

should be close enough for convenient operations.

3.Before adjusting, adjust the temperature to 282° and the heating time to 7minutes

and 30s.(These are factory default)

4.Connect the plug to a power supply and turn on the power. After that turn on the

timer. The device will work normally if it the alarm is activated in the pre-time and the

fluctuation of the temperature does not exceed 10° after during the working process.

Instruction

1.Before operating, screw down the nuts of the spring on the two poles of the hot

press and put the flask on the base of the hot press.

2.First, put oil on the inner surface of the tube with a brush; then insert it into the

heater, set the temperature to 282° and heating time to 7m30s

3.Connect the heater to a power supply, preheat for at least 7m30s.It is normal for

the temperature to go 290°

4.When the temperature becomes stable (variation within 10° is considered normal).

Put oil onto the cartridge with a brush and the copper bar(put into the cartridge holder,

put in the cartridge with material fist and then the copper bar.put in the big copper bar

for medium size cartridge.put in both copper bars for small size cartridges)

5.After the cartridge is put inside the heater, turn on the timer and after 7m30s it will

make a beep sound. User can take out the cartridge to put it on the hot press for injection.

Then remove the cartridge 2minutes after the injection.

Safety protection device and cautions

1.This machine has a grounding protection. Make sure it is grounded while using.

2.After the injection, there might be some material left in the cartridge holder, which can

be pushed out by the hot press. If not, users can start the heater for easier removal.

Maintenance and post-sale service

1.The power should be turned off if the machine will not be used for a long period. Clean

up the remains and dust to avoid malfunction.

2.The main frame is given 1-year warranty; the heating loop, temperature controller and

time controller for three months.

Troubleshooting

Похожие товары

Электрическая машина рикша педикаб тук для

Жареные орехи кешью фруктовый смешанный

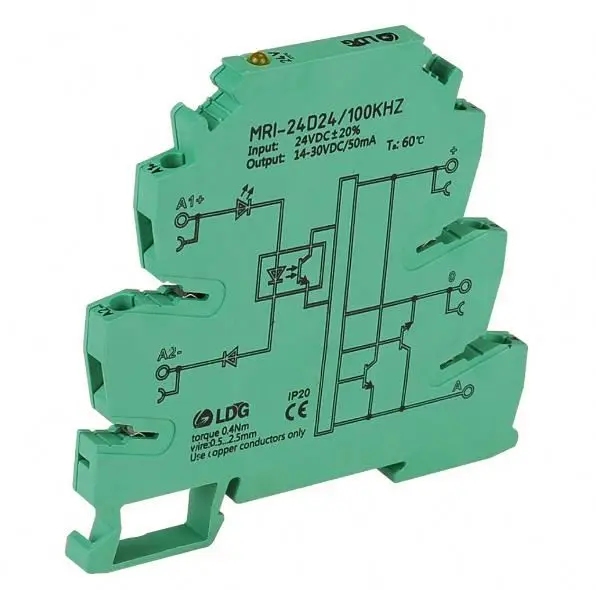

MRI-24D24 100 кГц высокой частоты оптрон релейный 24VDC 8mA с входом и выходом 14-30VDC 50mA интерфейс напряжения релейный модуль DIN Rail

G6Y-1 5VDC High-frequency Relay

CoolSize ручка для входной двери и одноцилиндровый замок с заглушкой ключ набор тонких квадратных ручных блокировочных

Гипохлорит кальция, мин. 65%, Hipoklorit kalsium

Твердый Гипохлорит натрия, промышленная очистка сточных вод, очистка сточных вод, дезодорант, дезинфекция, антиводорослей

Новые поступления

Новинки товаров от производителей по оптовым ценам