Прецизионная металлическая потолочная плитка перфорация производственная линия Перфорированный потолок гидравлический пресс машина заводская цена

- Категория: >>>

- Поставщик: Guangzhou Kingreal Machinery Co. Ltd.

Сохранить в закладки 1600323781325:

Описание и отзывы

Характеристики

Products Description

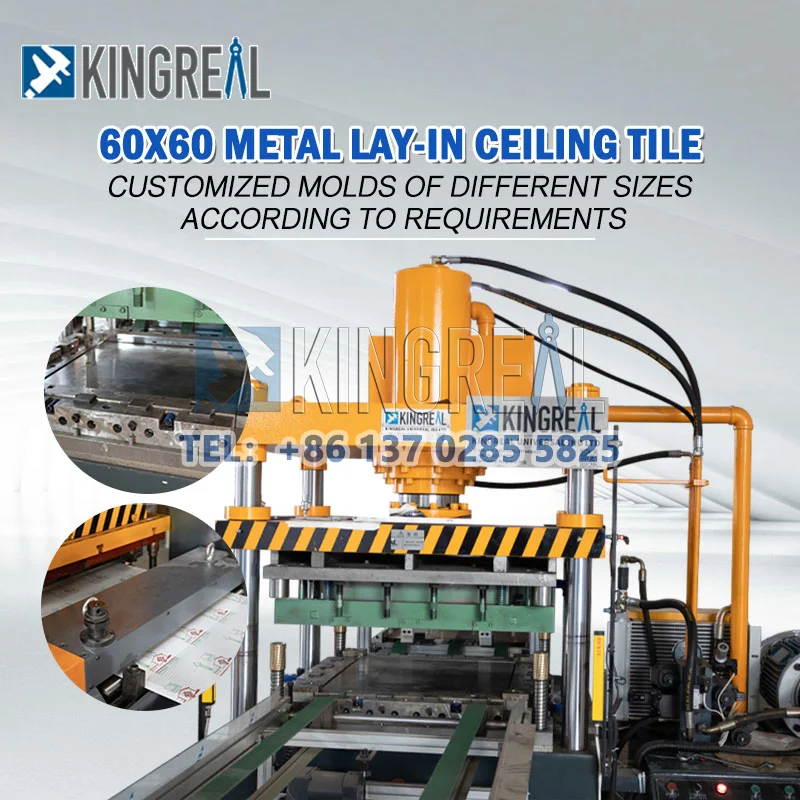

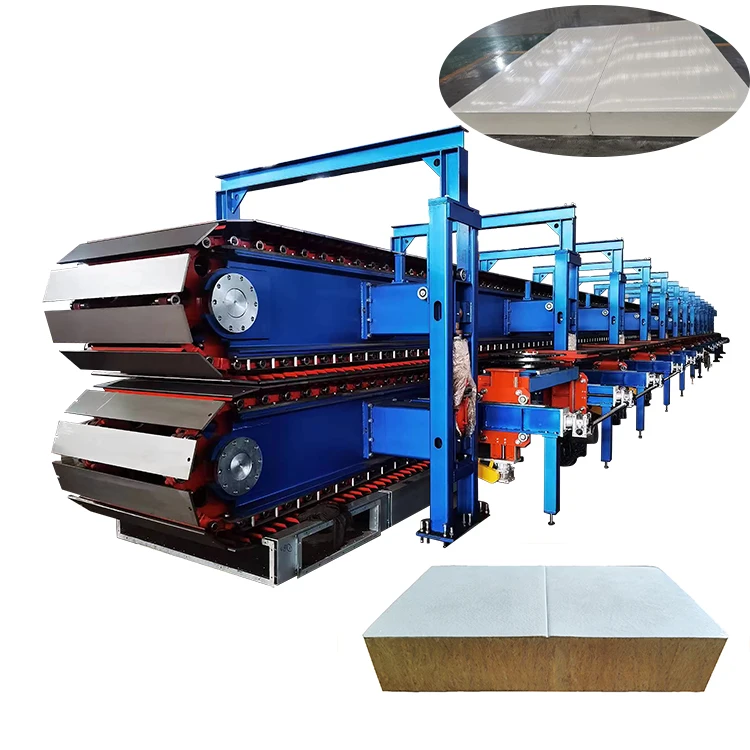

Metal Perforated Ceiling Tile Perforation Production Line Machine

KINGREAL suspended metal ceiling production line can do the steel ceiling sheet perforation and aluminum ceiling sheet perforation on the same line. And we use high speed gantry press the speed is up to 200SPM.

For the metal ceiling perforation holes are very important which can reduce the noise and more beautiful appearance. Most popular perforation size on markets including 1.8mm diameter holes, 2.5mm diameter holes, 1.0mm diameter holes. There are also different align method including straight align and stagger align. All these different sizes of perforation holes need to be produced by different perforation mold.

Technical parameter :

Des. | Specification | ||||||

Product Name | Suspended metal ceiling tiles | ||||||

Products Type | CLIP IN, LAY IN, LAY ON, Tegular tiles, Access panel, etc | ||||||

Products Size | 600*600MM, 300*300MM, 600*1200MM, 300*1200MM, 450*450MM, etc | ||||||

Production Line Type | Full automatic, including auto perforation, auto notching, auto turn, auto bending forming | ||||||

Production Speed | 0-10PCS/min according with different perforation styles | ||||||

Machine Type | Full automatic production or semi-automatic production | ||||||

Machine Power | ~ 40 KW | ||||||

Metal Ceiling Tile Punching Detail Display

Structure including : | ||||||||

- Decoiler | ||||||||

- Punch press & servo feeder | ||||||||

- Main roll forming machine | ||||||||

- Auto shearing station | ||||||||

- Output table | ||||||||

- Electrical& hydraulic system | ||||||||

KINGREAL Product Quality Control

Application

Certifications

Our products have passed the international ISO9001 and European CE certification,

and being exported to many European countries.

Related products

Company Profile

KINGREAL UNIVERSAL INDUSTRIAL LIMITED is established on 1995 and is dedicated on researching, desgin and metal ceiling production factory manufacturing all kinds of metal ceiling perforation production line, HVAC Duct Auto Manufacture Line, T bar roll forming machine, metal slitting line, cut to length line, acoustical ceiling tile textile install machine, cold roll forming machine and etc.

Our machinery and production line had been exported to Turkey, Saudi, UAE, Russia, etc and win good reputation all around the world.We warmly welcome old and new customers from all over the world to visit our company and establish business relationships with us. We do believe our mutual cooperation will create a brilliant future.

Our machinery and production line had been exported to Turkey, Saudi, UAE, Russia, etc and win good reputation all around the world.We warmly welcome old and new customers from all over the world to visit our company and establish business relationships with us. We do believe our mutual cooperation will create a brilliant future.

Product packaging

For different machines or production line parts, we have different packing solutions:

* For the machine or production line, using plastic film to cover and wrap. Then will be loaded to the container by forklift or crane.

* For the key parts such as the roll forming rollers set, we will use the metal frame to package.

* For the electrical cabinets, molds set, we will use wooden carton to package and load.

* For the electrical cabinets, molds set, we will use wooden carton to package and load.

FAQ

Q1. Are you a manufacturer?

A1. Yes, KINGREAL Machinery is a professional sheet metal processing machines manufacturer, we are an OEM.

We have been focusing on the field of machine manufacturing for more than 20 years.

A1. Yes, KINGREAL Machinery is a professional sheet metal processing machines manufacturer, we are an OEM.

We have been focusing on the field of machine manufacturing for more than 20 years.

Q2. How to visit your factory?

A2. There are 2 ways: either by plane or by train to Foshan/Guangzhou port. We will be picking you up in plane/train station, then we can go together.

A2. There are 2 ways: either by plane or by train to Foshan/Guangzhou port. We will be picking you up in plane/train station, then we can go together.

Q3. What's your delivery Time ?

A3.Within 60-80 days after receiving prepayment. Some machines in stock, can be delivered at any time.

A3.Within 60-80 days after receiving prepayment. Some machines in stock, can be delivered at any time.

Q4.Do you provide after-sales service?

We provide 24-hour online service for our customers.

A4. We will debug the machines freely in our factory make sure everything is OK before shipment.

When engineer go to your place to debug the machines, all according expense shall be paid by you.

We provide 24-hour online service for our customers.

A4. We will debug the machines freely in our factory make sure everything is OK before shipment.

When engineer go to your place to debug the machines, all according expense shall be paid by you.

Q5. What can you do if the machine breaks down?

A5. We will include some spare parts with the machine itself, if emergency we will send required parts by air to ensure problem solved quickly.

A5. We will include some spare parts with the machine itself, if emergency we will send required parts by air to ensure problem solved quickly.

Q6. Can you ensure the safety of the machine during transportation?

A6. Yes we can, we use iron wire for fixing machines in container, also small wood pads to hold machines tight and don't move around during shipment.

A6. Yes we can, we use iron wire for fixing machines in container, also small wood pads to hold machines tight and don't move around during shipment.

Похожие товары

Австралия популярные разные размеры 100-600 мм ширина регулируемый перфорированный Электрический канальный кабельный лоток формовочная машина

9 850 987,55 ₽ - 10 456 355,50 ₽

Автоматическая машина для производства гвоздей по Заводской Цене штукатурка гипсовый карниз производственная линия

2 828 651,25 ₽ - 3 216 897,50 ₽

Высокопроизводительные автоматические машины для изготовления гвоздей из нержавеющей стали промышленности

924 561,96 ₽ - 990 602,10 ₽

Эффективная машина для передачи кабеля крупномасштабных телекоммуникационных проектов

94 288,38 ₽ - 97 616,20 ₽

Низкая цена оптический кабельный трактор: повышение скорости и точности прокладки кабеля

94 288,38 ₽ - 97 616,20 ₽

Бесплатная доставка Высокопроизводительный провод и кабельный конвейер для промышленного управления кабелем

93 556,87 ₽ - 96 858,88 ₽

Машина для производства сэндвич-панелей

16 510 035,00 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

Hantek щупы осциллографа автоматический Тестовый Кабель Ht30a Bnc к банану двойная Банановая головка многоцелевое автомобильное

3,10-3,44 $

Горячая распродажа ручная работа традиционная деревянная урна для домашних животных квадратная коробка золы собак и кошек персонализированная Лучшая цена

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $

Irdmco экологически чистый минималистичный прямоугольный деревянный ящик для хранения стеллаж поделок и детских игрушек Домашняя мебель гостиной

Технология сенсорных перчаток и аксессуары для детей от дождя холода M725132-334

1,07-1,40 $

GY6 6 Pin AC гоночный CDI для CG125 CG250 двигателя Dirt Pit Bike ATV Quad

Парик из синтетического волокна для косплея

9,85-12,66 $

Прямая Продажа с фабрики 65 см Модернизированный подвесный стерео голографический проектор светодиодный вентилятор высокой четкости экран 3D дисплей

155-185 $