Вращающаяся сушилка с тремя барабанами оборудование для сушки летающей золы вращающаяся цена

- Категория: >>>

- Поставщик: Gongyi Derui Machinery Co. Ltd.

Сохранить в закладки 1600325356036:

Описание и отзывы

Характеристики

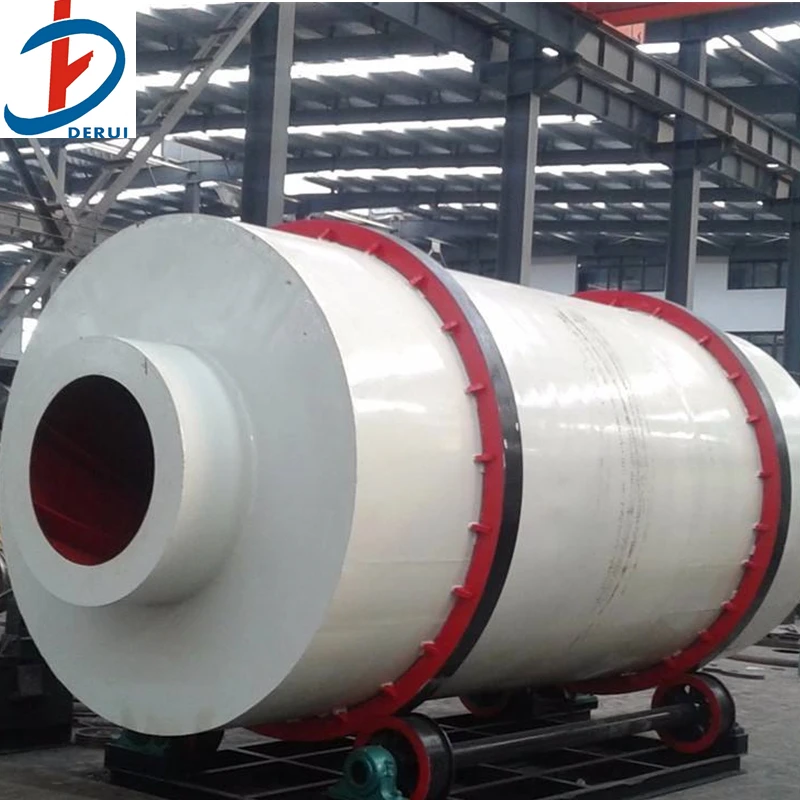

Three Drum Rotary Dryer For Fly Ash

The three-cylinder dryer is an improved energy-saving product based on the single-cylinder rotary dryer. It has been recognized by many industries and has achieved good results. This equipment increases the pre-drying design of the wet material before entering the machine and prolongs the drying time of the wet material in the machine, and installs sealing, heat preservation and reasonable supporting measure. So the efficiency of the dryer's production capacity is greatly improved. The advanced technology, reasonable operating parameters and easy operation, make it widely used in the drying process of sand, slag and other mixed materials from various industries. The material exchanges heat between the inner cylinder and the hot air flow in the form of radiation, convection, and conduction, and the heat exchange in the outer cylinder is combined with conduction and convection. Therefore, the thermal efficiency is high and the energy saving effect is significant. Moreover, the importance is the outlet temperature of this dryer is low, which helps to extend the service life of the tail dust removal system.

Scope of application: iron powder, mineral powder and other mixed materials, dry-mixed mortar, yellow sand in the construction industry, and raw materials in the chemical, foundry and other industries.

In addition, fuel burners, combustion chambers or supporting elevators, belt conveyors, metering feeders, cyclones, pulse dust collectors and spray towers can be designed according to user needs.

1. With high technical design of self-insulation of the cylinder, the thermal efficiency is as high as 70% (the thermal efficiency of the single-cylinder dryer is only 35%), which saves 68% of coal than the single-cylinder dryer.

2. The length of the three-cylinder dryer is 60% shorter than that of the single-cylinder dryer, reducing the building area of the plant.

3. It adopts heat-resistant abrasion-resistant alloy steel plate, which is 4 times more wear-resistant than ordinary steel plate. Long service life and easy maintenance.

4. High thermal efficiency, the temperature of the outer cylinder is lower than 60℃ (the temperature of the outer cylinder of the single cylinder dryer is as high as 150℃), and the outlet temperature is lower than 60℃.

5. The outlet temperature is low, which is conducive to the long use time of the dust removal equipment. It can be directly matched with the pulse bag filter.

6. Supporting wheels are used for rotation to replace the large and small gears. Stable operation.

7. The fuel can be adapted to coal, oil and gas.

The main body of the three-cylinder dryer drives the four transmission rollers at both ends through four reduction motors, so that the tire belt rotates around the center. When the wet material enters the feeding end of the dryer through the feeding device, and the wet material is quickly pushed to the spiral lifting plate through the spiral guide plate. With the rotation of the cylinder, the spiral lifting plate installed in the three cylinders makes the material continuously lifting, rolling, throwing, scattering, and moving towards the discharge end at the same time. Meanwhile, the hot air from the hot blast stove enters the inner cylinder, the middle cylinder, and the outer cylinder in sequence to conduct intense heat exchange with the material. After the material and hot air flow are zigzag reciprocating in the three layers of cylinders, the heat energy is fully utilized to achieve the drying effect and materials are discharged.

1. Before sales, we sales team will know know the real situaiton from our customers, such as the feeding size, crushing capacity, final sizes and the electricity condition,etc. then our technician team will design proposals according the situations, and we will update the solution according to customer's further requirements.

2. After concluding the contract, our engineer technician will prepare the foundation drawing about the equipemnts. at the same time, our production factory will prepare the equipment timely.

3. After delivery, our installation engineer will be ready to guide the installation and commissioning for the equipment, to make sure that each item going smoothly and meet the customer's requirements.

Our Company Philosophy

- Best Quality for Market

- Perfect Service for Clients

- Scientific Management for Benefits

- Good Credit for Development

Gongyi Derui Machinery Co., LTD entered the mechanical industry from the beginning of the 1980’s, earlier than most factories. With the company philosophy these years, our products are sold to many customers from home and abroad, popular in India, Russia, Kazakhstan, Africa, South America, Mid-East, Southeast Asia, and almost 30 countries and areas. And it is our honor to make a contribution of to the development of these countries.

Growth is only a process, and the brilliance is the new beginning. In order to respond positively to the good policy of The Belt and Road, we will, as always, provide higher and higher quality products and service, to win more and more acclamation and respect for Chinese national industry. Review ourselves with serious attitude, and win the trust with excellent quality. We sincerely hope to take win-win cooperation with entrepreneurs and companies all over the world, to develop the market together.

Похожие товары

Высококачественный жесткий диск TXRUI 2,5 дюйма SSD SATA 3 60 Гб SATA III

Прокладка крышки масляного насоса Sea-Doo Spark 420431840 2014-2018

Створчатое крепление безопасности полумесяц оконный створчатый замок с латунным покрытием

Huawei EG8141A5 XPON Gpon ONU 1GE + 3FE + 1 конвейер + USB + WIFI 5dBi беспроводной маршрутизатор ONT модем терминал De Fibr Optical

Искусственная трава, резиновые заполняющие гранулы, синтетическое напольное покрытие для бадминтона, цена крошечной резины

Автоматический шовный степлер covidian GIA

Китайский продукт с хорошей портативной идеальной звуковой системой OEM & ODM A10, Активный монитор сабвуфер

Новые поступления

Новинки товаров от производителей по оптовым ценам