Горячая Распродажа высококачественный сверлильный станок Dk7750az Edm Cnc для резки проволоки

- Категория: >>>

- Поставщик: Jiangsu Sanxing Machinery Manufacture Co. Ltd.

Сохранить в закладки 1600327911148:

Описание и отзывы

Характеристики

| Type | Unit | DK7750AZ |

| Worktable size | mm | 820*556 |

| Table travel | mm | 630*500 |

| Max. workpiece thickness | mm | 500 (400) |

| Total weight | kg | 2500 |

| Overall dimensions | mm | 1870*1590*1660 |

| Wire traveling speed | m/s | 11.5 |

| Wire diameter | mm | 0.13~0.18 |

| Max. cutting speed | mm²/min | 100 |

| Taper | º/mm | 6º/100 |

| Power input | 3N-50Hz 380V (Monophase 50Hz 220V) | |

| Total power | KW | ≤1.2 |

Features:

1.High cutting speed up to 100mm2/min or more .

2.Four axes X,Y,U,V work.

3.Work pieces to 1000mm thick.

4.Taper angles up to ± 30°. Standard is equipped with ± 6° taper.

5.Molybdenum wire diameter 0.18 mm (optional).

6.Accuracy: 0.015mm,0.01mm, even 0.008mm.

7.Roughness: Ra 1.0-2.5 µm.

8.Wire speed adjustable 5m/s~11.5m/s.

9.High precision ball screw.

10.Stable and durable.

| Advantages of Vertical Incorporate Controller | |

| 1, High intelligent grape exchange software system; |

| 2, Graphically programming and vector programming; | |

| 3, 3B, G codes compatible, communicating with microprocessor; | |

| 4, DXF, AUTOP graphic document, CAD character library document; | |

| 5, Hard disk with big processing and storage capacity; | |

| 6, Return, retreat and stop functions for graphing ordinary curves; | |

| 7, Simultaneous indication of processing tracks and data, power-off memory function; | |

| 8, Interaction of four shafts, processing special shaped surfaces; | |

| 9, Parallel work, inputting program while processing; | |

HL, HF, AutoCut

| 1. Windows 98/Windows XP; |

| 2. Industrial computer; |

| 3. Auto CAD file can be transferred into working; |

| 4. Return, retreat and stop functions; |

| 5. Simultaneous indication of processing tracks and data, power-off memory function; |

| 6. Interaction of four shafts, processing special shaped surfaces; |

| 7. Parallel work, inputting program while processing. |

Optional

| 1. Taper (± 15°, ± 30°); |

| 2. Linear guide ABBA; |

| 3. Servo motor; |

| 4. High pressure pump; |

| 5. DRO digital read out is optional, accuracy of 0.005mm; |

| 6. Environmental and protection cover; |

| 7. Higher speed control , speed up to 160 mm²/min ; |

| 8. Multi-cut function to reach better accuracy and surface roughness; |

| 9. Thickness up to 1000mm; |

| 10. Color. |

Jiangsu Sanxing Machinery Manufacture Co.,Itd was founded in 1993. The company is a high-tech enterprise integrating research and development, production and sales. Our company has been awarded IS09001-2008 international quality certificate CE certificated for Europe, and also honored with "enterprise of high-tech". Our many products are titled “high-tech products” and “provincial famous trademark”, get the Machinery Industrial Science And Technology Award and the Small & Medium Enterprises Innovation Award of the Ministry of Science and Technology, meanwhile, the products own 3 invention patents, 27 New practical patents, 3 designing patents and 7 patents during application. |

| ♦ Packaging details: inner plastic, outer plywood case |

| ♦ Delivery detail: 15-20 days afterpayment |

| Minimum order quality: 1 set |

Port: Shanghai or any Chinese port |

| Payment Method: L/C, T/T, Western Union, MoneyGram |

| Supply Ability: 200 sets/month |

| 1. Could we use our own brand on your machine ? |

| Yes, we would love to accept. |

| 2. Could your engineers go to our factory to install the machine and train our workers? |

| Yes, our engineers could go to your factory and assist you. |

| 3. Can your company change the control system according our requirement ? |

| CNC system is optional. |

New address: The West of Chunfeng Road, TaiZhou City, JiangSu Province, China

Tel: 0523 86820221 / 0523 86820285

Fax: 0086 523 86820388

Web:

Skype:sharonljm / merry13080206

Tel:+86 18115232326

Whatsapp :008613775704627

Похожие товары

Отбеливающее мыло OTVENA из козьего молока, натуральное и органическое мыло ручной работы для очистки лица

Jmen 12785021 газовая пружина для SAAB 9-3 03-11 капот амортизационная стойка подъемник

Для домашнего использования Lastek холодный лазер вагинит инфракрасная световая терапия для женщин Тазовая инфекция медицинское оборудование

KLHS полипропиленовая линия по производству полой сетки/полипропиленовая машина для производства полой сетки

Оптовая продажа, высококачественные современные круглые Настенные часы, декоративные большие круглые Настенные часы для украшения дома

Керамический сотовый фильтр кордиеритовая катализационная Подложка для каталитических конвертеров разного размера 400 CPSI

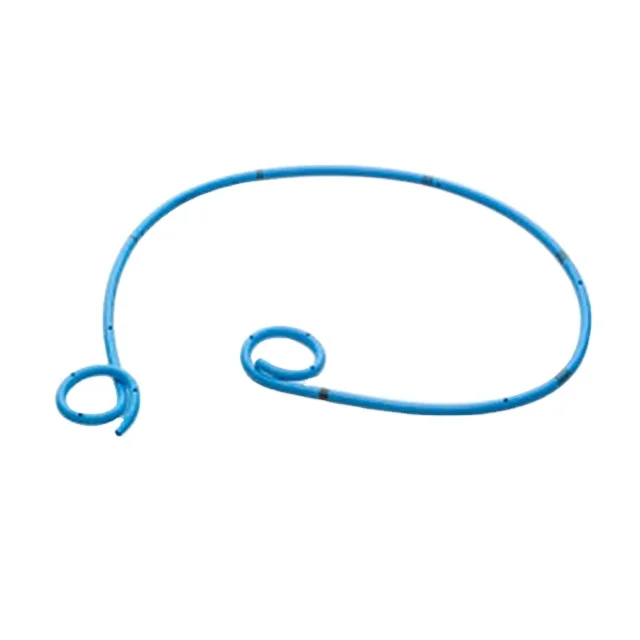

Урологический катетер двойной J Pigtail

Новые поступления

Новинки товаров от производителей по оптовым ценам