Горячая Распродажа 6yl 30 68 мини масло для использования на растении авокадо арахис хлопковые семена кокосовое пальмовое пресс машина линия с винтовыми запасными частями

- Категория: >>>

- Поставщик: Zhengzhou Etornuo Machinery Co. Ltd.Zhengzhou Ltd.

Сохранить в закладки 1600329256672:

Описание и отзывы

Характеристики

Hot Selling 6yl 30 68 Mini Oil Plant Use Avocado Peanut Cottonseed Coconut Palm Oil Press Machine Line With Screw Spare Parts

Structure of Oil Press Machine Line:

a.Characteried by simple design, easy to operate and maintenance

b.Cast iron machine base

c.High productivity,energy saving and labour saving

d.Special gear box structure make the rotating speed averagely

e.Compact structure, stable functions

f.Main parts of chamber through the processing of high-temperature tempering and low temperature quenching;

g.Compact structure, stable function.

Click Now for Detailed Video and Quotation Sheet

Introduction of Oil Press Machine Line:

1. Working Principle

When the raw materials have been sent to the hopper of oil press machine and then been moved forward by the rotating pressing screw for pressing. Under the high-pressure condition in the chamber, friction between material and screw, chamber will be created, which also creates friction and relative movement among material particles. On the other hand, root diameter of the pressing screw caries larger from one end to the other, hence. When rotating, it not only pushes particles to move forward,but also turns them outwards as well. Meanwhile,particles adjacent the scew will rotate along with screw‘s rotating, causing every particle inside the chamber to possess different speed. Therefore, relative movement among particle creates heat which is necessary during manufacturing becasue of helping protein change property,damage colloid,increase plasticity, decrease oil’s elasticity, resulting in high oil productivity.

2. Wide Application

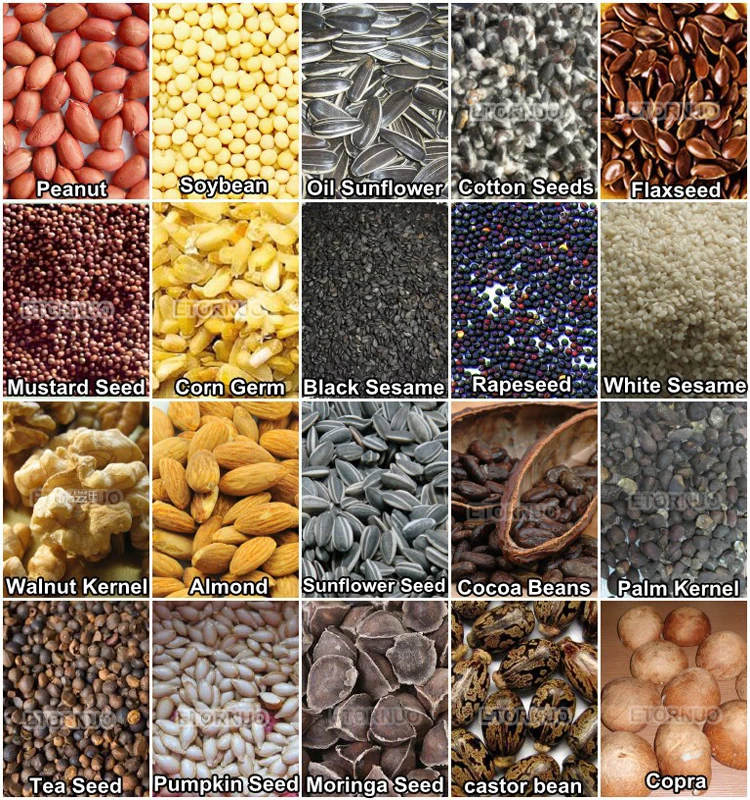

The screw type oil press machine line has wide application, which can be applied to many kinds of oil crops such as the peanuts,sunflower seeds,ricino,coconut, almond, canola seed,walnut, copra,palm kernels, rapeseed, flaxseed,coconut, cotton seeds, sesame,soybeans,flax seed,etc.

3. High Oil Yield And Low Dry Cake Residual Oil Rate

The oil press machine line produces clear oil and superior grade oil cake with about 6% residual oil rate.

4. Durable Spare Parts,Gears,Heating Tube and Motor

1. Full-Automatic Oil Press Machine Line

Model | Power | Capacity | Packing Size | Gross Weight |

ETOOP68A | 5.5 KW | 50-60KG/H | 1250x850x1400MM | 350KG |

ETOOP68AA | 5.5 KW | 50-60KG/H | 1450x850x1400MM | 380KG |

ETOOP80A | 5.5 KW | 110-130KG/H | 1850x950x1650MM | 690KG |

ETOOP95CA | 7.5 KW | 200-220KG/H | 1900x990x1750MM | 900KG |

ETOOP100A | 7.5 KW | 200-220KG/H | 1900x990x1750MM | 900KG |

ETOOP120A | 11 KW | 250-300KG/H | 2100x1100x1750MM | 1030KG |

ETOOP120CA | 15 KW | 300-350KG/H | 2250x1100x1850MM | 1180KG |

ETOOP130A | 18.5 KW | 450-500KG/H | 2500x1200x1900MM | 1260KG |

ETOOP160A | 22 KW | 750-800KG/H | 2550x1300x1950MM | 1560KG |

2. Semi-Automatic Oil Press Machine Line

Model | Power | Capacity | Packing Size | Gross Weight |

ETOOP68 | 5.5 KW | 50-60KG/H | 880x480x660MM | 200KG |

ETOOP68C | 5.5 KW | 50-60KG/H | 880x480x660MM | 200KG |

ETOOP80 | 5.5 KW | 110-130KG/H | 1750x550x700MM | 380KG |

ETOOP95C | 7.5 KW | 200-220KG/H | 2100x610x760MM | 550KG |

ETOOP100 | 7.5 KW | 200-220KG/H | 2100x610x760MM | 550KG |

ETOOP120 | 11 KW | 250-300KG/H | 2200x610x770MM | 660KG |

ETOOP120C | 15 KW | 300-350KG/H | 2250x700x770MM | 720KG |

ETOOP130 | 18.5 KW | 450-500KG/H | 2350x700x770MM | 1000KG |

ETOOP160 | 22 KW | 750-800KG/H | 2500x700x770MM | 1200KG |

3. Crude Oil Refinery Equipment

The purpose of refining the crude oil is to remove free fatty acids,phospholipids, pigments, off-flavor, and other impurities. The whole oil refining line includes Degumming / Neutralization, Bleaching, Deoderization, and Winterization(optional).

a.Neutralization pot: For acid refining, alkali refining and water washing.

b.Decolorization pot: Bleach oil and remove pigment from oil.

c.Deodorization pot: Removing odor from oil (Made of 304 stainless steel).

d.Transfer oil furnace: Providing heat energy for production,the temperature can reach 280°C.

e.Vacuum pump: Provide vacuum degree for decolorization,deodorization,up to above 755mgHg.

f.Air compressor: Dry decolorization bleaching clay.

g.Filter press: Filter bleaching clay.

h.Steam generator: Provide steam for deodorization & distillation.

This system belongs to batch type refining, the capacity could be 1~20Ton per day.It not only refines the salad oil, high cooking oil, first grade oil and second grade oil, but also refine animal oil, such as the lard oil, fish oil. it's the idea choice of Medium and small scale oil refinery plant.

4. Oil Production Line

The whole oil press machine line consists of vibration cleaning sieve, roasting machine, screw conveyor, oil press machine, frame oil filter, oil refinery equipment and oil filling machine.

Packing Materials

1.The oil press machine line will be sent to you by sea, by air or by international express according to the volume and weight of cargo.

The whole oil production lines have been installed on Benin, Botswana, Congo, Cameroon, Ethiopia, Ghana, Kenya, Mali, Nigeria, Sudan, Tanzania, South Africa, Zambia, Zimbabwe, etc.

1.Quality warranty period is two years (except the wearing parts).Equipment must be 100% brand new when leaving factory. Malfunctions which are caused by machine-self and quality will be responsible for our manufacturer.

2. Whole lifetime maintenance free of charges.

3. Free training course at our plant.

4.Free technical support online or by phone communications&emails.

5.Our engineer can be assigned to your country for testing and training as per your requirement.

Q1:What’s the payment terms?

A1:T/T,Trade Assurance,Western Union, MoneyGram,L/C, Cash etc.

Q2:What kind of seeds that the machine can press?

A2:The oil press machine line can press the peanuts,sunflower,ricino,coconut, almond, canola seed,walnut, copra,palm kernels, rapeseed, flaxseed,coconut, cotton seeds, sesame,soybeans,flax seed,etc.

Q3:What about the warranty?

A3:Quality warranty period for this machine is one year. Malfunctions which are caused by machine-self and quality will be responsible for supplier. The spare parts will be sent to you free of charge.

Zhengzhou Etornuo Machinery Co., Ltd. is the professional exporter of mechanical equipment in China.It is noted for professional testing center; reliable after-sale service and quality control system.

Zhengzhou Etornuo Machinery Co., Ltd. is engaged in agricultural machinery research and development, production and trade. Our main products are oil seeds processing machines such as vibration cleaning sieve, copra chopper, hammer mill, roasting machine, screw conveyor, oil press machine, frame oil filter, oil refinery equipment and oil filling machine, etc.

Our products are not only very popular in domestic market, but also are exported to Southeast Asia, the Middle East, Europe, South and North America and Africa. As a pioneer in this field, we have accumulated plenty of experience in all aspects of production, sale, and service of machinery. If you are interested in any of our products, please feel free to contact us for further information. We sincerely welcome customers from both at home and abroad to cooperate with us to develop friendly and mutually beneficial business relationships.

Похожие товары

Небольшая мини-машина для приготовления сырого масла подсолнечника соевого хлопка растительного

Лидер продаж машина для прессования кунжутного масла извлечения растительного цена

Китайский завод промышленный гидравлический пресс для орехового ореха 50 тонн продажи

Низкая цена Дистилляция эфирных масел для дома малобюджетная промышленная дистиллятор продажа

Катушка подачи ccd сортировщик кукурузного масла делая машину для завода по переработке пальмы с нефтеперерабатывающим заводом

Дизельная машина для обработки пальмового масла дробилка зерен пальмы

Электрический Масляный Пресс 820 Вт Автоматический бытовой коммерческий из нержавеющей стали

Новые поступления

Новинки товаров от производителей по оптовым ценам