Горячая продажа консольная дуговая сварочная коробка для дуговой сварки

- Категория: Other Construction Material Making Machinery >>>

- Поставщик: Wuxi Zhouxiang Complete Set Of Welding Equipment Co. Ltd.Wuxi Ltd.

Сохранить в закладки 1600329399776:

Описание и отзывы

Характеристики

Cantilever submerge arc welding machine

Cantilever submerged arc welding machine and cantilever back welding machine have the same structure: moving cart, stand column, transverse boom, welding arm, seam tracking device, wire feeding system, and electric control box. Their only difference is the configuration of welding power.

1. Two sets of motors drive four wheel axles through the gear. It composes 4 wheel driving systems, in order to make it stable and reliable operation. On the base of a double-decker frame, you can put welding power on bottom and wire plate or wire tube on top.

2. The stand column’s structure size is big, so it can improve its rigidity. Electric cabinet and operating panel are inside the stand column. Operators can control it on cart.

3. Main body of upper beam is square pipe, which is light and has high rigidity. There are guiding rail and rack on upper beam. It makes tool carriage and transverse arm moving horizontally on the beam.

4. The welding power can be single arc single wire or double arc double wire:

1) Single arc single wire can use Zhouxiang ZX5-1000 submerged arc welding power or America Lincoln DC-1000 submerged arc welding power;

2) Double arc double wire usually uses America Lincoln DC-1000(direct-current), AC-1200 (alternating current) submerged arc welding power.

Suitable work-piece size | 300-1200mm |

Welding speed | 0.3-1.5m/min |

Feed and feed-back speed | 3m/min |

Gauge | 1400mm |

Gas pressure | 0.4-0.8Mpa |

Похожие товары

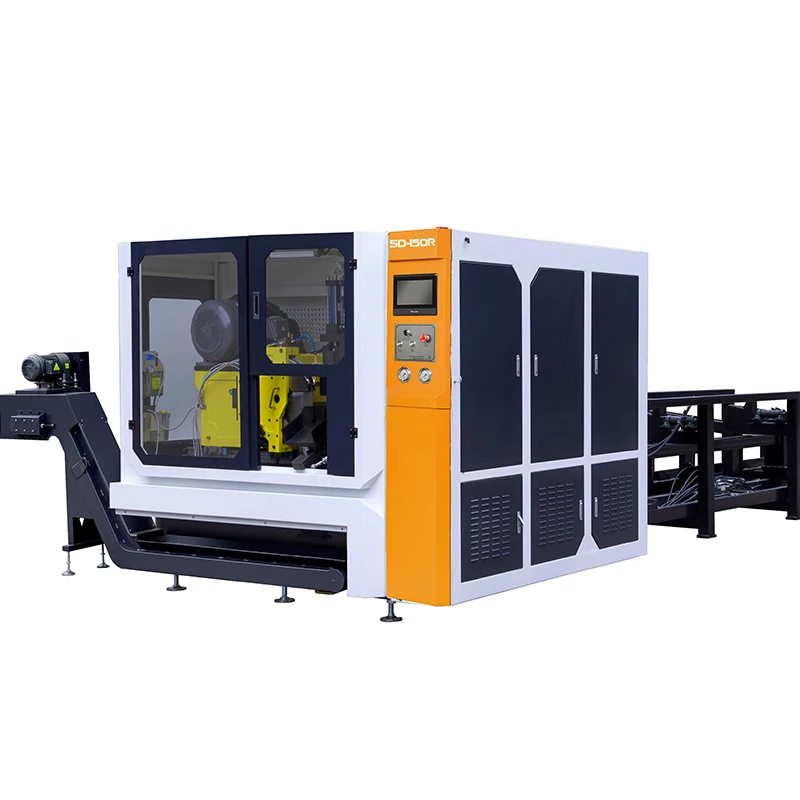

Хорошее качество быстрая скорость компьютерная управляемая металлическая циркулярная пила

Сверхмощный автоматический телескопический канал, роликогибочная машина для производства ящиков, скользящая направляющая

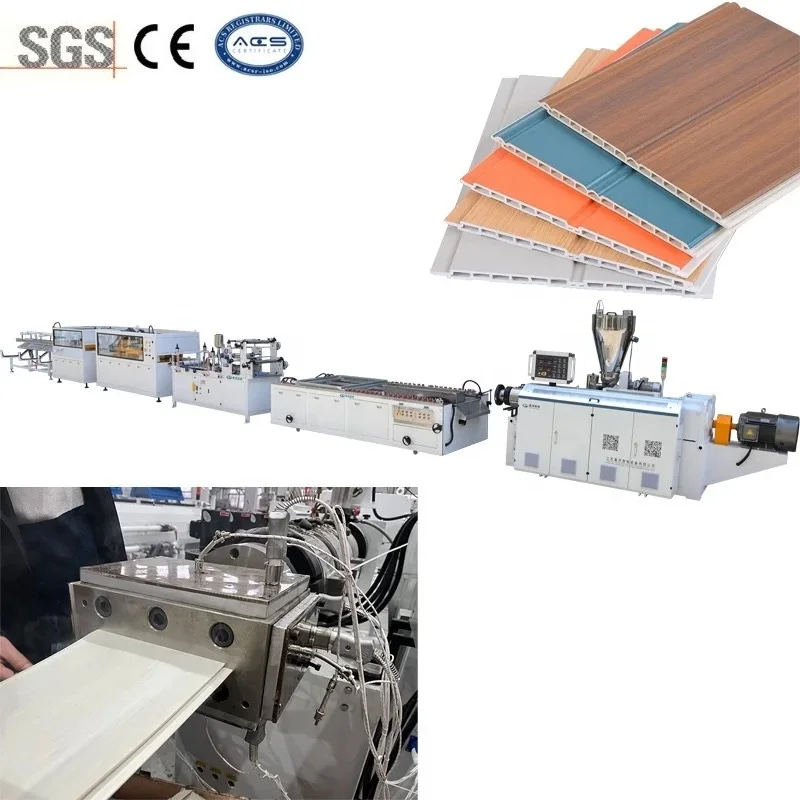

Upvc wpc машина для облицовки стен ПВХ

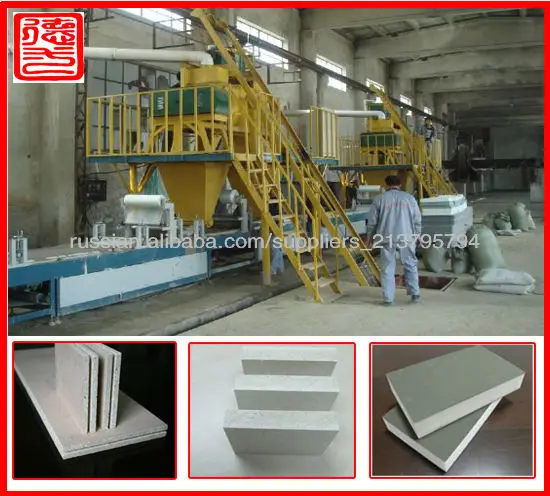

Линия производства Цементно-стружечная плита (ЦСП)

Высококачественная машина для резки стальных стержней с переменной частотой и длительным сроком службы

Мягкий камень искусственный фарфор Гибкая плитка делая производственную линию машины

Штукатурка для производства мрамора 150000 тонн в год линия по производству гипсового порошка

Новые поступления

Новинки товаров от производителей по оптовым ценам