Нагревательная мини печь типа SMT с 6 температурными зонами нагревательная система Рабочая панель фронтальной нагрузкой T961 светодиоды безопасности и компоненты BGA

- Категория: >>>

- Поставщик: Wenzhou Yingxing Import&Export Co. Ltd.

Сохранить в закладки 1600330567240:

Описание и отзывы

Характеристики

Intrduction

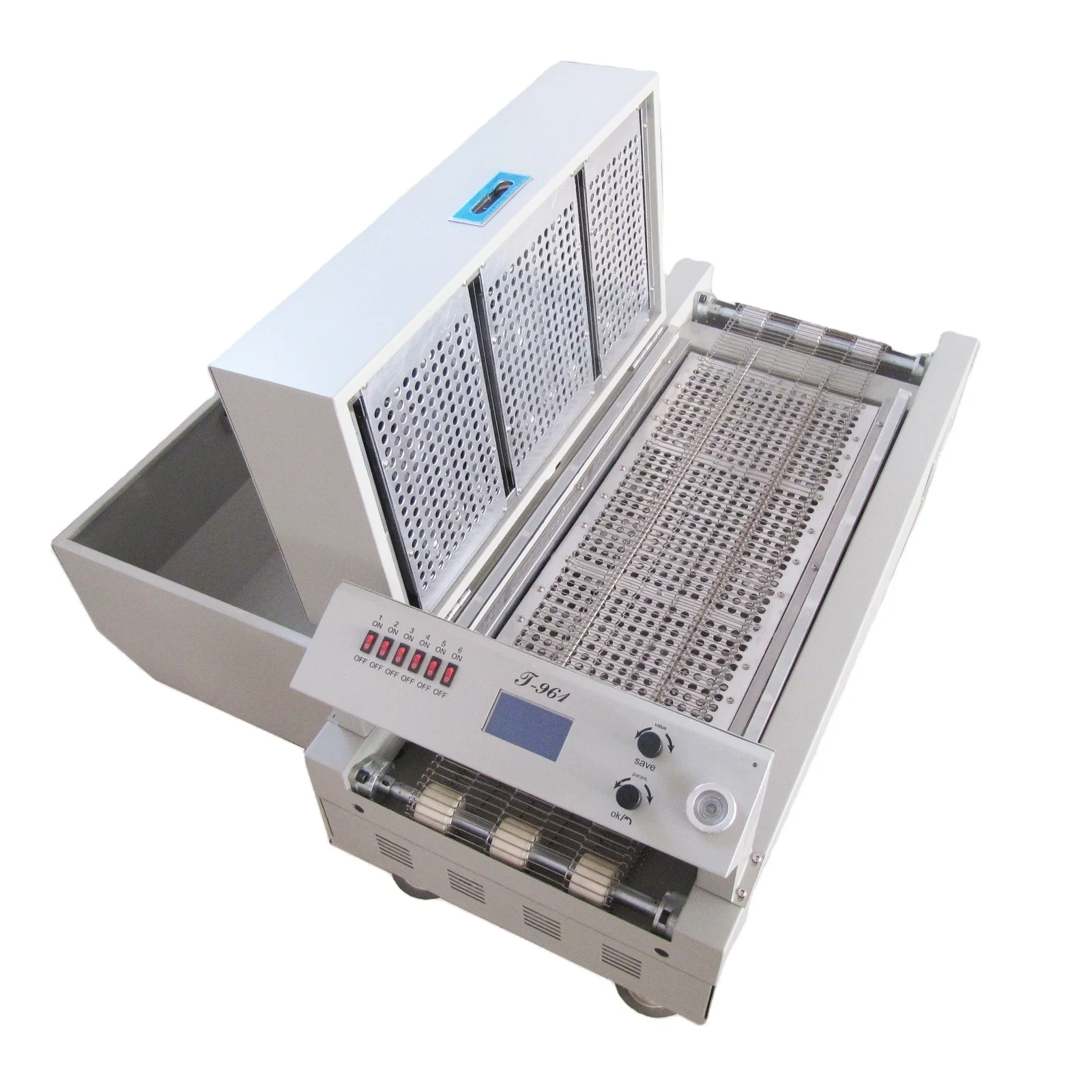

T961 is a Mini type SMT Reflow Oven with six temperature zone heating system.Front-load operation panel easy to handle and 8 curves can satisfy various soldering requirements.

Features

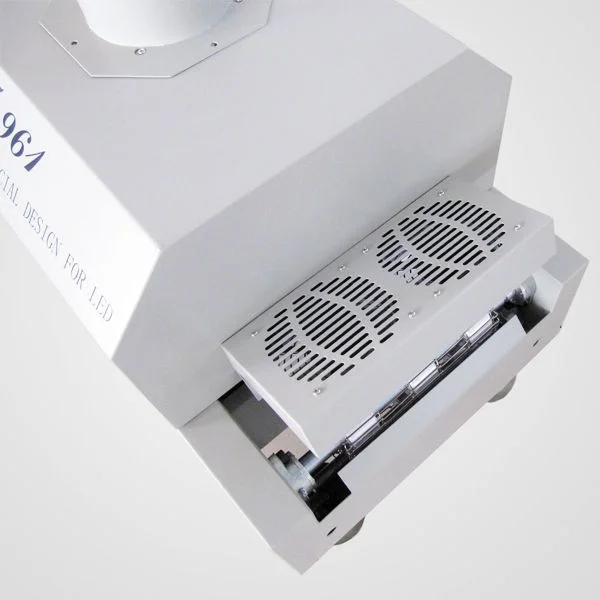

1. This machine selects IR and hot air heating technology , equipped with special designed wind wheel, speed stability and uniform temperature, suits for the LED and BGA components uninterrupted soldering.

2. This machine is equipped with the crawler-type and six temperature zones heating system, and each temperature zone uses independent PID controlling and up-down heating type, can make the inside temperature more accurate and well-proportioned, just takes about 7 minutes can heat up to the working temperature from the room temperature.

3. Intelligent temperature wave heating type, oversize capacity wave selection, have 8 temperature waves can satisfy various welding technological requirements.

4. Using programmable technology, preset the temperature wave memory storage function, can complete the whole welding process automatically according to your presetting wave.

5. Adopt the thermocouple temperature measurement and add the compensation circuit, make the temperature measurement more accurate, the wave more perfect.

6. Using PID intelligent temperature control technology; makes the temperature control more accurately. Adopts the imported large current solid-state relay non-contact output can effectively avoid the IC or circuit board damage due to the rapid or uninterrupted warming up, make the whole welding process more safety.

7. Transmission system adopts imported frequency conversion motor, PID closed-loop speed, smooth operation, speed adjustable range 0-290mm/min.

8. Adopt independent wheel structure and special stainless steel strut, durable wear-resisting runs smoothly, speed precision can reach ±10mm/min.

9. Independent cooling zone, to ensure the PCB board of low temperature .

10. Friendly human-machine operation interface, perfect LCD display, can watch the whole repairing process very clearly.

11. Ergonomic design, practical and easily operated. Good build quality but at the same time light weight and small volume allows the T-961 to be easily positioned, transported or stored.

2. This machine is equipped with the crawler-type and six temperature zones heating system, and each temperature zone uses independent PID controlling and up-down heating type, can make the inside temperature more accurate and well-proportioned, just takes about 7 minutes can heat up to the working temperature from the room temperature.

3. Intelligent temperature wave heating type, oversize capacity wave selection, have 8 temperature waves can satisfy various welding technological requirements.

4. Using programmable technology, preset the temperature wave memory storage function, can complete the whole welding process automatically according to your presetting wave.

5. Adopt the thermocouple temperature measurement and add the compensation circuit, make the temperature measurement more accurate, the wave more perfect.

6. Using PID intelligent temperature control technology; makes the temperature control more accurately. Adopts the imported large current solid-state relay non-contact output can effectively avoid the IC or circuit board damage due to the rapid or uninterrupted warming up, make the whole welding process more safety.

7. Transmission system adopts imported frequency conversion motor, PID closed-loop speed, smooth operation, speed adjustable range 0-290mm/min.

8. Adopt independent wheel structure and special stainless steel strut, durable wear-resisting runs smoothly, speed precision can reach ±10mm/min.

9. Independent cooling zone, to ensure the PCB board of low temperature .

10. Friendly human-machine operation interface, perfect LCD display, can watch the whole repairing process very clearly.

11. Ergonomic design, practical and easily operated. Good build quality but at the same time light weight and small volume allows the T-961 to be easily positioned, transported or stored.

Part List

· 1 x T-961 Reflow Oven

· 1 x Power Line

· 1 x Power Line

Paramenters

Specification | ||

Model | T-961 | |

Heating zone | upper 3 / down 3 | |

The operation direction | Left→right | |

The heating type | IR and hot air heating | |

Length of Heating Zone | 730mm | |

Max Width of PCB Board | 230 mm | |

Rated Power | 3.5KW | |

Speed of Conveyor Belt | 0-290 mm/min | |

Heating Up Time | Around 7min | |

Temperature Control Range | Room temperature - 300 ℃ | |

Temperature Control Accuracy | ± 1℃ | |

Temperature Distribution Deviation | ± 2℃ | |

L*W*H(mm) | 1000*466*445 | |

Machine Weight | 70KG | |

The power supply | 220V 50/60Hz | |

Front-load Operation Panel

Front-load operation panel avoids highly temperature in the panel to improve stability.

Temperature wave memory

Use programmable technology,preset the temperature wave storage,can complete the whole soldering process automatically according to your presetting wave.

8 waves can be preset

Easy operation,8 waves satisfy various soldering technological requirements,avoid to change temperature every time.

Temperature Control and Heating Insulation

PID Temperature control system makes temperature settling convenient,high precision of control and lower-power,it is improve

production efficiency.

Heating insulation layer in tank for insulation to keep temperature stability of six zones.

Packing details

Certifications

Wenzhou Yingxing Technology Co.,Ltd Specialises in SMT Production Line (PNP Machine)more than 9 years

Our Services

1.Video technical support

2.24-hour online support

3.Goods tracking support

4.Free broken parts(With 1 YEAR warranty)

2.24-hour online support

3.Goods tracking support

4.Free broken parts(With 1 YEAR warranty)

FQA

Q:How is the training?

A:After buying our machines,your engineers can go to our company or it is so easy to operate the machine according the training video and user manual,the user manual will come with the machine together.

A:After buying our machines,your engineers can go to our company or it is so easy to operate the machine according the training video and user manual,the user manual will come with the machine together.

Q:Is it hard to use these machines?

A:No,not hard at all.For our previous clients,at most 2 days is enough to learn to operate the machines.

A:No,not hard at all.For our previous clients,at most 2 days is enough to learn to operate the machines.

Q:Does your machines have quality certificate?

A:All of our machines have passed CE certificate,ISO14001(BCC),ISO9001(IQNET) and have own patent.

A:All of our machines have passed CE certificate,ISO14001(BCC),ISO9001(IQNET) and have own patent.

Q:The Warranty of the machine?

A:One year,then the parts will be free for the buyer in the warranty.

A:One year,then the parts will be free for the buyer in the warranty.

Q:English version for these machines?

A:Yes

A:Yes

Related Products

Похожие товары

Высокотемпературный SMT духовой паяльник PCB с CE

2 710 897,50 ₽

Машина для оплавления Heller smt Heller 1826 MK7 для паяльной машины SMT

206 028,21 ₽

2024 Горячая Распродажа, сверхстабильная настольная Smd инфракрасная Горячая воздушная конвейерная Smt оплавильная паяльная печь для сварки печатных плат

1 377 135,93 ₽ - 1 409 666,70 ₽

ITECH RF-B630T SMD Пайка методом оплавления припоя горячим воздухом машины высокой производительности 220V 6 зон печь оплавления SMT машина для Pcb пластина для пайки

162 545,42 ₽ - 173 389,01 ₽

Печь оплавильного T-960w горячего воздуха Puhui Smt для светодиода PCB припой 5 6 нагревательный зонный конвейер инфракрасный нагреватель

Простая в установке печь для оплавильного припоя без свинца по конкурентоспособной цене с компонентами сердечника PLC, новое состояние для индустрии SMT

3 036 205,20 ₽ - 3 253 077,00 ₽

T-960 Puhui инфракрасный LED канала печь оплавления SMT для BGA паяльная станция

Новые поступления

Новинки товаров от производителей по оптовым ценам

Оптовая продажа 100% Рафинированное Масло из семян подсолнечника малазия масло для приготовления пищи

GY031 металлическая рамка пользовательских игровых сидений Sim гоночные игровые сиденья симулятор вождения кабины для Xbox 360 Logitech G25 G27 G29 G920

88-143 $

Роскошные пользовательские островные стулья современные кухонные с выдвижными ящиками и раковиной кухонный шкаф U-образной формы из нержавеющей стали

160-180 $

2025 хорошее качество новый запуск мульти изогнутый 43-дюймовый + 24-дюймовый двойной экран игровой металлический автомат

750-800 $

12 вольт реле автоматической задержки таймера 24 В постоянного тока без NC переключатель выключения/включения WM YS010

3,50-4 $

Горизонтальный станок для сверления стекла круглого отверстия оборудование обработки заводская цена

3 400-3 600 $

Японский корейский мультяшный маленький свежий самоклеящийся блокнот для заметок студенческих подписей стикеры и наклейки

Симпатичный горшок для кошек уникальный 8-дюймовый керамический растений большой бонсай со съемным блюдцем

1,38-3,06 $