Наружная подстанция 11 кВ 0 4 компактная полная трансформаторная 800 ква

- Категория: Motor Driver >>>

- Поставщик: Zhejiang Nengrong Electric Power Equipment Co. Ltd.

Сохранить в закладки 1600331349541:

Описание и отзывы

Характеристики

Main technology and relevant requirements of high voltage motor auto coupling step-down starting cabinet. It includes the technical requirements for the design, type selection, supporting, structure, performance, manufacturing, installation, test, commissioning, technical service, maintenance and quality assurance of the system, equipment and its accessories.

1.2 the technical agreement puts forward the minimum technical requirements, does not specify all technical details, and only quotes some relevant standards and specifications. The supplier shall ensure to provide high-quality products that meet the agreement and relevant latest industrial standards.

1.3 this technical agreement is an annex to the order contract and has the same effect as the text of the contract.

1.4 matters not covered in this technical agreement shall be settled by both parties through negotiation.

1.5 in the process of equipment manufacturing, if the demander requires modification due to other reasons, the supplier must meet the demander's requirements.

1.6 the technical agreement specifies the supply scope of the contract equipment. The supplier must ensure that the equipment provided is brand-new, advanced, mature, complete, safe and reliable, and the technical and economic performance of the equipment meets the requirements.

2. Technical standards and use environment

2.1 technical standards

The design, manufacture, inspection and test of main and auxiliary equipment of high-voltage solid-state soft start device adopt the latest national standard GB and meet the corresponding IEC standards. The main standard numbers are as follows:

GB / t2423.4-1993 basic environmental test procedures for electrical and electronic products test DB: alternating damp heat test method( eqv IEC 60068-2-30:1980)

GB / t2828-1987 sampling procedures and sampling tables for batch by batch inspection by attributes (applicable to continuous batch inspection)

GB 2900.19 Electrotechnical terms -- high voltage test techniques and insulation coordination

GB / T 2900.20-94 Electrotechnical terminology high voltage switchgear

DL / T 593-2006 common technical requirements for high voltage switchgear and control equipment standards

GB 311.1-1997 insulation coordination of high voltage transmission and transformation equipment

GB / T 3797-2005 electrical control equipment

GB / T 14048.1-2000 low voltage switchgear and controlgear - General

GB / T 2682-1981 colors of indicator lights and control buttons in complete sets of electrical equipment

JB / DQ 8124 basic technical requirements for cable equipment

DL / T 404-1997 technical conditions for ordering indoor AC high voltage switchgear

Gb1208-97 code for design of relay protection and automatic devices for power installations

Solid insulating materials -- Determination of relative leakage opening index under wet conditions

GB / t5169.11-1997 fire hazard test for electrical and electronic products -- hot wire test method and guide for finished products

GB 4208-1993 degrees of protection provided by enclosures

Basic environmental conditions and test conditions for transportation and storage of mechanical and electrical products

Jb3284-1983 basic environment and test conditions for transportation and storage of motor and electrical products

GB / T191 Pictorial marking of packaging, storage and transportation

Gb9969.1 general rules for operating instructions of industrial products

Low voltage switchgear and controlgear -- low voltage electromechanical contactors and motor starters

Low voltage switchgear and controlgear contactors and motor starters

Jb5346-1998 series reactor standard

Gb10229-88 reactor

All the above codes, codes and standards shall be subject to the latest version implemented nationally or internationally.

2.2 service environment

Altitude: ≤ 1500m

Maximum monthly average relative humidity: 95%

Maximum ambient temperature: + 45 °

Minimum ambient temperature: - 25 °

24h average maximum temperature in the hottest month: + 30 °

There is no explosive medium in the installation site. The surrounding medium does not contain gas and conductive medium that damage the insulation performance. It is not allowed to be filled with water vapor and serious mold. The use site should not have strong external magnetic induction intensity.

3. Scope of supply

3.1 provide the main technology and services of a complete set of high-voltage auto coupling step-down start-up one driven one start-up cabinet necessary to meet the requirements of this technical annex.

The main components include: autotransformer, disconnector, current transformer, voltage transformer, high-voltage vacuum contactor, fuse, digital instrument with 4-20mA current transmitter, special microcomputer comprehensive protection device for motor, button, signal lamp, transfer switch, temperature patrol detector, LED lighting, complete cabinet, copper bus sleeve high-voltage heat shrinkable tube, etc.

The list of supplied equipment is as follows: (see the attached table for details)

Serial number name Soft start model Company quantity Motor power Load type

one High voltage auto coupling step-down starting cabinet NRZOQDG-10-500kW platform one 500kW/10kV

two

three

four

4. Technical requirements

1. The high-voltage auto coupling step-down starting device is one by one, 10kV input and 10kV output. Meet the requirements of long-term continuous operation, and start, run and stop quickly, safely and reliably.

2. The high-voltage motor auto coupling step-down starting cabinet has the following functions: switch on / off by button operation of the cabinet, switch on / off by local button box operation, and switch on / off by DCs linkage of remote background automation panel;

Output signal contact:

Operation status signal: passive normally open contact stop status signal:

Fault status signal of passive normally closed contact: passive normally open contact + passive normally closed contact

Ready signal: passive normally open contact and passive normally closed contact

External input signal contact:

Remote start signal input: passive normally open contact remote shutdown signal input: passive normally closed contact DCS start signal input: passive normally open contact (self holding contact)

Switch cabinet ready signal input: passive normally open contact

3. The incoming and outgoing lines of the high-voltage motor auto coupling step-down starting device are in the way of cable incoming and outgoing, and the device can meet the requirements of two cables incoming and outgoing.

4. The installation, commissioning and maintenance of the device cabinet can be carried out on the front and back.

5. The secondary control power supply shall be provided externally by AC220V.

6. Color of high voltage auto coupling step-down starting cabinet: according to user's requirements

7. Arrangement of high voltage auto coupling step-down starting cabinet: each set is placed separately.

4.1 technical performance

4.1.1 working principle

The autotransformer step-down starter connects the autotransformer between the motor and the power supply line to start or reduce the motor starting current. The autotransformer is provided with taps of 50%, 65% and 80% line voltage to realize step-down starting. The advantage of this starter is that under the same starting torque, the line current of autotransformer step-down starter is lower than that of resistance starter and reactance starter.

When the starting voltage of the motor is 50%, 65% and 80% of the line voltage, the starting current of the motor is 25%, 42% and 64% of the full voltage starting current respectively. Due to the high cost of autotransformer step-down starter, this starter is only used for large motors. The autotransformer is an inductive load, and the power factor of the whole load circuit is low during startup. The step-down starter of autotransformer can be divided into two types: open circuit commutation type; Closed circuit commutation type. The starting process time of AC motor is very short, generally from a few seconds to about a minute. After starting, the starting transformer used by step-down will be cut off.

4.1.2 protection function

Protection functions: overcurrent protection, under current protection, phase loss protection, overvoltage protection, motor start timeout protection, three-phase current imbalance protection, motor overload protection.

4.1.3 main performance indicators: motor parameters and relevant requirements involved in this Agreement (the following parameters shall be provided by the buyer)

Motor parameters

Motor type: squirrel cage motor winding motor synchronous motor

Motor model Wiring mode: Port y Mouth

Rated voltage Ue 10kV Power factor cos

Rated current IE A Motor rotor moment of inertia

Rated power p 500KW Maximum torque / rated torque Tmax / Te

Motor frequency Hz 50Hz Locked rotor torque / rated torque to / Te

Rated speed Locked rotor current / Rated Current IO / IE

Load parameters

Load type Fan Water pump Other loads

Basic parameters model

power 500Kw Static resistance moment

Rated speed rpm Starting torque

Power parameters

Power supply mode power grid Grid capacity KVA Short circuit capacity of power grid

diesel oil Generator capacity KVA Diesel motor over

Other parameters

Control power supply 1,AC220V 2,DC220V

Incoming and outgoing line requirements 1. Top in and bottom out 2. Down in down out 3. Others:

field wiring Main circuit cable specification: Specification of control loop cable:

Start / stop requirements 1. No load start 2. On load start 3. Soft parking 4. Other

Motor winding temperature detection

1. This function is not required 2. This function is required

1,Circuit temperature detection 2. Sensor type(

Grid side contactor 1. Without grid side contactor 2. Contactor with grid side

Load type Three phase medium and high voltage asynchronous motor

AC voltage 10000VAC-15%~+10%

Insulation voltage Line voltage absolute voltage

10kV 42kV

Overload capacity Continuous: 120% overload: 150% / 60s

frequency 50Hz

Startup multiple 5-8 times autotransformer tap: 60% 80%

Cooling mode Self cooling

Installation occasion indoor

Start time If the starting time is 2 minutes, it shall be cooled for 6 hours before starting again.

Temperature resistance grade Reach grade F (155 ℃).

loss The loss of dry-type core starting autotransformer is lower than that of oil immersed autotransformer.

noise Less than 50dB

Structure mode Core epoxy casting

temperature rise Under rated load, 1.35 times overload temperature rise is less than 90K

Inductance error + Within 3%

coil The coil is cast by epoxy resin, which has the advantages of flame retardant, self extinguishing, maintenance free, high mechanical strength, good insulation strength, small partial discharge and long service life

core Dry type autotransformer manufacturing technology is adopted, with low vibration, low noise and small magnetic leakage

4.2 cabinet structure characteristics

small floor area, convenient installation, indoor installation and natural cooling.

the self coupling step-down starting cabinet has reasonable structure, reliable and effective electrical five prevention interlocking to meet the anti misoperation requirements;

the cabinet body is welded with high-quality cold-rolled plate angle iron channel steel, and the panel is sprayed with powder. The whole cabinet structure is firm. The cabinet body is welded with standard angle iron, the transformer mounting beam is welded with channel steel, and the instrument door and front door are welded with 2.5mm thick cold-rolled plate and sprayed with plastic( The cabinet frame is welded with angle iron, and the transformer mounting beam must be welded with channel steel to fix the transformer)

the door hinge adopts galvanized large hinge;

the door lock adopts explosion-proof interlocking structure, and it is forbidden to directly use conventional door lock (when the pressure generated in the internal short circuit of the cabinet is released, the door lock in front of the cabinet will not be damaged, causing personal safety to the operator);

the top of the cabinet is equipped with explosion-proof relief gland, and the bolts at the release port of the relief gland are bakelite or plastic bolts;

the cabinet door shall be provided with anti misoperation signs;

operation instructions and operation flow chart of cabinet door;

all primary components in the cabinet shall be grounded with independent grounding conductor / connected to the primary main grounding bus in the cabinet.

the sides of the sealing plates on both sides of the cabinet must have knock down holes for the main grounding copper bar. The manufacturer shall make the grounding copper bar to facilitate the connection with the main grounding grid on site;

the grounding of each primary component in the cabinet must be connected to the main grounding copper bar in the cabinet by independent grounding wire or grounding copper bar, and serial connection is prohibited.

the zinc oxide arrester is provided with an independent grounding bus, which is led to the main grounding bus of the cabinet;

the copper bar in the device adopts tinned sleeve high-pressure heat shrinkable pipe, and the overlapping surface is embossed to ensure that the connection between the copper bar and the copper bar on the overlapping surface is firm and reliable, and the fracture of the bus bar is smooth and round without burrs, so as to prevent tip discharge. The burr after punching (drilling) must be polished after corner cutting.

the grounding wire of primary components must be connected with transparent plastic sheathed multi strand flexible wire crimping nose or tin filling (hammering is prohibited), and the section of primary grounding wire shall not be less than 16 square meters;

the important fixing positions of secondary line and high-voltage live conductor must be bound with stainless steel ties, and plastic nylon ties are prohibited. Prevent the nylon tie from aging, the secondary line from falling off and colliding with the high-voltage charged body, resulting in potential safety hazards to the operation of the equipment;

a pair of normally open and normally closed contacts are reserved for the auxiliary of disconnector, a pair of normally open and normally closed contacts are reserved for the door travel switch, a pair of normally open and normally closed contacts are reserved for the auxiliary of contactor, a pair of normally open and normally closed contacts are reserved for the fault contact of capacitor bank, and the above auxiliary nodes are passive node output terminal strip;

The rear sealing plate of the starting cabinet is composed of upper and lower parts, which are respectively perforated and welded with iron gauze mesh;

4.3.1. Disconnector

In order to ensure the personal safety of maintenance personnel, isolation switches for maintenance are installed on the power side of the startup cabinet to improve safety and reliability.

4.3.1.1 model: gn19-12-630a

4.3.1.2 type: indoor manual operation three-phase linkage type

4.3.1.3 rated voltage: 12KV

4.3.1.4 number of phases: 3 phases

4.3.1.5 rated current: 630A

4.3.1.6 rated short-time withstand current: 25 Ka, 3S

4.3.1.7 rated peak withstand current: 25kA (peak)

4.3.1.8 operating mechanism: Manual

4.3.1.9 specific creepage distance (mm / kV): 25

4.3.1.10 installation in cabinet

4.3.1.11 mechanical life: the number of continuous operations shall not be less than 2000 without mechanical adjustment, maintenance or replacement of components.

4.3.2. High voltage vacuum contactor

4.3.2.1 model: jcz5-12d-630a

4.3.2.1 type: fixed installation in cabinet

4.3.2.1 rated voltage: 12KV

4.3.2.1 rated current: 630A

4.3.2.1 1min power frequency withstand voltage: 42KV;

4.3.2.1 secondary control voltage: AC220V

4.3.2.1 purpose: mainly used for dynamic frequent closing and starting motor.

4.3.3. Voltage transformer

4.3.3.1 model: jdz-10

4.3.3.1 type: indoor dry-type voltage transformer

4.3.3.1 rated voltage: 10KV

4.3.3.1 rated capacity: 80va

4.3.3.1 secondary voltage: 100V

4.3.3.1 rated output standard value and accuracy level: 400va, level 0.5.

4.3.3.1 medium: epoxy resin casting insulation half seal

List of main components of the device

Equipment name: high voltage motor auto coupling step-down starting cabinet

Model and specification: nrzoqdg-10-500kw

Serial number Equipment name Model and specification Company quantity Remarks (width, height and depth)

one High voltage motor auto coupling step-down starting cabinet NRZOQDG-10-500KW platform one 1400*2600*1600mm

two

three

four

five List of main components of single cabinet

six

seven

eight Special microcomputer integrated protection device for motor Nrddj-i (overvoltage, low voltage, open delta voltage protection, overcurrent protection, overcurrent breaking protection, fault alarm node, switch position status monitoring, LCD with RS-485) platform one Energy capacity power

nine Isolating switch Gn19-12-630a auxiliary 4 opening and 4 closing platform one Energy capacity power

ten High voltage AC vacuum contactor JCZ5-12D-630A platform three Energy capacity power

eleven Autotransformer SRQKSGL-10-500W platfo

| high voltage motor auto coupling step-down starting cabinet | 10KV | 500KW | 630KW |

| high voltage motor auto coupling step-down starting cabinet | 11KV | 710KW | 750KW |

rm one Energy capacity power

twelve Fuse XRNP1-12/0.5A platform three Energy capacity power

thirteen Voltage transformer JDZ-10 10/0.1KV platform two Energy capacity power

fourteen Current transformer LZZBJ9-10A4G 0.5/10P10 platform three Energy capacity power

fifteen Zero sequence transformer LXK-10 platform one Energy capacity power

sixteen Lightning arrester HY5WD-13.5/31 group one Energy capacity power

seventeen Intermediate time relay set one Energy capacity power

eighteen Signal lamp button change-over switch set one Energy capacity power

nineteen Miniature circuit breaker set one Energy capacity power

twenty Door travel switch set one Energy capacity power

twenty-one Electromagnetic lock live display set one Energy capacity power

twenty-two Insulator sensor set one Energy capacity power

twenty-three Sensor insulation set one Energy capacity power

twenty-four Branch copper bar / sleeve heat shrinkable pipe Tmy-40 6 sets of heat shrinkable tubes set one Energy capacity power

twenty-five Grounding bus TMY-30*3 platform one Energy capacity power

twenty-six Condensation heater WSK-DJR set one Energy capacity power

twenty-seven Complete cabinet and accessories set one Energy capacity power

twenty-eight

twenty-nine

thirty

remarks 1. The main components in the cabinet are the standard products of the company. The control mode of the self coupling start cabinet is: the button of the cabinet is closed and opened, the remote user's background automation level DCS linkage is closed and opened, and the local button box is closed and opened,

2. The cabinet body is made of cold-rolled plate angle iron channel steel welded and sprayed with plastic, the door plate is made of 2.5mm thick cold-rolled plate sprayed with plastic, and the bus is copper bus; 3. Protection mode of starting cabinet: overcurrent, overcurrent current breaking protection, zero sequence current protection, overvoltage protection and low voltage protection

Похожие товары

В наличии Высокое качество ISO25 APU08 Сверлильный Патрон Диапазон обработки 1-8 мм для дрели

Поставщик оборудования для упаковочной машины Soontrue, запасные части, сервопривод для блока подачи

Легкий вес сервомоторный двигатель ЧПУ низкая стоимость мотор сервопривода с приводом

Новинка 2021, оптовая продажа, сервопривод с контроллером, сервомотор для литья под давлением

Сервопривод переменного тока 750 Вт серии A5 Миноза А5 жедонт3520

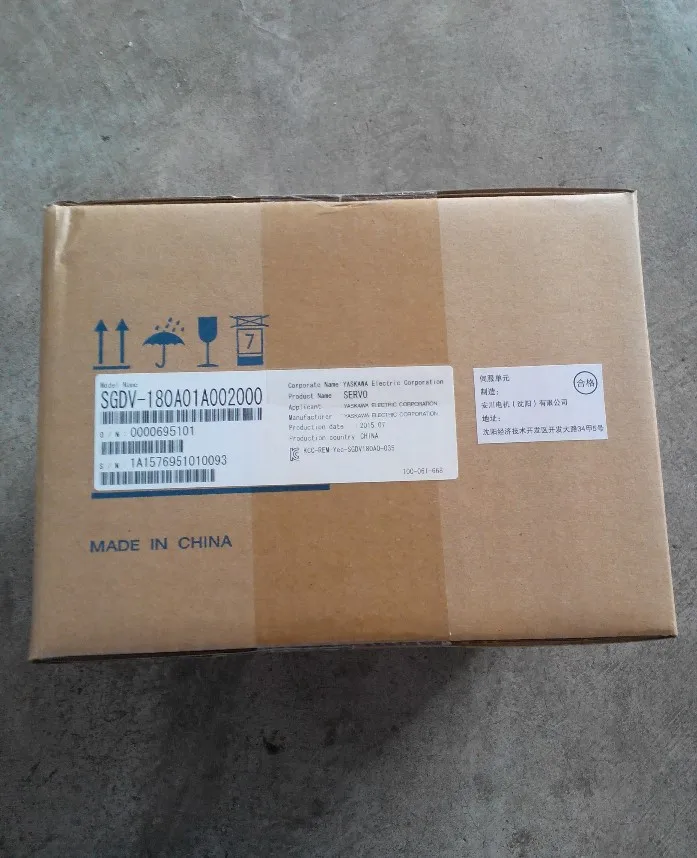

Yaskawa сервопривода SGDV-180A01A002000 2KW Новый и оригинальный

Оптовая продажа цена ЧПУ fanuc A06B-6290-H104 диски Китайской торговой Серво привод постоянного тока

Новые поступления

Новинки товаров от производителей по оптовым ценам