Коммерческий 200 тонн в день большой мука мельницы размольная машина для производства пшеничной муки измельчения пшеничной/автоматическая мельница Чакки Атта

- Категория: >>>

- Поставщик: Shijiazhuang Huanpai Machine Co. Ltd.

Сохранить в закладки 1600342481998:

Описание и отзывы

Характеристики

Shijiazhuang Huanpai Machine Co.,Ltd is a professional manufacturer of all types of flour milling machine for wheat/maize/corn, Our production capacity is from 10 ton to 500 ton per day. We provide turnkey project of our machienry, including special design, installation instruction, commissioning and training workers.

Our products are exported to Australian, America, Canada, Belgium, Egypt, Algeria, Zambia, Congo, Kenya, Ethiopia, Uganda, Yemen, Tanzania, Tajikistan, Afghanistan, Vietnam, Israel, Mozambique,Kazajastan and other country.

We have been in this field for more than 50years, and has grown into a a large supplier of feed machine with engineering automation control technology, product research, development and manufacturing, projects design and installment. Our equipment is widely exported to more than 30 countries and regions. Our professional engineers can design the machine as per your requiremnt. The complete set feed machine is suitable to small, middle and large feed plant to make feed powder, feed pellet for chicken, fish, sheep, cow etc.

SPECIFICATIONS FOR 200ton/24hour wheat flour milling machinery 1.Technology in cleaning part: The technology of three screening, two scourer, two destoner, two damper, and three magnetic separator. 2.Technology in milling part: 12 sets of FMFQ10×2 Roller mill, 4sets of 6*24K High-efficiency six-section plansifter, 4sets of Double purifier, one set of FSFG4*24K Checker sifter consists of the milling technology of five break, eight reduction, two coarse, two tail, four purifier, and one checker. 3.Production: 200 tons wheat/24H. 4.Kinds of final products: 1)Wheat flour: according to the customer's requirement, the final product can be grade 1 flour, grade 2 flour, standard flour or other special-purpose flour. The quality of flour accords with the requirements of GB1355-86 (China flour standard). 2) Byproduct: wheat germ and bran. 5.Power supply: About 680kW. 6.Used under condition: Voltage, 380V; Frequency, 50Hz; Below an elevation of 1000m. 7.Dimension of the main workshop: triangle-framed workshop, with 39m long 9m wide and 11m high (under beam). 8.Container: 13×40' 9.Delivery time: within 90 days after the advance payment | ||||||

Main Features

Complete set of wheat flour machine can be divided into four parts: cleaning part, milling part, packing part:

1. Cleaning part

to clean out the middle and small impurity from wheat. e.g., dust, stone, magnetic material, wheat was bitten by insect and so on.Includes beating, screening, destoner, magnetic separator and dampening.This section is to prepare for milling part and to protect the machinery as well.

2. Milling part

The second step, to mill the grain and separate the flour, bran and other by-product:

(1) Mill: mill the grain to break the integrity by the roller moving

(2) Sifter: to separate the flour, bran and other by-product, also separate large size and small size to ensure flour quality.

3. Packing part

The third step, the packing machine can be manual or automatic weighting and packing.

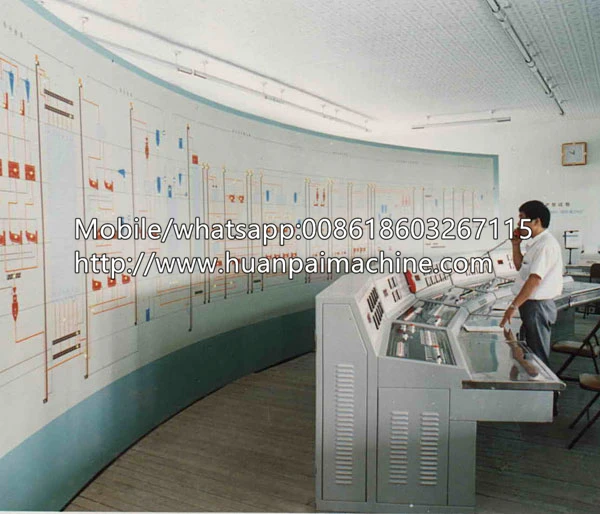

4. PLC controlling system

To controlling the whole set of machinery to work well and showing the process of working.

Name: roller mill

Brand: huanpai

Original: China

1.Laser precision cut parts formed on a CNC press brake

2.Two parts construction including a cast iron base and steel machine structure, surface spray-paint by the electrostatic technique

3.roller mill features can be customer designed to meet your requirement.

Name: :FSFG series plansifter

Brand: Huanpai

Original: China

Mian types:FSFG4×16,4×22,6×22,6×24

It is the efficient level revolving plansifter.It is composed of flour or six or eitght isolate storehouse.It can adapt to classify material under the mill of every screen according to the requirements of flour mill.The effect of screening is fine, operation is reliability, operating maintenance is convenient, low power consumption,high efficiency.It is the main plansifter for large and middle grain processing plant.

Name: 50ton wheat flour milling machine

Brand: huanpai

Original: China

Our products are exported to more than 30 countries in the world. Our factory promises: reasonable prices, High-quality goods s and satisfactory after-sales service

Pre-sale service.

* Inquiry and consulting support.

* Special design.

* View our Factory.

Installation services

An experienced engineer will be send to project site to ensure the successful completion of each phase of the plant, which enables us to provide professional consultation, design, manufacture, installation and project management services.

Quality is the life of an enterprise.Adhering to "Customer's success is our goal", the company has built up a good reputation in domestic and foreign markets.

The company is willing to strengthen the cooperation with colleagues at home and abroad to develop new products and co-create brilliance with new appearance, innovative consciousness, and sincere enthusiasm.

1. Q: Which kind of flour mill can you processed? And what about the capacity

-- A: we can offer wheat flour mill and maize / corn flour mill with the capacity 5T/24H ------1000T

2. Q: what is the basic processing step?

-- A: Full automatic line:Cleaning the raw material--Milling the material into flour--Packing the flour into bags.

3. Q: Which kind of wheat we can use in the processing line?

-- A: Durum wheat, Hard wheat, Soft wheat

4. Q: Which kind final products we can get from the wheat flour mill? And the usage of the products?

-- A: Semolina(very high gluten)--Pasta flour (gluten >13%)---Bread

Plain flour (gluten 9%-12%)--Noodle, Steamed bread Soft flour (gluten<8%)---Cake ,Biscuit

5. Q: Which kind of final products we can get from the maize / corn flour mill?

-- A: maize flour, maize grits (meal), maize germ, bran and animal fodder.

6. Q: Are you manufacturer or trading company?

-- A: We are professional wheat flour milling machine/maize flour mill manufacturer with more than 20years experience. And we have our own factory, welcome you come to China and visit our factory.

7. Q:Never engage in flour industry.Don't understand how to operate the flour milling machine?

--A:Your don't need to worry anything, Our professional Chinese engieer will go to you country to help you install the machinery and train workers.

*Training how to install the machine, training how to use the machine,maintainenance.

* Engineers available to service machinery overseas.Providing professional support for the consultation of engineering technology and technical problem.

8. Q:what is the basic processing step?

--A:Full automatic line,Cleaning the raw material--Grinding the material into flour--Packing the flour into bags.

9.Q: How does your factory do regarding quality control?

--A:Quality is priority. We always attach great importance to quality control from the very beginning to the end of the production. Every product will be fully assembled and carefully tested before it's packed for shipment.

SHIJIAZHUANG HUANPAI MACHINE CO., LTD | ||

Contact Name: | Mary | |

Mobile (whatsapp): | 0086 18603267115 | |

Tel: | 0086- 311-8782 0292 | |

FAX: | 0086 -311-8782 0202 | |

Email: | hpmachine(at) 126.com | |

//www.huanpaimachine.com | ||

Похожие товары

Квадратные концевые фрезы HRC 45 из карбида вольфрама с 2 канавками

Портативная мельница для перца, бутылка для приправ, ручная мельница для соли и перца, мельница для специй, кухонная утварь

Профессиональные электрические мельницы для перца высшего качества

Startnow 5 шт. фрезы Два флейты Спираль конических фрез со сферическим концом алюминиевые пластмасс CNC фрезерный станок с цифровым управлением для вставные резцы

Кухонные современные многоразовые турецкие инструкции molinillo de pimienta мельница для перца и соли мельница для перца

Твердосплавные сверкающие концевые фрезы с одной канавкой, резак для акриловых фрез

steel salt and pepper grinder set manual sliver pepper grinder salt grinders and pepper mill shaker mills set

Новые поступления

Новинки товаров от производителей по оптовым ценам