Производственная линия из гофрированной трубы с одной стенкой 8 50 мм для изготовления пластиковых полиэтиленовых полипропиленовых ПВХ защитных трубок

- Категория: >>>

- Поставщик: Zhangjiagang Beierman Machinery Co. Ltd.

Сохранить в закладки 1600342951036:

Описание и отзывы

Характеристики

Zhangjiagang city Beierman Machinery single wall corrugated pipe making machines , specially designed for PE single wall corrugated pipes making, we also supply PP, PVC single wall corrugated pipe making machines.

there are 8-50mm corrugated pipe line , there are 63-75-110mm corrugated pipe line.

Pipe Diameter range: 8mm,12mm,16mm, 20mm, 25mm, 32mm,40mm,50mm. single wall corrugated Pipe Outlets.

Major parts of PP PE single wall corrugated pipe making line :

No. | Major parts | Detail information |

1 | Vacuum loader+hopper dryer | loader pump:0.75KW; hopper heater:6KW;blower:0.25KW;hopper volume:50L. |

2 | SJ50/30 Single screw extruder | Driving motor:11KW,heating:4KW*3;cooling:0.18KW*3 |

3 | Die head with forming mould | 8-50mm:8mm,12mm,16mm,20mm,25mm,32mm,40mm,50mm; material:40Cr, 54pairs forming module per set. |

4 | Forming machine | Driving motor:2.2KW,Cooling:0.18KW*3,material:40Cr |

5 | Double station winder | 16NM,winding release:air cylinder. |

Advantages

- world famous brands major parts:

Motor | SIEMENS |

Inverters | ABB/DELTA/LS |

Contactors | Schneider/SIEMENS |

Temperature controllers | OMRON/RKC/FUJI |

PLC system | SIEMENS/DELTA |

- Skilled workers for machines producing

- Experience engineers all with passports ready for customers services

- Good Prices get from square quantity major parts purchase with lower cost

- Full line running test for customer checking before delivery

- Packaging: films for the machine, wooden case if required is no need fumigate; bubble films packaging

- We suggest the customer to purchase poly-wooden case packaging; if no, we will fixed the machines on containers walls with steel wires

- Shipping: By Sea or Train

- BEIERMAN MACHINERY was established by three skilled technician/engineer/sales for plastic extruding line, plastic recycling lines producing, sale and services.

- We have 3000 square meters working house for machines making, there are 40 workers for machines producing and a 5 engineers service team for the machines running test, installation, workers training and machines repairmen.

- we have already get CE certificate for our machines and factory, which ensured the high quality level of all machines we are producing

- we will attend several home and abroad plastic machines industry fairs to show the customers our quality, machines and services.

- there will be 1-2 new produced machines will be showed to the customers every year.

- we already established cooperation with the customers from Middle East, Southeast Asia and south America countries.

1,Mixing unit (Vertical , or Horizontal),high speed mixer~~~for PVC powder;

Ribbon mixer, low speed mixer~~~for PVC powder;

Hopper dryer mixer~~~for plastic granules;

Color mixer~~~for plastic granules.

2, PC/PMMA/ABS LED light diffuser,bottom tube making line.

3,Supermarket Price tag profile production line; Soft seal production line; Rigid rod production line.

4,Single screw extruder;

5,Conical twin screw extruder;

6, 2layer; 3 layer;4 layer PPR pipe co-extrusion line; PPR, PE, HDPE, PE-RT pipe production line;

7, Corrugated pipe extrusion line (Single wall corrugated; Double wall corrugated);

8, 3 layer PVC pipe co-extrusion line; PVC pipe production line;

9, PVC 2 cavity pipe production line;

10, PVC 4 cavity pipe production line;

11,Pipe belling machine;

12, PVC rain gutter profile line; Trunking/panel profile line;WPC profile production line; and 2 layer PVC profile co-extrusion

line;

13, Granulating line-water ring granulating,or string granulating (PP PE );

14, Granulating line-hot die face granulating (PVC).

Pre-sales services

we will take customers to visit our factory and check the machines quality from airport/bus station/train stations

- we will re-designed the machines according to customer's different raw material formulations: driving motors power, electric power model, wall thickness of barrel, control method

After-sales services

we will offer electric diagram, installation diagram, usage manual

- we will offer the customers online introduction to solve the machines problems/send engineers for customers machines installation, running test, workers training, machines repairmen services.

- we will offer customers spare parts at cost prices all life long of the machines.

Похожие товары

Высокотемпературное Неизолированное сверло 12 мм Круглый Синтетический фианит с цирконом незакрепленный драгоценный

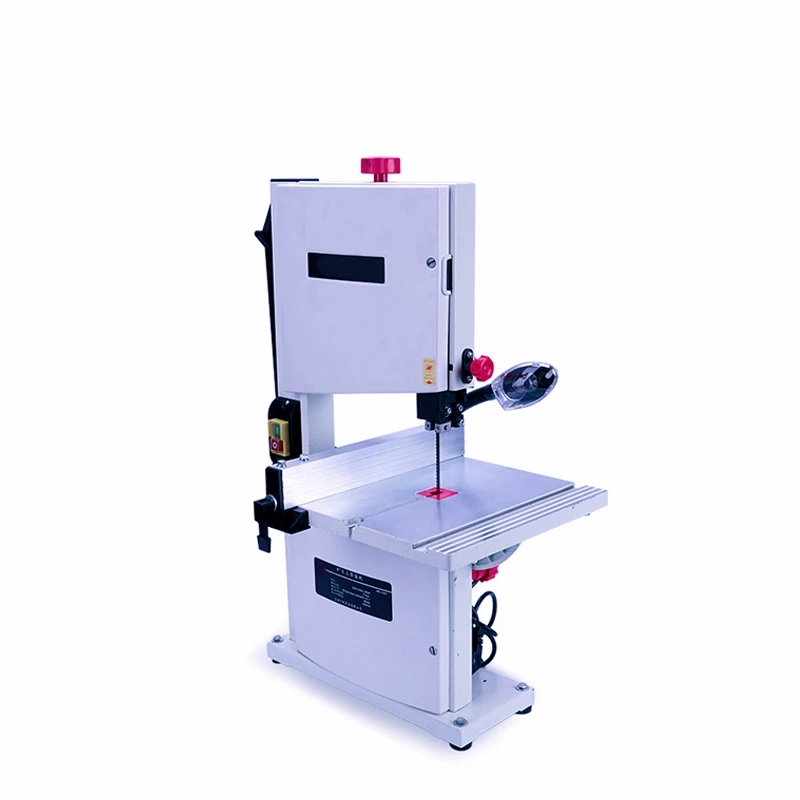

Полуавтоматическая Вертикальная ленточная пила для резки металла

Адаптер переключатель Монтажная пластина для Осмо мобильный GOPRO Hero 5

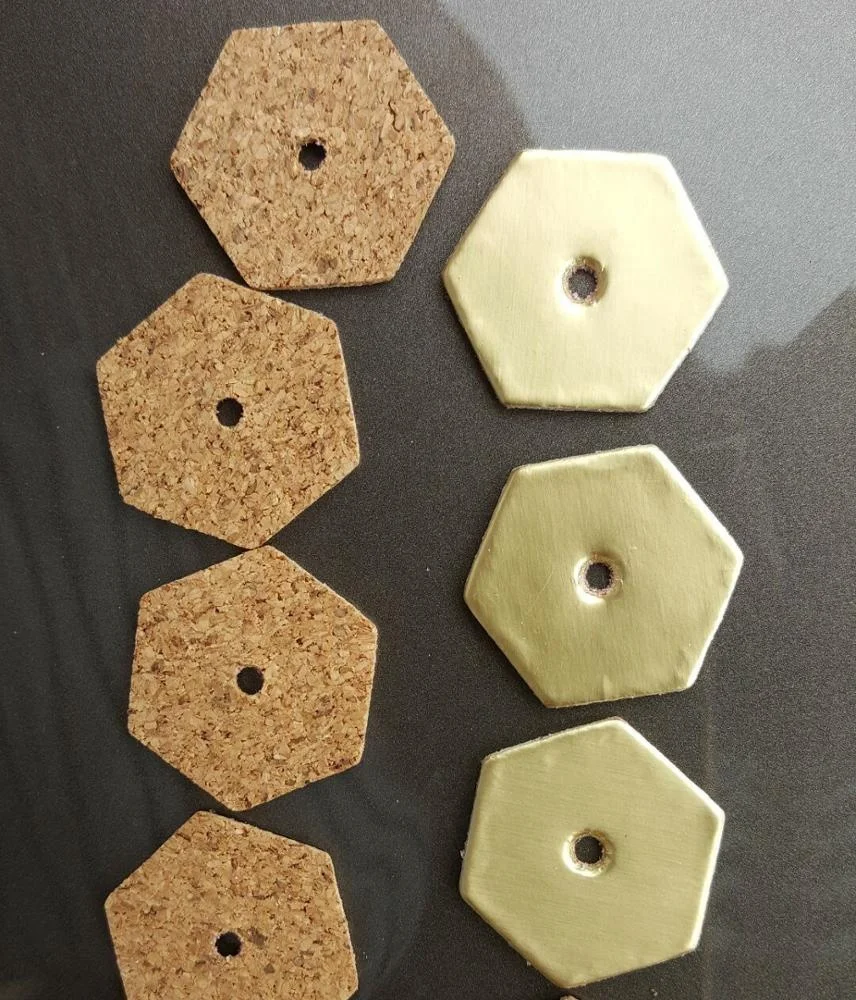

Плавающая пробковая свеча, фитили и пробковый дизайн под заказ

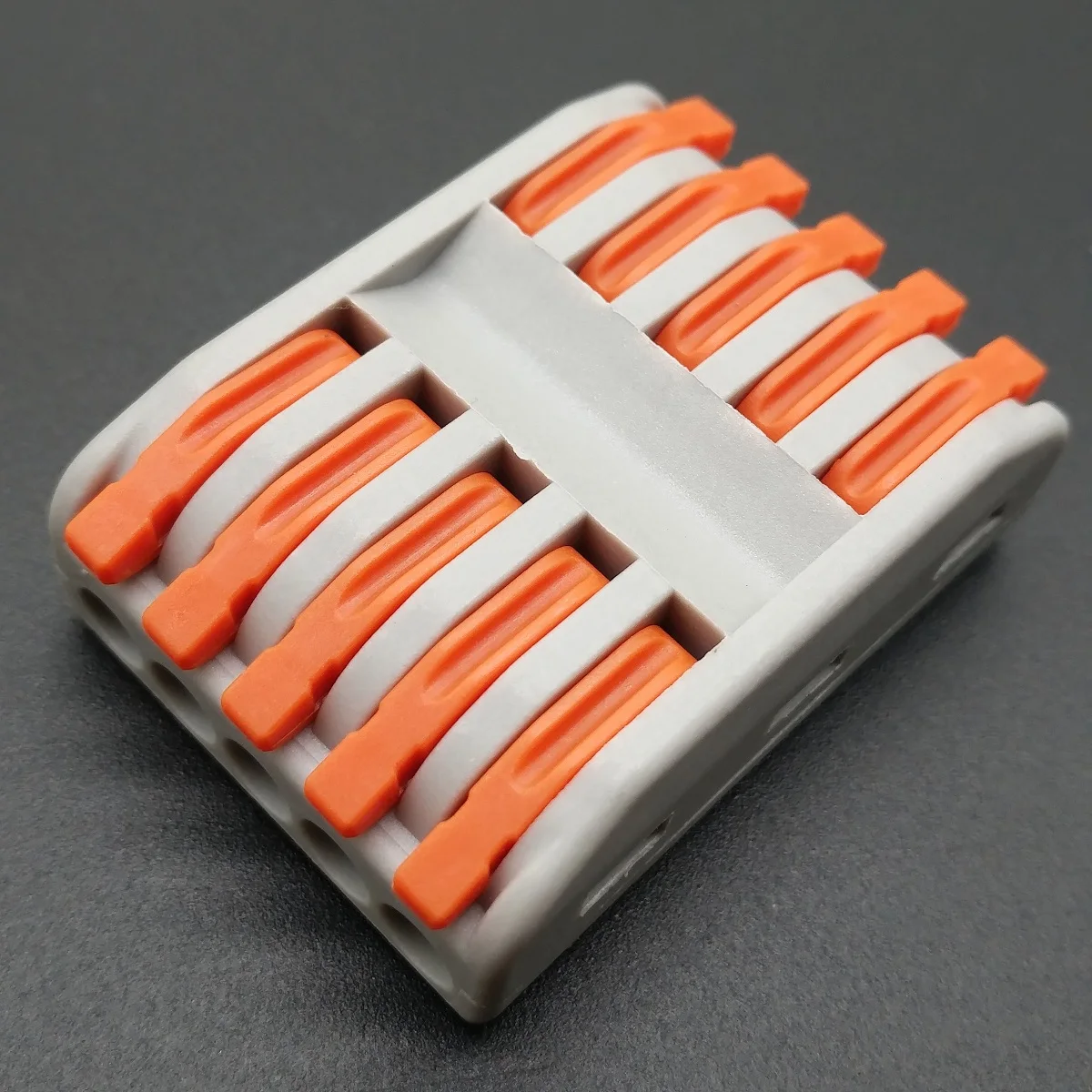

Электрическое осветительное оборудование, распределительная коробка, компактный соединительный провод, Клеммная колодка, соединители

ZHEJIAGN LINGBEN маленький портативный бензиновый мини-генератор 650 Вт, толовый генератор с CE

Пользовательские печатные тисненые бумажные косметические наборы волос парик подарок жесткий картон роскошный ящик коробка с ручками

Новые поступления

Новинки товаров от производителей по оптовым ценам