Подвесная цепь микропористый трубчатый аэратор для пруда

- Категория: >>>

- Поставщик: Beihai Kaite Chemical Packing Co. Ltd.

Сохранить в закладки 1600346179431:

Описание и отзывы

Характеристики

Suspended chain movable aerator is a new type of tubular aeration aerator, it is the core equipment of improved A/O process (activated sludge biochemical process). Compared with ordinary microporous aeration equipment, the oxygen increasing efficiency and power efficiency of the device are improved. And easy to install, during the maintenance, it does not affect the normal operation, does not need to stop the gas supply and no water release, and in the transformation, does not need to replace the damaged aerator, practical and reliable. Which can be applied effectively to any part of the aeration tank, with uniform oxygen supply and low energy consumption.

Product Material

1. Aerator membrane: EPDM membrane or silicone rubber.

2. Suspension link tube: high strength polyvinyl chloride (PVC) pipe.

3. Aerator support tube: ABS or PVC.

4. Float tube: UV-resistant HDPE pipe.

5. Fasteners: stainless steel.

Product Features

1. Using EPDM or silicone membrane, completely solve easy tearing and short life of rubber membrane.

2. Strong ability of anti-collision, not easily damaged.

3. Built-in check valve, completely solve the backwater phenomenon.

4. Float tube with anti-UV materials as whole welding, completely solve the leakage phenomenon, and long service life.

5. All corrosion-resistant material.

1. Easy fitting into new installations.

2. Easy retrofitting into existing installations.

3. High oxygen transfer efficiency.

4. Low operating costs.

5. Low maintenance costs.

1. Suspended chain movable aerator is a new type of energy saving aeration equipment in industrial wastewater and municipal sewage biochemical treatment project.

2. Suspended chain movable aerator can be used to modify the aerator with low operating efficiency or frequent clogging, so as to improve the oxygen increasing ability and agitation effect.

Model | Double pipe suspension chain | Three pipe suspension chain | Four pipe suspension chain | Eight pipe suspension chain |

Service area (m2/set) | 5-10 | 7-15 | 10-20 | 20-40 |

Membrane thickness (mm) | 1.7-2 | 1.7-2 | 1.7-2 | 1.7-2 |

Working air flow (m3/set) | 10-20 | 15-30 | 20-40 | 40-80 |

Micropore density (piece/set) | 28,000 | 42,000 | 56,000 | 112,000 |

Tearing resistance (Right angle type) ( KN/m) | 60-68 | 60-68 | 60-68 | 60-68 |

Resistance loss (Pa) | 2000-3000 | 2000-3000 | 2000-3000 | 2000-3000 |

Pore length (mm) | 0.8-2 | 0.8-2 | 0.8-2 | 0.8-2 |

Membrane diameter (mm) | 65-69 | 65-69 | 65-69 | 65-69 |

Dissolved oxygen effect (Clear water) (PPM) | >6 | >6 | >6 | >6 |

Pressure resistance strength (Kg/cm2) | >3 | >3 | >3 | >3 |

Theoretic dynamic efficiency (KgO2/Kw.h) | 6.5 | 6.5 | 6.5 | 6.5 |

Oxygen utilization ratio (%) | >35 | >35 | >35 | >35 |

Похожие товары

Resun WP-10000 морской воды и пресной воды аквариум для рыбок амфибия погружной насос

Промышленное оборудование, резервуар для хранения воды FRP, резервуар для системы очистки воды

Отличный кислородный аэратор для пруда рыбы/солнечный аэратор для пруда рыбы/аэратор для колеса с дизельным двигателем

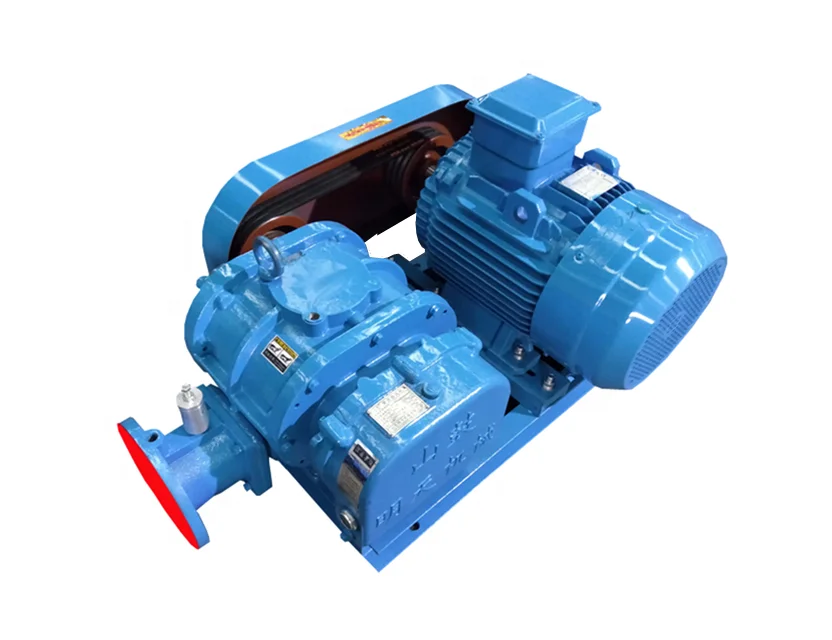

Shangu бренд 0.6-184m3/мин, аэратор для аквариумной рыболовной фермы, воздуходувка для корней, оборудование для аэрации пруда в соответствии с мадридским протоколом

Водяной охлаждающий аэратор 1,5 кВт с волнообразным перенапряжением для рыбы и креветок, сельскохозяйственное оборудование для пруда для аквакультуры

4 лопастных колесного аэратора (3 фазы), аэраторное оборудование для сельского хозяйства, рыбы, 2hp аэратор для аквакультуры

Аэратор для рыбного пруда, оборудование для аквакультуры, аэратор для пруда

Новые поступления

Новинки товаров от производителей по оптовым ценам