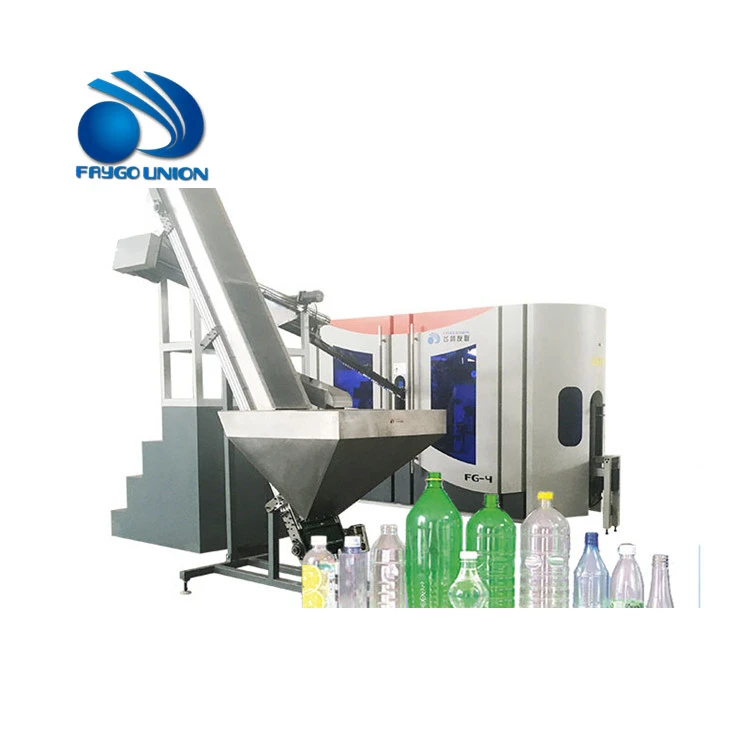

Faygo union ротационная выдувная формовочная машина для пэт бутылок воды

- Категория: >>>

- Поставщик: Jiangsu Faygo Union Machinery Co. Ltd.

Сохранить в закладки 1600347276698:

Описание и отзывы

Характеристики

production Introduction

Expert in energy saving and high speed blowing machine

2.In view of this situation, Faygo Union Machinery developed China first high speed linear blowing machine: FG4. The single mold speed can reach 2000 BPH. FG4 has 4 cavities, production capacity is 8000BPH. It is developed completely independently, has our own intellectual property rights, and has obtained more than 13 national patents.

3.FG4 is completely new generation of linear machine, distinguished by its high speed, low power and low compressed air

comsumption, featured by the excellent structure design, small space occupation, less noise and excellent stability, meanwhile conforms to national beverage sanitary standards. It symbolizes the highest level of national linear blowing machine. It is the ideal bottle making equipment for beverage enterprises.

3.FG4 is completely new generation of linear machine, distinguished by its high speed, low power and low compressed air

comsumption, featured by the excellent structure design, small space occupation, less noise and excellent stability, meanwhile conforms to national beverage sanitary standards. It symbolizes the highest level of national linear blowing machine. It is the ideal bottle making equipment for beverage enterprises.

In our blower,preform distance is only 38mm,with fewer lamps,you can heat more preforms

2.Up to 20 mins change mold

What if you change mold like open & close a drawer?

With our special quick-mold-change design,mold can find position itself, and be changed within 20 minutes.

3.Up to 30% less by air

This machine is fully driven by servo motor,no need low pressure air

We also decrease the dead volume in the blowing station to reduce high pressure air consumption

4.Up to 80% less maintain cost

Changing new air cylinders and seal rings is main maintain cost in blower

We adopt servo motors, It is more reliable and almost no need maintain cost

Detail

Heater distance in the heating oven is minimized to 38.1mm, compared with the conventional heating oven, it saves more than 30% electricity consumption.

Equipped with the air cycling system and redundant heat discharge system, it ensures the constant temperature in the heating zone.

Equipped with the air cycling system and redundant heat discharge system, it ensures the constant temperature in the heating zone.

To change mold only need 30 minutes.

Equipped with remote monitoring system, engineers in China headquarter can check the data collected and sent by the PLC anytime with the mobile, feedback will be informed to the client' s site if something abnormal,give the machine 24 hours' baby care in the cradle.

The unique cam linking system integrates mold-opening, mold-locking and bottom mold-elevating in one movement, equipped with high speed servo driving system which greatly shortens the blowing cycle and accelerates the speed.

Our Advantages

1.Our new design PET bottle machine with below high-tech can save 130000kwh electric one year for customer compare with normal

linear 4 cavity blowing machine. 2.Our PET bottle blowing machine is a completely new generation of linear blowing machine, distinguished by its high speed, low

power and low compressed air consumption, featured by the excellent structure design, small space occupation, less noise and high

stability, meanwhile conforms to national beverage sanitary standards.

3.This machine symbolizes the highest level of national linear blowing machines. It is the ideal bottle making equipment for medium

power and low compressed air consumption, featured by the excellent structure design, small space occupation, less noise and high

stability, meanwhile conforms to national beverage sanitary standards.

3.This machine symbolizes the highest level of national linear blowing machines. It is the ideal bottle making equipment for medium

and large enterprises.

Each Year, We Guarantee Your Bottle Making Factory:

1) Output increased by 50%2) Waste bottle rate below 0.3%

3) 20,000USD saved by power consumption

4) blowing machine maintain cost below 800USD

Technical Parameter

PET BLOWING MACHINEModel | FG4 | FG6 | FG8 |

Cavity number | 4 | 6 | 8 |

Operation Speed (bph) | 8000 | 12000 | 16000 |

Max volume(ml) | 2000 | 2000 | 750 |

Heating oven Power (kw) | 22 | 26 | 38 |

Total installation power (kw) | 51 | 51 | 97 |

Air consumption (m3/min) | 4 | 6 | 8 |

Machine weight (kg) | 3500 | 4000 | 4500 |

Application

Delivery: 30-45 working days

Port: Shanghai port

related peoudct

Three in one filling machine

Compressor

bottle cutting machine

Capping machine

Blow can spin

Injection molding machine

Customer Photos

Our company

Plastic profile/pheet extrusion lineWood plastic composite extrusion line

Plastic pipe extrusion line Plastic recycling pruduction line

Plastic pipe extrusion line Plastic recycling pruduction line

Faygo is a new high-tech entreprise covering 20000㎡, which specializes in reserching and manufacturing blowing blowing machines.

2.PRODUCTS

PVC/HDPE/PP-R pipe extrusion line, plastic sheet production line and relative auxiliary machines,PE film/PETbottles recycling line and pelletizing line.

3.MARKETING

Our products have been exported to Middle East, Southeast Asia, South America and Europe etc. We've received universal

confirmation and trust from our customers.

4.IDEA

Making good machine, Bing good person.

2.PRODUCTS

PVC/HDPE/PP-R pipe extrusion line, plastic sheet production line and relative auxiliary machines,PE film/PETbottles recycling line and pelletizing line.

3.MARKETING

Our products have been exported to Middle East, Southeast Asia, South America and Europe etc. We've received universal

confirmation and trust from our customers.

4.IDEA

Making good machine, Bing good person.

OUR SERVICE

1.High-quality equipment and highly competitive market prices can bring you more profits.

2.We have a one-year warranty and can provide long-term technical support.

24hours one line after sale service, all life technical support

3.Years of experience in the reserch of plastic extruders enable us to solve most of the problems and improve efficiency.

4.Send Your Inquire Details In The Below Click "Send" Now!

3.Years of experience in the reserch of plastic extruders enable us to solve most of the problems and improve efficiency.

4.Send Your Inquire Details In The Below Click "Send" Now!

RFQ

Q:Are you machinery factory or trading company?

A:We are machinery factory

Q:If we have very special request for the production line,could you help me to do the design?

A:Experienced mechanical designer customized-design provided.

Q:Installation and stuff training available from you?

A:Yes, our engineers will guide machine installation and train your workers.

Q:How can we visit your company and machines?

A:We are located in Zhangjiagang City which is about 2.5 hours nearby Shanghai Airport.If customer want to visit our factory,we will pick up you at the airport.

Q:What`s the payment method?

A: T/T, L/C,Western Union,etc

Q:How long is the warranty?

A:1 year

Q:How long is the delivery time?

A:Under normal conditions, products are delivered within 45 working days.

Q:How can I know the stauts of my order?

A:We will send you photos and videos of your order at different satge in time and keep you informed of the latest information.

A:We are machinery factory

Q:If we have very special request for the production line,could you help me to do the design?

A:Experienced mechanical designer customized-design provided.

Q:Installation and stuff training available from you?

A:Yes, our engineers will guide machine installation and train your workers.

Q:How can we visit your company and machines?

A:We are located in Zhangjiagang City which is about 2.5 hours nearby Shanghai Airport.If customer want to visit our factory,we will pick up you at the airport.

Q:What`s the payment method?

A: T/T, L/C,Western Union,etc

Q:How long is the warranty?

A:1 year

Q:How long is the delivery time?

A:Under normal conditions, products are delivered within 45 working days.

Q:How can I know the stauts of my order?

A:We will send you photos and videos of your order at different satge in time and keep you informed of the latest information.

Похожие товары

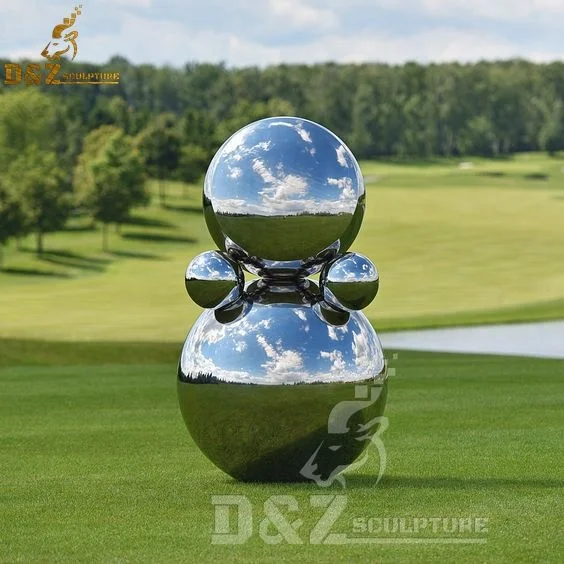

Абстрактная Металлическая скульптура разной формы в полированной хромированной серебряной декоративной скульптуре

C18150 лучший медного хрома циркония бронзовые скульптуры

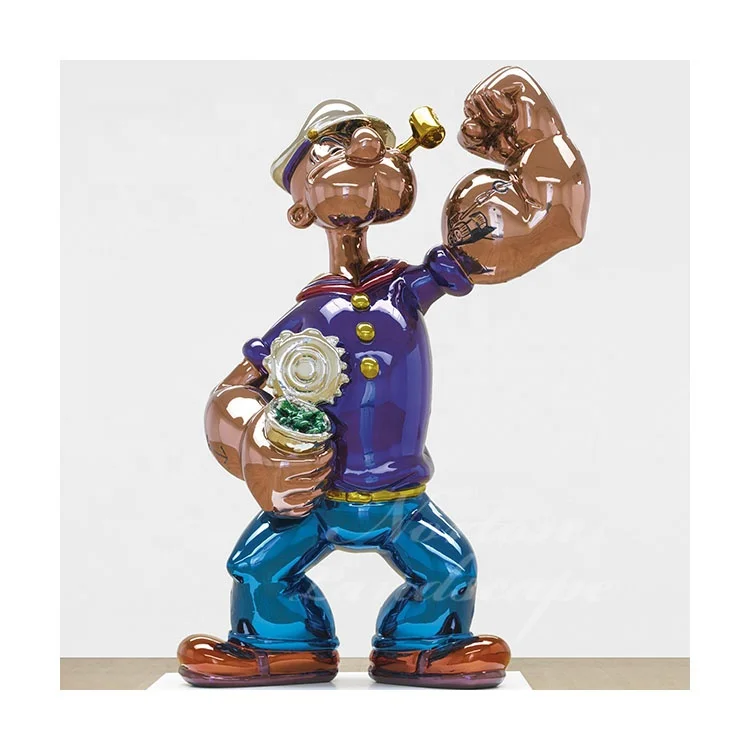

Стекловолоконная Гальваническая хромированная блестящая цветная статуя Popeye для продажи

Уличное украшение, металлическое зеркало, полированная хромированная скульптура из нержавеющей стали Venus

1 950,00 $

Профессиональная цветная хромированная фабрика Смола Современная Художественная Скульптура

158,00 $ - 168,00 $

Большая уличная современная статуя из нержавеющей стали, скульптура в форме шара, абстрактная сферическая скульптура

Поп-арт Лоренсо Квинн художественная тема находка любви бронза касание рук скульптура

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $