Магнитный сепаратор высокой интенсивности с четырьмя роликами 15000 Гаусс Сухой Тип отдельный оловянный циркон ильменит руда тяжелый минеральный железный песок

- Категория: >>>

- Поставщик: Ganzhou Gelin Mining Machinery Co. Ltd.Ganzhou Ltd.

Сохранить в закладки 1600353601941:

Описание и отзывы

Характеристики

Products Description

Beach black sand dry type separator ilmenite ore magnetic separator

Our factory produces one roller, two rollers, three rollers, four rollers dry type high intensity magnetic separator and low intensity magnetic separator, magnetic field intensity from 800 gauss to 20000 gauss. The high gradient magnetic separator is a strong magnetic separator for the screening of weak magnetic minerals the dry magnetic separators are widely used for separate magnetic iron ore,Tin ore, ilmenite, titanium ore, hematile, manganese, cobalt, cassiterite, coltan,tantalum, niobium, zircon sand, beach black sands, Monazite ore, Rutile ore,silica purify sand and so on.

1). Four rollers high intensity dry type magnetic separator (Below Pictures)

Capacity:2-5 tons per hour;

Feeder hopper on the top of the machine;

Four drums/rollers:

First drum size: diameter 440 mm* length 1100 mm, magnetic field intensity:1000 gauss-1500 gauss;

Second drum size:diameter 440 mm* length 1100 mm, magnetic field intensity:5000 gauss-7000 gauss;

Third drum size:diameter 440 mm* length 1100 mm, magnetic field intensity:8000 gauss-10000 gauss;

Fourth roller size:diameter 220 mm* length 1100 mm, magnetic field intensity:15000 gauss;

Material: steel for the whole machine frame;

Frequency conversion motors;

AC Inverter Controller to adjust the speed variation of each rollers/drums;

Electric control pannel box to control the machine working;

Feeder hopper on the top of the machine;

Four drums/rollers:

First drum size: diameter 440 mm* length 1100 mm, magnetic field intensity:1000 gauss-1500 gauss;

Second drum size:diameter 440 mm* length 1100 mm, magnetic field intensity:5000 gauss-7000 gauss;

Third drum size:diameter 440 mm* length 1100 mm, magnetic field intensity:8000 gauss-10000 gauss;

Fourth roller size:diameter 220 mm* length 1100 mm, magnetic field intensity:15000 gauss;

Material: steel for the whole machine frame;

Frequency conversion motors;

AC Inverter Controller to adjust the speed variation of each rollers/drums;

Electric control pannel box to control the machine working;

Usage: it is used for separate Tin ore(cassiterite), Zircon ore, Magnetic iron ore, Ilmenite ore, Monazite ore, Rutile ore, silica sand, weak magnetic ore and so on.

2). Three rollers high intensity dry type magnetic separator (see below pictures)

Capacity:1-2 tons per hour;

Feeder hopper on the top of the machine;

Three rollers:

First roller size: diameter 160 mm* length 1200 mm, magnetic field intensity:1200 gauss;

Second roller size:diameter 390 mm* length 1200 mm, magnetic field intensity:8000 gauss;

Third roller size:diameter 160 mm* length 1200 mm, magnetic field intensity:13000 gauss-15000 gauss;

Material: steel for the whole machine frame;

Adjust speed motors;

Electromagnetic speed regulation to adjust the roller speed;

Feeder hopper on the top of the machine;

Three rollers:

First roller size: diameter 160 mm* length 1200 mm, magnetic field intensity:1200 gauss;

Second roller size:diameter 390 mm* length 1200 mm, magnetic field intensity:8000 gauss;

Third roller size:diameter 160 mm* length 1200 mm, magnetic field intensity:13000 gauss-15000 gauss;

Material: steel for the whole machine frame;

Adjust speed motors;

Electromagnetic speed regulation to adjust the roller speed;

Dimension:1700*1500*2280mm;

3). Two rollers high intensity magnetic separator (see below pictures)

Capacity:1-2 tons per hour;

Feeder hopper on the top of the machine;

Two rollers:

First roller size: diameter 160 mm* length 1200 mm, magnetic field intensity:13000 gauss;

Second roller size:diameter 160 mm* length 1200 mm, magnetic field intensity:13000 gauss;

Material: steel for the whole machine frame;

Adjust speed motors;

Electromagnetic speed regulation to adjust the roller speed;

Dimension:1700*1400*2250mm;

Capacity:1-2 tons per hour;

Feeder hopper on the top of the machine;

Two rollers:

First roller size: diameter 160 mm* length 1200 mm, magnetic field intensity:13000 gauss;

Second roller size:diameter 160 mm* length 1200 mm, magnetic field intensity:13000 gauss;

Material: steel for the whole machine frame;

Adjust speed motors;

Electromagnetic speed regulation to adjust the roller speed;

Dimension:1700*1400*2250mm;

4). One roller low&high intensity magnetic separator (see below pictures)

Capacity:10-20 tons per hour;

Feeder hopper on the top of the machine;

One roller:

Roller size: diameter 400mm* length 1800mm, magnetic field intensity:1200 gauss;

Material: steel for the whole machine frame;

Adjust speed motors;

Electromagnetic speed regulation to adjust the roller speed;

Capacity:10-20 tons per hour;

Feeder hopper on the top of the machine;

One roller:

Roller size: diameter 400mm* length 1800mm, magnetic field intensity:1200 gauss;

Material: steel for the whole machine frame;

Adjust speed motors;

Electromagnetic speed regulation to adjust the roller speed;

Application&Successful Case

Packing & Delivery

Packing

Normally the machines are taken apart before delivery and are packed by suitable packing ways, the packing ways are as below:

1. Nude packing.

2. Bundle packing.

3. Grass rope packing.

4. Water proof packing.

5. Wooden pallets packing.

6.Wooden box or carton box packing.

Delivery

Usually the equipments are delivered aboard by tracks,trains,or container(sea transportation). and some spare parts or very small goods also support to send by express, our company have built good relationships with large cargo agent and shipping companies which guarantee our products delivered safely and promptly.

Normally the machines are taken apart before delivery and are packed by suitable packing ways, the packing ways are as below:

1. Nude packing.

2. Bundle packing.

3. Grass rope packing.

4. Water proof packing.

5. Wooden pallets packing.

6.Wooden box or carton box packing.

Delivery

Usually the equipments are delivered aboard by tracks,trains,or container(sea transportation). and some spare parts or very small goods also support to send by express, our company have built good relationships with large cargo agent and shipping companies which guarantee our products delivered safely and promptly.

Sea Transportation | Air Transportation |

20GP/40HQ container:Goods without overlength, overheight and overweight; | For small size light weight cargo |

FR(flat rack) container: Large equipments with overlength,overheight | |

Less than container load (LCL): Goods without loading in full container |

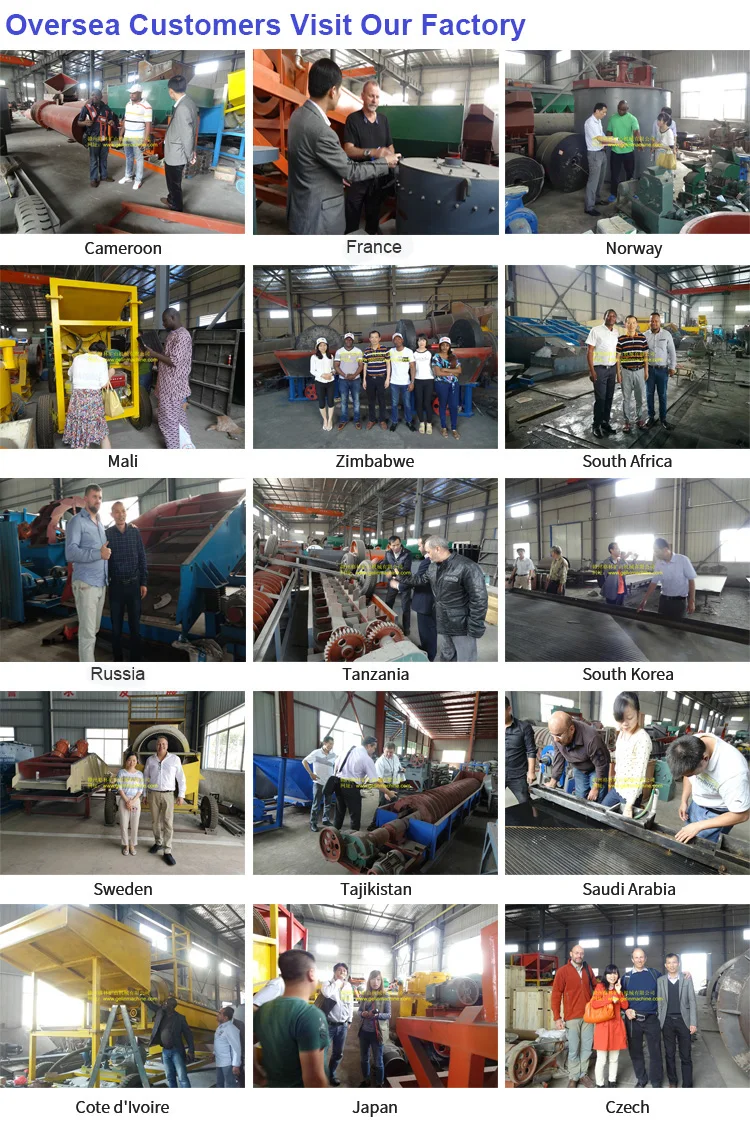

About Company

Ganzhou Gelin Mining Machinery Co., Ltd is an over 30 years professional manufacturer and exporter of mining machinery for crushing, screening, grinding, flotation, separation etc. in China. Gelin have a complete service system which can provide customer full service in mining field and after sales service.By now, Gelin’s equipments and services are exported to over 60 countries,include America, Russia, India, Africa, Brazil, Chile,South Africa,Zambia etc.

Sincerely welcome customers to visit our factory.

Our Services

One Stop solution for beneficiation plant service:

1.Engineering consulting available,it makes clients have a comprehensive understanding of beneficiation plant,including mine value,useful elements,mineral processing technology,plant scale,essential equipments,etc.

3.After reaching agreement with client,we start to engineering design,including planning,investigation,data collection, project evaluation etc. and then comes up with design scheme of beneficiation plant construction and working drawings.

1.Engineering consulting available,it makes clients have a comprehensive understanding of beneficiation plant,including mine value,useful elements,mineral processing technology,plant scale,essential equipments,etc.

2.Arrange mineral beneficiation experiment after received the material sample and beneficiation test report will be done after test.

3.After reaching agreement with client,we start to engineering design,including planning,investigation,data collection, project evaluation etc. and then comes up with design scheme of beneficiation plant construction and working drawings.

4.Manufacturing the necessary equipments and arrange the shipment.

5.Complete services for Installation and commissioning and technical training(operating training,common problem solving training).

After-sale Service

Regularly visit customers to provide after- sale technical supports and to solve problems of beneficiation plant. For equipments supplied,we could provide one-year warranty and provide spare parts with preferential price in the long term and be responsible for any problems with the them.

FAQ

Q: Are you a trading company or a factory?

A: We are a factory at Shicheng county with 110 workers,6 workshops covered 17,000㎡ and office covered 2,500㎡. Welcome to visit our factory at anytime.\t

A: We are a factory at Shicheng county with 110 workers,6 workshops covered 17,000㎡ and office covered 2,500㎡. Welcome to visit our factory at anytime.\t

Q: What is your payment terms?

A: By TT(Telegraphic Transfer), 100% or 40% Deposit before production and 60% balance payment will be paid off after sending product pictures and before loading from factory.

A: By TT(Telegraphic Transfer), 100% or 40% Deposit before production and 60% balance payment will be paid off after sending product pictures and before loading from factory.

Q: How long is the guarantee period of your products?

A: The guarantee period is 1-2 years, pls ask staff for more details. And we will supply lifelong technical support service and the spare parts at lowest cost.

Q: Is it possible to produce customized products ?

A: Yes, most of our products are produced as required.

A: Yes, most of our products are produced as required.

Q: Is it possible to provide sample for your factory to do ore-dressing experiment?

A: Yes, engineering consulting is available and we’d like to arrange mineral beneficiation experiment after received your sample and provide the test report.

A: Yes, engineering consulting is available and we’d like to arrange mineral beneficiation experiment after received your sample and provide the test report.

For more details, please refer to our website: www.gelinmachinery.com

Related Products

Похожие товары

Флотационная ячейка медная руда установка для переработки кислоты промывочная машина/Горный танк

4 000,00-4 920,00 $

Горячая распродажа Мобильная Золотая стиральная машина Золотое стиральное оборудование для Cameroon

13 150,00-21 000,00 $

Флотационная Машина для концентрации литиевых оловянных танталовых руд

800,00 $

GUOTE горнодобывающая Автоматическая Машина Для шлифовальной машины вертикальный воздушный классификатор

1 008,00 $

Полный комплект оборудования для производства золотистой руды машина Флотационной горной

Оборудование для промывки и экрана

80 000,00 $

Оптовая цена оборудование для минеральной обработки винтовая шайба двойная Одиночная Спиральная Шайба спиральный классификатор литиевой руды

3 700,00-3 980,00 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $