2021 горячая Распродажа longhua LH1050D jigпилы автоматическая машина для глубокого тиснения и высечки pdf

- Категория: >>>

- Поставщик: Wenzhou Longhua Machinery Co. Ltd.

Сохранить в закладки 1600358812084:

Описание и отзывы

Характеристики

Product Overview

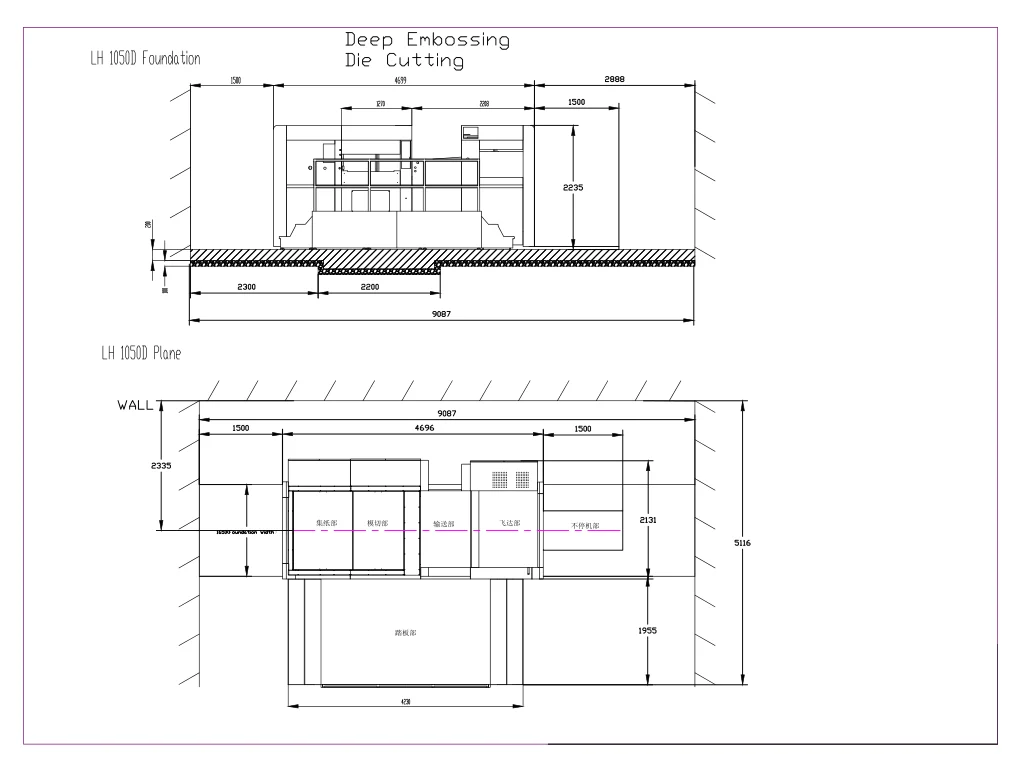

Fully automatic Longhua LH1050D flatbed embossing die cutting & creasing machine

Zhejiang Longhua Machinery Co., Ltd in order to meet various request of printing and

packing market, we designed 1050D Automatic Deep Embossing Die Cutting Machine, which is the greatest research and development and

manufacturing of new equipment with a higher degree of intelligence.

This machine adopts numerous advanced pneumatic and servo driving processing technology from abroad. After the strict assembly

quality control, it has advantage of simple operation and safe reliable.

It could deep embossing, creasing and die cutting after printing products, such as more than 80g/m2 paper, cardboard, corrugated

paper below 4mm, pasting paper, laminating paper and so on.

Good quality and design makes machine work stably and safety when machine’s speed reach 7500 sheets/h. This machine will provide

you to enjoy the comfortable operation and faster return on investment.

packing market, we designed 1050D Automatic Deep Embossing Die Cutting Machine, which is the greatest research and development and

manufacturing of new equipment with a higher degree of intelligence.

This machine adopts numerous advanced pneumatic and servo driving processing technology from abroad. After the strict assembly

quality control, it has advantage of simple operation and safe reliable.

It could deep embossing, creasing and die cutting after printing products, such as more than 80g/m2 paper, cardboard, corrugated

paper below 4mm, pasting paper, laminating paper and so on.

Good quality and design makes machine work stably and safety when machine’s speed reach 7500 sheets/h. This machine will provide

you to enjoy the comfortable operation and faster return on investment.

FEATURES AT A GLANCE

1. Feeder/Feeding Section

The design of stacker preparatory stage was improved, it could use prepared car sheet piling. Also could use ordinary hydraulic

car sheet piling to stacker directly. The machine has four suction nozzles and four sending nozzles in feeder, ensure feed

smoothly. Adopt import screw air-blowing device, it could make the sheet send smoothly.

car sheet piling to stacker directly. The machine has four suction nozzles and four sending nozzles in feeder, ensure feed

smoothly. Adopt import screw air-blowing device, it could make the sheet send smoothly.

2.Feeding Positioning Section

The incline-type paper moving table top is more suitable to high-speed thin paper and

location. Side location adopt dual purpose side device with pull guide and push guide, accounting to paper choose, it makes switch

easier. It could switch front rise position arriving reduction of speed device, it is benefit of thin paper’s location.

location. Side location adopt dual purpose side device with pull guide and push guide, accounting to paper choose, it makes switch

easier. It could switch front rise position arriving reduction of speed device, it is benefit of thin paper’s location.

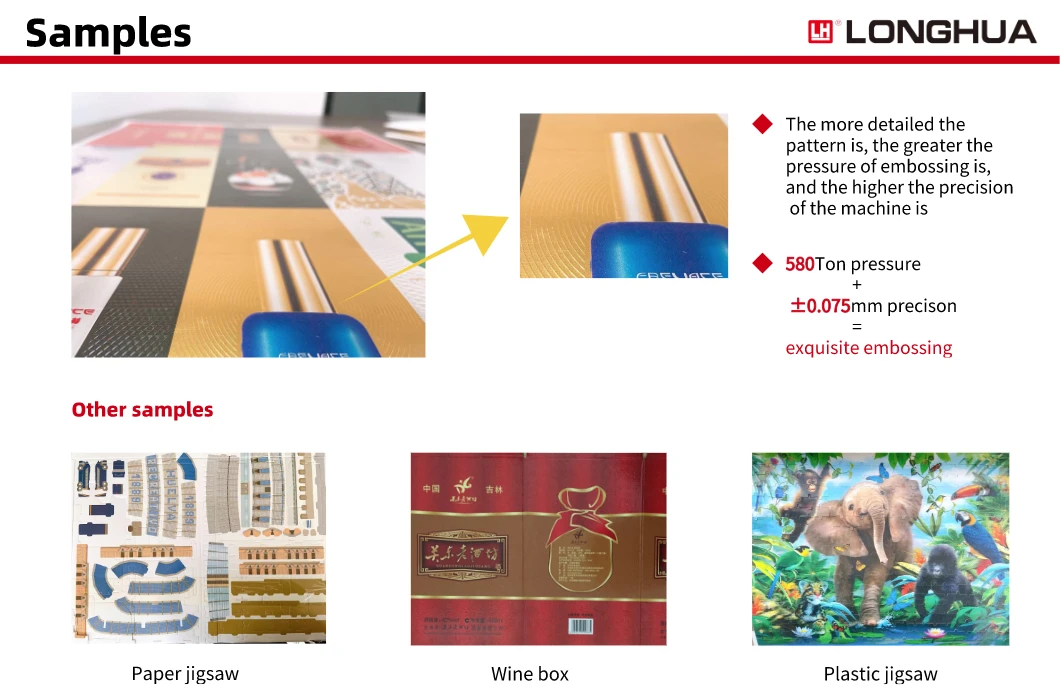

3.Deep Embossing

deep embossing plate(copper)

die cutting plate

12 heated temperature areas in die cutting platform, they have timing penumatic temperature controller function, each area can be

controlled separately. It adopts hot embossing, hot bumps, hot indentation and so on. Hot press honeycomb is made by high strength

heat-resistant material, it will be not transformation in high temperature. Hot press honeycomb knife and die cutting knife could

be changed, so it achieves the switch of hot press function and die cutting function.

controlled separately. It adopts hot embossing, hot bumps, hot indentation and so on. Hot press honeycomb is made by high strength

heat-resistant material, it will be not transformation in high temperature. Hot press honeycomb knife and die cutting knife could

be changed, so it achieves the switch of hot press function and die cutting function.

4. Thick wall

Thicken wall could stress-tolerant 1000 ton, the embossing is clearer, the effect is better.

The whole wall is made of nodular cast iron, which is better than regular steel.

The whole wall is made of nodular cast iron, which is better than regular steel.

5. 12 temperature controll section

The 12 independent heating areas are controlled by a PID system,which researched by our

department. This system could control the temperature stably, ensure the temperature uniform in whole heating system, quick

response, it could adapt complex electrochemical aluminum transfer effect.

department. This system could control the temperature stably, ensure the temperature uniform in whole heating system, quick

response, it could adapt complex electrochemical aluminum transfer effect.

4. Delivery Section

Delivery section add tester into security system. It is equipped with inset counter. Using subsection could adjust brush and sheet

air-blowing device, so the finished product of delivery section could product stably. Gripper drive train expanded buffer device.

air-blowing device, so the finished product of delivery section could product stably. Gripper drive train expanded buffer device.

PRODUCT SPECIFICATIONS

No | Item | Data |

1 | Max. Sheet Size | 1050×750mm |

2 | Min. Sheet Size | 400×360mm |

3 | Max. Cutting Range | 1040×720mm |

4 | Inner Chase Size | 1080×745mm |

5 | Die Cutting Steel Plate Size | 1080×736mm |

6 | Paper Thickness | 80-2000 g/m2 Cardboard Corrugated paper≤4mm |

7 | Plastic Range | 0.1-2.0mm |

8 | Min. Grabbing-sheet Width | 9mm |

9 | Max. Mechanical Speed | 7500 sheets/h |

10 | Max. Die Cutting Pressure | 580T |

11 | Max. Feeding Pile Height | 1350mm |

12 | Max. Delivery Pile Height | 1200mm |

13 | Total Weight | 18.9T |

14 | Dimensions | 6300×4200×2100mm |

15 | Heating system | 12 heating areas, 40°C-180°C adjustable |

16 | Total Power | 20kw |

17 | Full Load Power | 42kw |

18 | Voltage Requirements | 380V 50Hz |

19 | Air compressor | 0.8Mpa, 0.36m3/min, 3kw |

FAQ

Q1: Do you have stock products to sell?

We manufacture machines in batch. So most of machines have in stock, please check with us before ordering.

Q2: How about installation and training?

Installation and training: If purchaser's engineer travels at own cost to China, free training session. If engineer sent to

purchaser's factory, all travel cost paid by purchaser.

Q3: How about warranty?

Warranty period: 12 months from the shipping date of machine. Warranty will be not valid if machine subject to misuse or

accidental damage or operator's error. During the valid time, we will supply spare parts. If you have any other questions, please

contact us and we will reply you through product's photos and videos to make every detail clear.

Q4:What is your payment? T/T.30% deposit, 70% balance before delivery.

L/C. 100% at sight.

T/T and L/C, 30% TT deposit, 70% L/C.

We manufacture machines in batch. So most of machines have in stock, please check with us before ordering.

Q2: How about installation and training?

Installation and training: If purchaser's engineer travels at own cost to China, free training session. If engineer sent to

purchaser's factory, all travel cost paid by purchaser.

Q3: How about warranty?

Warranty period: 12 months from the shipping date of machine. Warranty will be not valid if machine subject to misuse or

accidental damage or operator's error. During the valid time, we will supply spare parts. If you have any other questions, please

contact us and we will reply you through product's photos and videos to make every detail clear.

Q4:What is your payment? T/T.30% deposit, 70% balance before delivery.

L/C. 100% at sight.

T/T and L/C, 30% TT deposit, 70% L/C.

Samples

Why Choose Us

1.About the company

Wenzhou Longhua Machinery Co.,Ltd has a excellent reputation domestic and oversea, has exported to Europe,Africa ,America and

Southeast Asia ,and so on, due to our high level quality and intimate service.

The staffes of Longhua are creative,innovate,goodness,laborious,and capable,all of these excellent personalities make Longhua

develop and expend maket rapidly.

2.About the machine

Die cutting machine,foil stamping machine and embossing machine ,the classics of Longhua,which are in the industry leading level .

we have product these machines for tens of thousands times,so we have a skillful technology ,and 100% ensure the quality of

machines.

3.About the sevice

We provide one year after-sales sevice, including install,debug and the training. We are alway ready whenever customers need

us,and so pleasant to make friends with our clients.

Похожие товары

Промышленный полностью автоматический планшетный станок Longhua LH1060E для пластикового гофрированного картона

83 000,00 $

Longhua LH1050D планшетный автоматический лист подачи бумаги упаковки глубокое тиснение и высечки

110 000,00 $

Контактор Mitsubishi TH-N12KP, контактор подъемника mitsubishi

Paille biomasse брикет машина для изготовления древесных опилок к деревянной

Полностью автоматическая Longhua LH1050E планшетный штамповочный станок

86 000,00 $

Заменитель S-N50 Mitsubishi Лифт контактор S-T50 AC220V

Высокопроизводительная Вилка сцепления вала ford 16JS200T-1702057-1 для быстрой

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $