Бесшовная рельсовая тележка медная шина ПВХ корпус проводник кран подъемная система

- Категория: >>>

- Поставщик: Henan SINOCRANE GLOBAL Co. Ltd.

Сохранить в закладки 1600370818108:

Описание и отзывы

Характеристики

![]()

Seamless type rail trolley copper busbar PVC Housing Conductor Crane Hoist Busbar System

Seamless Busbar System

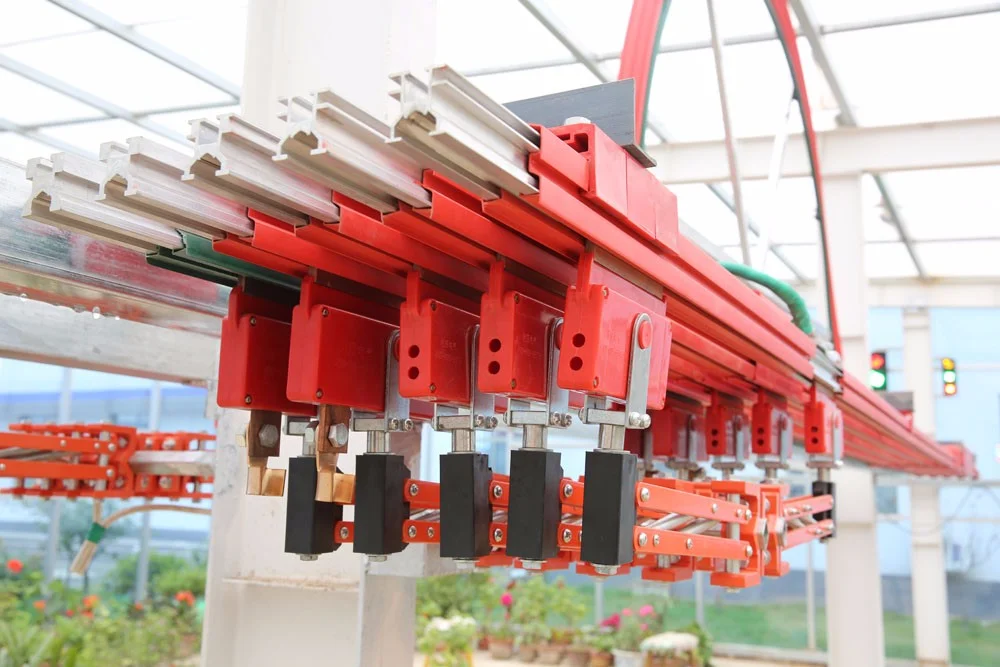

With FMS, unmanned factory, increasing the degree of automation of the device, the miniaturization of the conductor rail system, ease of installation, high-speed stability is extremely important. To meet the needs of market development, we has successfully developed the KM series seamless conductor rail system, the system has the following advantages, run smoothly, high speed, low noise, powered way arbitrariness.

With advanced technology, skillful manufacture and beautiful design, this crane conductor rail is suitable for machinery works, small size steel factory, low power hoisting, cranes, monorails, electric hoists, electric tools, lifting systems and wildly used in the Lifting industry.

Product Composition Structure

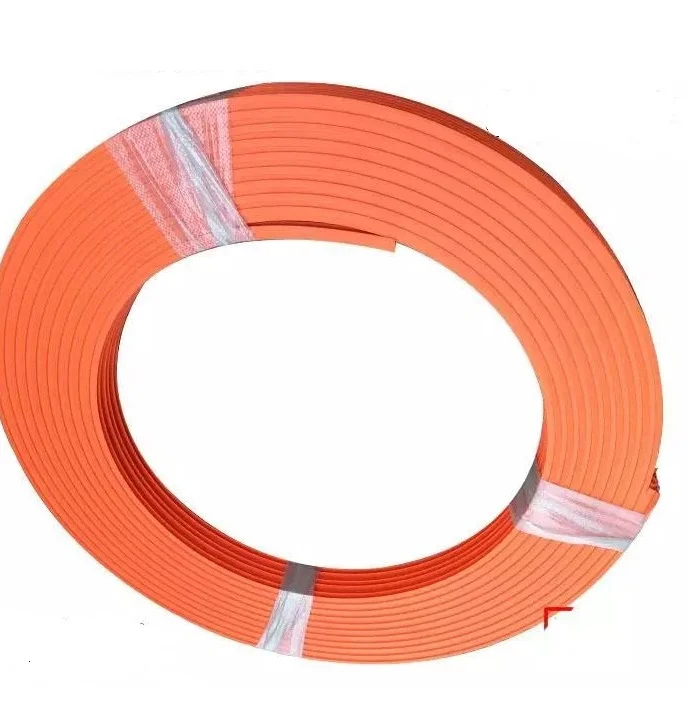

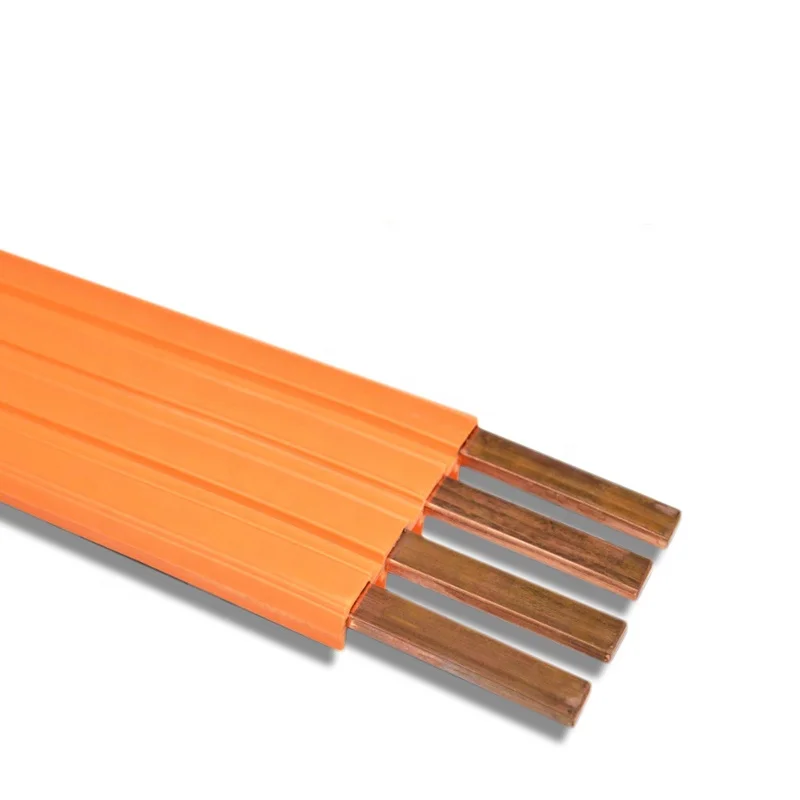

Seamless busbar is produced by advanced technology, there are three kinds of 3, 4, 6 pole, with the load matching, selection and utilization economically. Supply 1000m conductor without any joint, installation easily and quickly. Its conductor is anaerobic copper to convey current ,housing is PVC of high heat resistance ,voltage drop, never power cuts, good conductivity times, convenient installation, not easy to wear, easy to change, more convenient transportation, not easy to cause injury of sliding contact line, prolong service life.

Main Feature:

1. 99.99% Oxygen-free copper

2. No joint, continuous power supply

3. Small space, Low noise

4. Low voltage drop

5. Stable operation, fast speed, good conductivity and contact performance

6. Easy to install, replace and transport

7. Long service life

8. The minimum bend radius reaches 750mm

Main Components Structure

Parameters of matched power equipment

| Type | Poles | Conductor cross Section(mm²) | Max.current (A) | Weight (kg) |

| 761004 | 4 | 4×10mm² | 50A | 0.62 |

| 761504 | 4 | 3×15mm²+1×10mm² | 80A | 0.83 |

| 762004 | 4 | 3×20mm²+1×10mm² | 100A | 1.02 |

| 762504 | 4 | 3×25mm²+1×10mm² | 120A | 1.32 |

| 763504 | 4 | 3×35mm²+1×10mm² | 140A | 1.45 |

![]()

![]()

![]()

![]()

Design and Construction Rules

All the standards which are required for the busbar are the FEM standard, DIN standard and Chinese National standard.

Europe Main National Standards

-- 89/392/EEC standard (93/68/EEC)

-- 91/368/EEC standard

-- 73/23/CEE standard

-- "EMC" standard 89/336/EEC

-- EN 60204-1

-- EN 292 mechanical safety

-- ISO 2141

-- ISO 2766

International Standards

-- June 9, 1993 / Sept. 22, 1993 notice

-- July 29, 1992, 92-765, 92-766, 92-767 notice

-- DIN 5684

-- DIN 15400; DIN 15401

-- NFE 26-010

-- NFE 26-030

Technical Standards

-- FEM 9.511 Mechanical group

-- FEM 9.661 Hoisting and traveling components size and quality standard

-- FEM 9.671 Wire rope quality standard

-- FEM 9.681 Travel motor choice

-- FEM 9.682 Hoisting motor choice

-- FEM 9.755 Electric hoisting equipment

-- FEM 9.811 Electric crane standard

-- FEM 9.901 Hoisting components design reference

-- IEC 34-1 Traveling and allocation performance

-- IEC 34-5 Protection grade standard

-- IEC 947-5-1 Low voltage equipment

China Main National Standards

Design rules for busbar GB/T 3811-2008

Safety rules for lifting appliances GB 6067-2010

Common crane technical condition GB 7592-87

Seamless Busbar System

![]()

Notes: If you want to ask any questions about this product directly with us, pls click here !

Send your Inquiry Details in the Below, Click " Send " Now!

If you would like us to provide an accurate quote within 12 hours, please write down the following information:

1. Electric Current is ___A

2.Total demand length ____M

3. Working Conditions_____

4. Your contact information. Both Email and phone number are essential.

FAQ

1. What information should I provide to get the price?

Specific parameters such as power supply voltage, electric current, total demand length, working conditions, etc.

2. Can you customize product ?

Yes, of course. we are manufacturer, and we have a lot of experienced engineers,They can design products according to customer.

3. How can you ensure your quality?

Before the delivery, every products will be tested. You are also warmly welcomed to come to our factory for inspection.

4. How to ship to the destination?

Usually,we transport goods by sea at low cost.If it is urgent,cargo can be transported by air.

The manufacturing technology level is leading in China.the production scale and capacity are in the forefront of the same industry. Our mission is to supply the full solution for all types of lifting systems.

Похожие товары

Производитель ICTI надувные поплавки из пенопласта для

Оптовая продажа, индивидуальная этикетка, дизайнерские прочные сумки, модные шелковистые атласные полиэфирные прочные сумки унисекс для мужчин

Горячая распродажа! enoby тела кларнет в Bb

Xangshi XS97 оптовая продажа xs97mini AMLOGIC s905w2 Смарт ТВ-бокс a95x max на базе

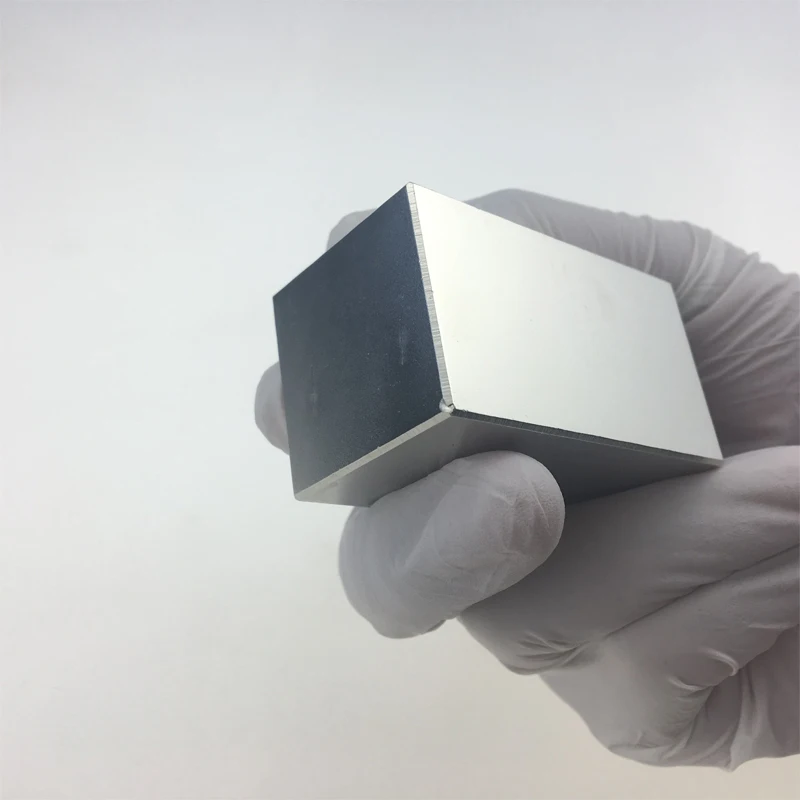

N42 супер сильный Неодимовый бар магнит для научных

Горячая распродажа! Один двойной 3-х местная большие и маленькие прочный кресло-качалка Висячие качели для патио мебель из ротанга индия

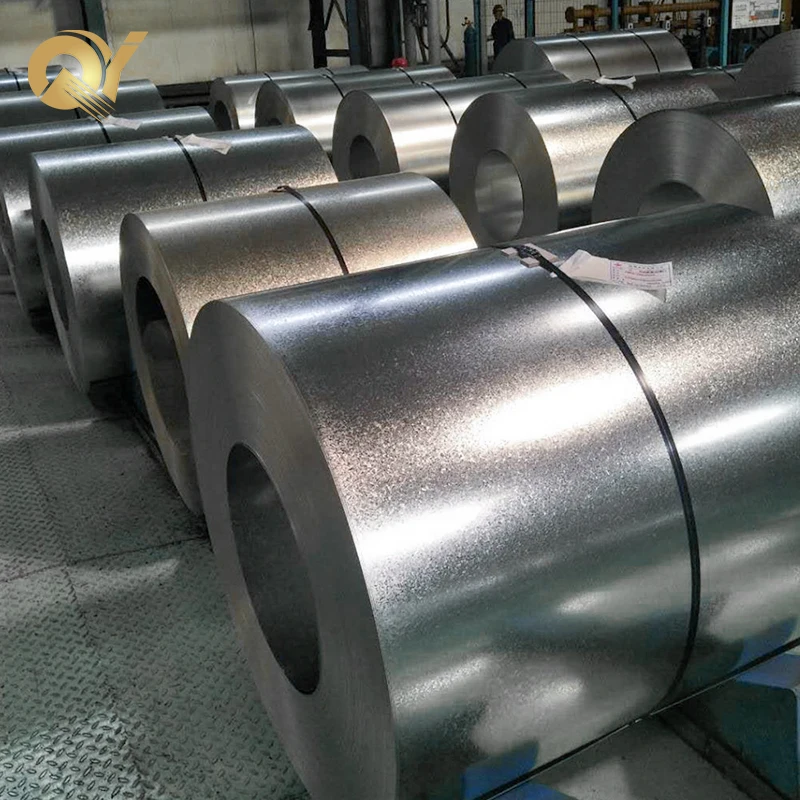

Высококачественная и недорогая оцинкованная стальная катушка холоднокатаная сталь марки DX51D

Новые поступления

Новинки товаров от производителей по оптовым ценам