Шлифовальная машина для деревянных дверей щетка из твердой древесины МДФ шлифовальная шкафа

- Категория: >>>

- Поставщик: Qingdao Giantway Machinery Co. Ltd.

Сохранить в закладки 1600371123312:

Описание и отзывы

Характеристики

Products Description

Vacuum Feeding Table

Vacuum Feeding Table helps to hold the working pieces and ensure the smooth feeding.

Z

Cross brush rollers to polish the boards from right side to left side, especially for polishing board cross grooves.

X

Sanding disc units, rotating and oscillating, is good on surface polishing or corners polishing.

W

Longitudinal brush rollers is good on polishing longitudinal grooves and sags or crests working parts.

Machine Specifications

MODEL | YHS1100Z+X+W+W |

Working width | 1100mm |

Working thickness | Max 100mm |

Cross brush rollers speed | Max 550rpm (inverter) |

Sanding discs speed | Max 500rpm (inverter) |

Horizontal brush rollers speed | Max 550rpm (inverter) |

Cross brush rollers oscillating frequency | Max 30times/min (inverter) |

Discs station oscillating frequency | Max 30times/ min (inverter) |

Horizontal brush rollers oscillating frequency | 60times /min |

Feeding speed | 0-19m/min |

Cross brush rollers diameter | 320mm (8pcs) |

Sanding discs diameter | 180mm (11pcs) |

Horizontal brush rollers diameter | 320mm (4pcs) |

Total motor power | 24.61kw |

Feeding motor | 4kw |

Cross brush rollers motor | 1.5kw |

Cross brush rollers oscillating motor | 0.75kw |

Horizontal brush rollers motor | 1.5kw * 4 pcs |

Horizontal brush roller oscillating motor | 0.37kw * 2pcs |

Discs motor | 1.5kw |

Discs qty | 22 pcs |

Discs station oscillating motor | 0.75kw |

Working units rise and decline motor | 1.5kw |

Press rollers rise and decline motor | 0.37kw |

Vacuum pump motor | 7.5kw |

Dust outlets | 4* Ø150mm |

Vacuum table exhaust outlet | Ø200mm |

Overall dimension | 4000*1900*2200mm |

Weight | 4900kgs |

Product introduction

Brush sanding machine is the latest innovation in sanding technology, featuring cross brush rollers, sanding discs and longitudinal brush rollers. This configuration makes this sander a ideal finishing solution for doors, cabinets, shutters, face frames and other furnitures. Giantway brush sanding machine can do both white wood sanding or lacquer sanding by using different abrasive strips.

Giantway brush sanding machine is to help remove wood fibers from sanding the product, to help break sharp edges on product to prevent white lining, to help blend in or make uniform staining, to help blend in cross grain scratch, sanding imperfection & handling marks.

This machine YHS1100 Z+X+W+W, Z is for cross brush rollers, X is for sanding discs, W is for longitudinal brush rollers. According to customers' requirement, we can make Z+X+W+W, Z+X+W, Z+W+W or W+ W+W and other different combination.

Giantway brush sanding machine is to help remove wood fibers from sanding the product, to help break sharp edges on product to prevent white lining, to help blend in or make uniform staining, to help blend in cross grain scratch, sanding imperfection & handling marks.

This machine YHS1100 Z+X+W+W, Z is for cross brush rollers, X is for sanding discs, W is for longitudinal brush rollers. According to customers' requirement, we can make Z+X+W+W, Z+X+W, Z+W+W or W+ W+W and other different combination.

Product Line

Our Company

Quality Testing

Certification

Our Partner&Exhibition

Packaging&Shipping

FAQ

1.What is a good wide belt sander?

A good wide belt sander should have below characteristics.

1, High precision, a good sander has to do a good calibrating job, after sanding, the thickness tolerance maximum is 0.1mm.

2, Making good surface, a perfect belt sander has to produce a good surface, no sanding marks left on the whole surface.

3, Easy to run and maintenance, a wonderful machine should be easy to operate and no difficulty for maintenance.

4, Working stability and low repair rate, a good wide belt sander has to be a stabilized equipment, with very low repair rate, and guarantee the customers’ production no stop.

5, Long life, an excellent machine need have a long life, Giantway has some machines have been working for more than 20 years

A good wide belt sander should have below characteristics.

1, High precision, a good sander has to do a good calibrating job, after sanding, the thickness tolerance maximum is 0.1mm.

2, Making good surface, a perfect belt sander has to produce a good surface, no sanding marks left on the whole surface.

3, Easy to run and maintenance, a wonderful machine should be easy to operate and no difficulty for maintenance.

4, Working stability and low repair rate, a good wide belt sander has to be a stabilized equipment, with very low repair rate, and guarantee the customers’ production no stop.

5, Long life, an excellent machine need have a long life, Giantway has some machines have been working for more than 20 years

2.What kind of sanding machine I need to buy?

1, This depends on your product and production capacity. A small work shop maybe need one sanding machine only.

2, For big factories and big production capacity, you need to buy many machines for calibrating job and fine sanding job, you also need to buy lacquer sanders for the sealer sanding job.

3, For big stock removal job, such as jointed panels, bamboo panels, you need to buy the planer sander.

4, For carving boards or pattern boards, you need to buy Giantway brush sanders.

1, This depends on your product and production capacity. A small work shop maybe need one sanding machine only.

2, For big factories and big production capacity, you need to buy many machines for calibrating job and fine sanding job, you also need to buy lacquer sanders for the sealer sanding job.

3, For big stock removal job, such as jointed panels, bamboo panels, you need to buy the planer sander.

4, For carving boards or pattern boards, you need to buy Giantway brush sanders.

3.Are you a trade company or manufacturer?

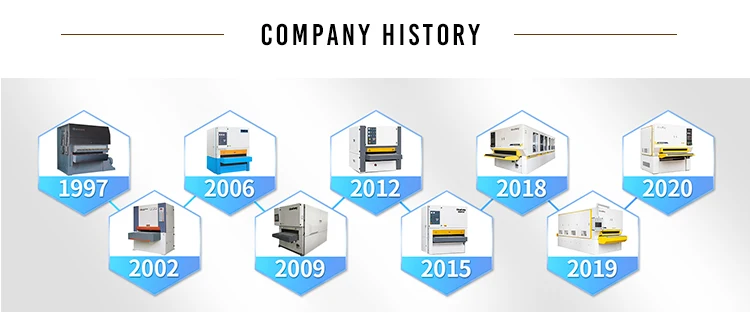

We are a professional sanding machine manufacturer since 1997, before 2005, we are called Qingdao JCH Woodworking Machinery Co., Ltd.. We have 15000 square meters workshop in Qingdao, China, and 200 staffs. We can make more than 1000 sets sanding machine per year, and export 40% to worldwide.

We are a professional sanding machine manufacturer since 1997, before 2005, we are called Qingdao JCH Woodworking Machinery Co., Ltd.. We have 15000 square meters workshop in Qingdao, China, and 200 staffs. We can make more than 1000 sets sanding machine per year, and export 40% to worldwide.

4.How long is the delivery time?

We usually deliver our goods within 21 days after getting your advance payment. But if the electric power in your country is different with China (380V/ 50hz / 3p), for example, your power is 460V / 60HZ/ 3P, we need 40 days to delivery your goods.

We usually deliver our goods within 21 days after getting your advance payment. But if the electric power in your country is different with China (380V/ 50hz / 3p), for example, your power is 460V / 60HZ/ 3P, we need 40 days to delivery your goods.

5.Can you help the customer to install the machines?

Yes, we can. We have 3 options for you:

1, There is a manual book with every machine, you can install the machine with the instruction on the manual. Most customers can do the installation according to the manual.

2, We can provide video service to help you solve all the problems you maybe meet, including the installation, and it is free of charge.

3, We can go to your place to help you install the machines. But you need to pay for the journey cost and USD100 service fees per day.

Yes, we can. We have 3 options for you:

1, There is a manual book with every machine, you can install the machine with the instruction on the manual. Most customers can do the installation according to the manual.

2, We can provide video service to help you solve all the problems you maybe meet, including the installation, and it is free of charge.

3, We can go to your place to help you install the machines. But you need to pay for the journey cost and USD100 service fees per day.

6.How is the after sales service?

Our machine guarantee time is 18 months from the BL date, but service is for ever. We can supply call service, internet service, video service at any time. We also can arrange engineers to visit your place and help you to maintain or repair the machine.

Our machine guarantee time is 18 months from the BL date, but service is for ever. We can supply call service, internet service, video service at any time. We also can arrange engineers to visit your place and help you to maintain or repair the machine.

Похожие товары

DN20 PN30 никелированный латунный шаровой кран с резьбой BSP

2,25 $ - 4,25 $

1 кВт 2 кВт 3 кВт домашний портативный бензиновый генератор

Многофункциональные Женские бамбуковые вязаные пляжные складные шляпы от солнца с цветочным узором

2,84 $ - 3,09 $

Машина для переработки пенополистироловых отходов, машина для переработки пенополистирола, машина для переработки горячего расплава пенополистирола

2 000,00 $ - 2 200,00 $

9H закаленное стекло 2.5D Arc Edge Чувствительная Сенсорная Пленка высокой четкости для Oppo Realme 5 Pro защита экрана

Оцинкованная, покрытая, цветная сталь/лист из нержавеющей стали

1,98 $ - 2,55 $

Жгут проводов двигателя 320/A9998 322838401, J C B JS210 JS220 JS230 JCB444 JCB448, жгут проводов 320 09727 322838401 320/A9998

50,00 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $