Независимые исследования и разработка горячей 2 25 мл NLGF Тип Schering бутылки жидкость заполнение мойка сушка Стопорная соединительная линия

- Категория: >>>

- Поставщик: Shanghai Nalong Intelligent Technology Co. Ltd.

Сохранить в закладки 1600372831647:

Описание и отзывы

Характеристики

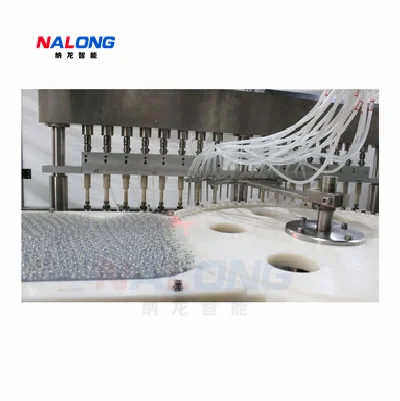

NLGF2-25 schering bottles liquid washing drying filling barging linkage line

Purpose and introduction :

NLGF2-25 schering bottles liquid washing drying filling barging linkage line consists of QCL series vertical ultrasonic bottle

washer, ASMR tunnel hot air circulation oven, NLGF electro schering bottles liquid filling barging into a crew, and also can be used stand-alone. Used in the 2-25 ml specification schering bottles of water production. Can finish the spray water injection, ultrasonic thick bottle washing, the outer wall of water flushing, bottle wall continuous secondary circulating water flushing, a blowing, a fresh water rinse, two consecutive bottle blowing, blowing the outer wall, preheating and drying sterilization before going to pyrogen, cooling, inflatable, filling, after filling, stoppering, etc more than 20 procedures.

characteristic:

◆Bottle washer adopts manipulator clamp bottle, is suitable for a variety of specifications of schering bottles;

◆Reciprocating mixer washing bottle with water spray needle track insert way, cleaning effect is good, save energy. Shake with needle frame;

◆Mixer washing bottle the water pipe, injection needles completely separate, to avoid the cross contamination, in line with the GMP requirements;

◆Pieces out of the bottle inside the screw before adding buffer block, protect the screw, reduce broken bottle;

◆Pieces out of the bottle inside the whole import synchronous belt, the connection piece of conveying ampoule bottle, operation is stable and reliable;

◆Oven adopts hot air circulation heating, temperature uniformity, energy saving;

◆Mixer oven has suddenly loses power protection function, safe operation;

◆Mixer oven can match circulating water cooling device, not loss room air volume, reduce the risk of differential pressure

imbalance in room, cooling effect is good;

◆Mixer oven can match the differential automatic balance adjustment system, reduce the room and high temperature oven pressure difference caused by the imbalance of period of migration, filling between wash between baking temperature and so on a series of problems;

◆Mixer oven with DOP test interface (including wind pressure, wind speed, dust particle detection);

◆Mixer oven cooling segment with the function of sterilization ;

◆Type mixer oven mesh belt with ultrasound scanning CIP online cleaning system;

◆In pieces inside the oven cavity can be all-round, multi-angle high-pressure water flushing;

◆In pieces filling machine adopts horizontal synchronous belt bottle mode, high speed, and bottles of accurate, replacement of a convenient;

◆In pieces at the bottom of the bottle in the transport plane and work table there is a certain distance, is advantageous to the best level layer by wind, turbulence prevents pollution solution;

◆Pieces filling machine gasser part, uses the level to plug, and horizontal disc vacuum plug, are convenient to observe, loading convenient, to plug the characteristics of high speed;

◆In pieces filling machine can match ceramic pump, stainless steel pump, peristaltic pump;

◆In pieces filling machine no bottle filling, no bottle no gasser function;

◆In pieces filling machine optional servo filling forms, mitsubishi, schneider (Taiwan).

◆The whole line adopts PLC control, inverter, touch screen control technology, the operation is stable and reliable; The operation of the touch screen can display the single machine dynamics, the control points of hydraulic pressure, air pressure, air pressure, temperature, etc, according to the switch state and fault display, fault self-diagnosis and fault analysis and elimination method, make the whole production process automation control, on-line has the compressors control balancing device, ensure production is balanced.

According to the needs of customers, but also available for selection:

◆Pieces of Siemens, schneider, mitsubishi, Taiwan brands such as control system;

◆Pieces of water, gas pressure, water temperature and the intensity of ultrasonic, dust particles, wind speed on-line detection, alarm, record and print system;

washer, ASMR tunnel hot air circulation oven, NLGF electro schering bottles liquid filling barging into a crew, and also can be used stand-alone. Used in the 2-25 ml specification schering bottles of water production. Can finish the spray water injection, ultrasonic thick bottle washing, the outer wall of water flushing, bottle wall continuous secondary circulating water flushing, a blowing, a fresh water rinse, two consecutive bottle blowing, blowing the outer wall, preheating and drying sterilization before going to pyrogen, cooling, inflatable, filling, after filling, stoppering, etc more than 20 procedures.

characteristic:

◆Bottle washer adopts manipulator clamp bottle, is suitable for a variety of specifications of schering bottles;

◆Reciprocating mixer washing bottle with water spray needle track insert way, cleaning effect is good, save energy. Shake with needle frame;

◆Mixer washing bottle the water pipe, injection needles completely separate, to avoid the cross contamination, in line with the GMP requirements;

◆Pieces out of the bottle inside the screw before adding buffer block, protect the screw, reduce broken bottle;

◆Pieces out of the bottle inside the whole import synchronous belt, the connection piece of conveying ampoule bottle, operation is stable and reliable;

◆Oven adopts hot air circulation heating, temperature uniformity, energy saving;

◆Mixer oven has suddenly loses power protection function, safe operation;

◆Mixer oven can match circulating water cooling device, not loss room air volume, reduce the risk of differential pressure

imbalance in room, cooling effect is good;

◆Mixer oven can match the differential automatic balance adjustment system, reduce the room and high temperature oven pressure difference caused by the imbalance of period of migration, filling between wash between baking temperature and so on a series of problems;

◆Mixer oven with DOP test interface (including wind pressure, wind speed, dust particle detection);

◆Mixer oven cooling segment with the function of sterilization ;

◆Type mixer oven mesh belt with ultrasound scanning CIP online cleaning system;

◆In pieces inside the oven cavity can be all-round, multi-angle high-pressure water flushing;

◆In pieces filling machine adopts horizontal synchronous belt bottle mode, high speed, and bottles of accurate, replacement of a convenient;

◆In pieces at the bottom of the bottle in the transport plane and work table there is a certain distance, is advantageous to the best level layer by wind, turbulence prevents pollution solution;

◆Pieces filling machine gasser part, uses the level to plug, and horizontal disc vacuum plug, are convenient to observe, loading convenient, to plug the characteristics of high speed;

◆In pieces filling machine can match ceramic pump, stainless steel pump, peristaltic pump;

◆In pieces filling machine no bottle filling, no bottle no gasser function;

◆In pieces filling machine optional servo filling forms, mitsubishi, schneider (Taiwan).

◆The whole line adopts PLC control, inverter, touch screen control technology, the operation is stable and reliable; The operation of the touch screen can display the single machine dynamics, the control points of hydraulic pressure, air pressure, air pressure, temperature, etc, according to the switch state and fault display, fault self-diagnosis and fault analysis and elimination method, make the whole production process automation control, on-line has the compressors control balancing device, ensure production is balanced.

According to the needs of customers, but also available for selection:

◆Pieces of Siemens, schneider, mitsubishi, Taiwan brands such as control system;

◆Pieces of water, gas pressure, water temperature and the intensity of ultrasonic, dust particles, wind speed on-line detection, alarm, record and print system;

product model | QCL60+ASMR620/35 +KGF4 | QCL60+ASMR620/43 +KGF6 | QCL60+ASMR620/43 +KGF8 | QCL80+ASMR620/48 +KGF10 | QCL120+ASMR800/55 +KGF12 | QCL120+ASMR1250/60 +KGF20 | QCL80*2+ASMR1250/60 +KGF12*2 | ||||||

Cutting dimension (ml) | 2-25 (International vial) | 2-25 (International vial) | 2-25 (International vial) | 2-25 (International vial) | 2-25 (International vial) | 2-25 (International vial) | 2-25 (International vial) | ||||||

Filling heads | 4 | 6 | 8 | 10 | 12 | 20 | 24 | ||||||

production capacity (pcs/h) | 120(7ml) | 180(7ml) | 200(7ml) | 300(7ml) | 400(7ml) | 500(7ml) | 650(7ml) | ||||||

Washing bottle percent of pass(%) | ≥ 99 | ≥ 99 | ≥ 99 | ≥ 99 | ≥ 99 | ≥ 99 | ≥ 99 | ||||||

Washing bottle breakage(%) | ≤ 0.1 | ≤ 0.1 | ≤ 0.1 | ≤ 0.1 | ≤ 0.1 | ≤ 0.1 | ≤ 0.1 | ||||||

sterilizing temperature (°C) | 300-350 | 300-350 | 300-350 | 300-350 | 300-350 | 300-350 | 300-350 | ||||||

exhaust air rate (m3/h) | 3000 | 3000 | 4100 | 4100 | 7500 | 8,000-10,000 | 8,000-10,000 | ||||||

Filling accuracy (%) | ≤ ±2.5 (机械式驱动容积泵、陶瓷泵、不锈钢泵) ≤ ± 0.5-1.0 (伺服驱动容积泵) | ||||||||||||

Gasser percent of pass(%) | ≥ 99 | ≥ 99 | ≥ 99 | ≥ 99 | ≥ 99 | ≥ 99 | ≥ 99 | ||||||

Laminar air cleanliness (Class) | 100 | 100 | 100 | 100 | 100 | 100 | 100 | ||||||

Vacuum pumping speed(m3/h) | 10 | 30 | 50 | 60 | 60 | 100 | 120 | ||||||

capacitance | 66.6 | 75.6 | 75.6 | 106.6 | 106.6 | 212.6 | 232.6 | ||||||

power supply | 385V 50Hz | 385V 50Hz | 385V 50Hz | 385V 50Hz | 385V 50Hz | 385V 50Hz | 385V 50Hz | ||||||

total weight (kg) | 6300 | 6300 | 7900 | 7900 | 9400 | 10900 | 14600 | ||||||

Похожие товары

Химическое смешивание, лабораторная мешалка, стеклянный реактор, используемый в фармацевтических исследованиях

Новые исследования и разработки Открытый водонепроницаемый 20 оптический зум Hd мини инфракрасная Ir Ptz камера для скорой помощи

480,00 $ - 500,00 $

Лабораторный гомогенизатор высокого давления для исследований

16 200,00 $ - 18 000,00 $

Взрывозащищенный роторный испаритель нового типа, химическое устройство для научных исследований, образовательных и пилотных тестов биологических, фармацевтических исследований

5 799,00 $ - 5 899,00 $

0,2 мл ПЦР блокировочная центрифуга с несколькими отверстиями трубчатая стойка с 120 отверстиями

210,00 $ - 220,00 $

Новейшие исследования и производство высококачественной автоматической машины для предварительного растяжения пленки

GMS-20-4 образец порошка подготовки лаборатории стана крена для университета научный эксперимент

2 200,00 $ - 2 400,00 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $