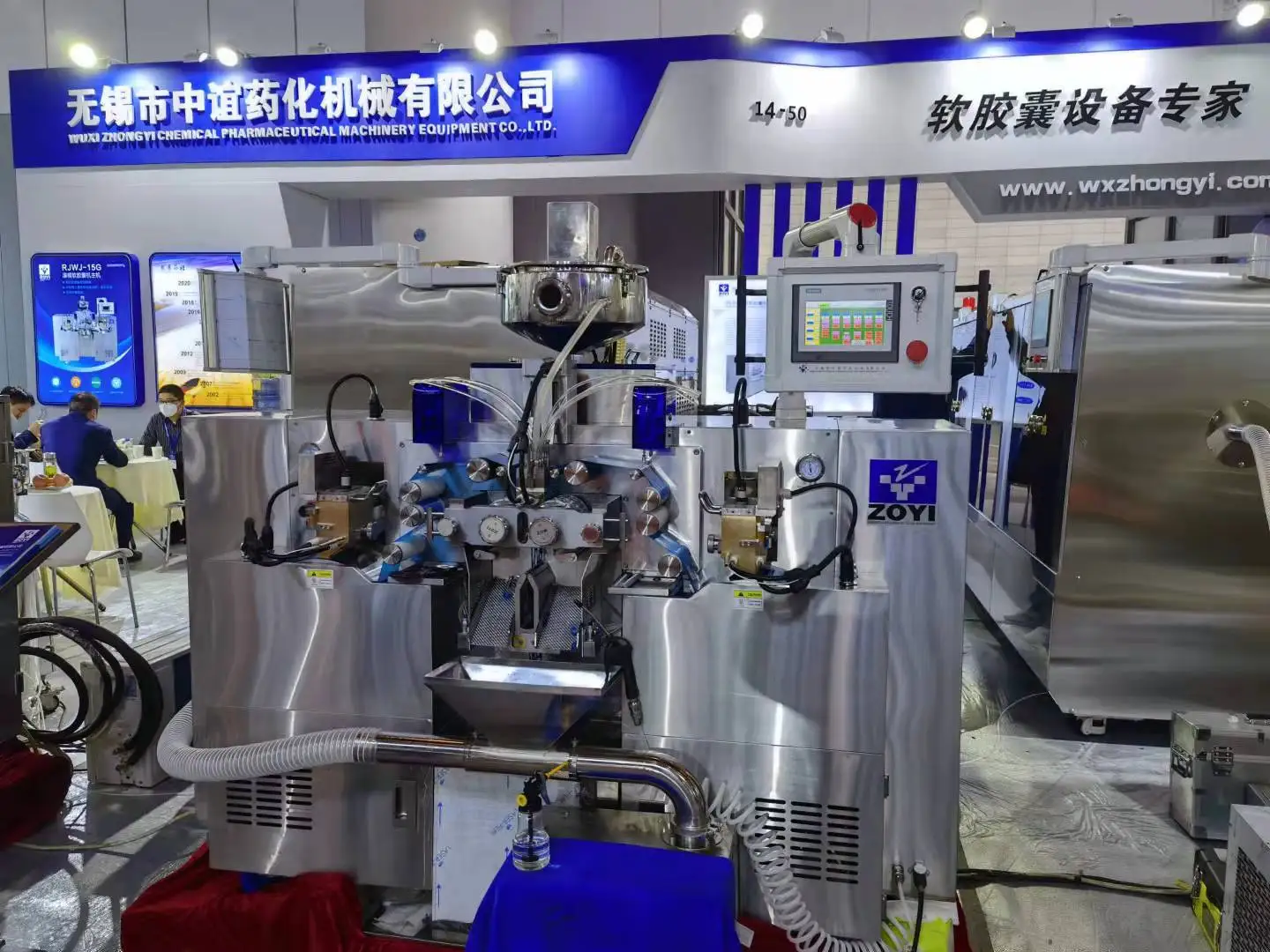

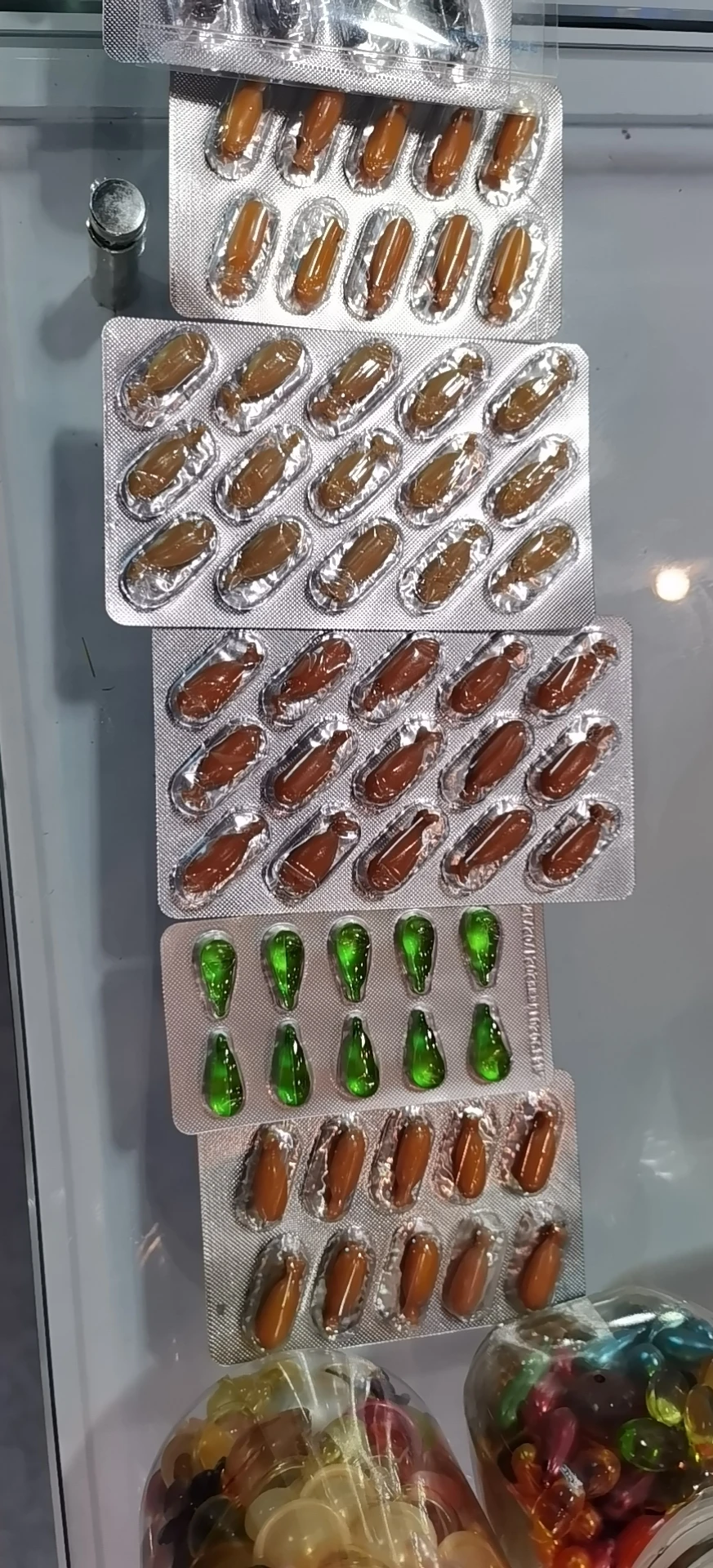

Автоматическая машина для производства бесшовного масла желатина мягкого геля Капсульная линия

- Категория: >>>

- Поставщик: Wuxi Zhongyi Chemical Pharmaceutical Machinery Equipment Co. Ltd.

Сохранить в закладки 1600375274474:

Описание и отзывы

Характеристики

Automatic seamless oil gelatin soft gel making machine capsule line

RJWJ-15G soft capsulation production line is of large scale production equipment. The single unit annual production capacity is 4 hundred million capsules. Adopts international advanced control technology, precisely design precisely producing, it is the dependable equipment for the production of high quality soft capsules.

Humanized design, easy to operate.The mold matches the mold shaft, to avoid damage in the process of loading and unloading.

Special injection assembly protects injection body from damage during loading and unloading, and reduces labor intensity of operators.

All daily maintenance parts are simplified design, convenient and efficient.

Professional industrial aesthetic design makes the overall appearance of artistic.

Paramater

| Die roller speed | 0-6 RPM (frequency control) |

| Die roller size | φ150x250mm |

| Single-piston feed rate | 0-2ml, 0-3ml Customizable |

| Capacity | 60,000 caps/h, 8# olive(500mg), 30 Kg/H |

| Load difference | ≤±2% |

| Load precision | ±1% |

| Motor power | 1.5kw |

| Total power | 12kw |

| Power supply | 380V, 50Hz |

| Weight | 1400kg |

| Dimension | 2260x1000x2060mm |

Advantages

Each drive system independent control, coordinate and convenient to adjust.

Roll mold pressurization is pneumatic pressurization, digital display, easy and convenient.

Low noise design, the noise does not increase at the highest speed and the lowest speed operation, improve the working environment.

Adopts non-oil or micro-oil lubrication, mostly no oil press capsule, reduce production costs, clean working environment

Soft capsule no need alcohol cleaning, avoid the damage of the solvent on the capsule (except printed capsules)

The thickness of gelatin piece can be adjusted by PLC, precision adjustment, digital display, reduce the gelatin making time, save the cost. The gelatin level is automatically controlled by the level sensor.

Gelatin pieces of the two sides convey in line, no need adjustment, stable production.

Roll mold adjustment: free on line design, simplified operation, avoid man-made error.

Injection body lifting type: electrical driven,self lock, safe and dependable. The spray body adopts water heating method, the temperature is uniform, the soft capsule closure is improved, and the phenomenon of large and small head at both ends is reduced.

Feed pump: adjustable design, easy installation, all rolling bearing design, prolong the service life

Capsule cooling method: automatic water cooling and air balance come with the machine. Temperature control range: 6 ~ 25℃, temperature difference between plus or minus 0.1 ℃.

Quick shaping of capsules: the unique air supply device reduces the local temperature of the capsule area and tends to shape the capsules.

Temperature control hopper: precise temperature control, automatic level control, suitable for all kinds of material requirements.

Independent non-clearance gear design, so that the upper and lower joints are basically the same, increase the finished product ratio.

Use ceramic pump rod, never wear

The rubber wheel with special processing, hardness of HB45 , enhance the rubber surface finish, prolong service life.

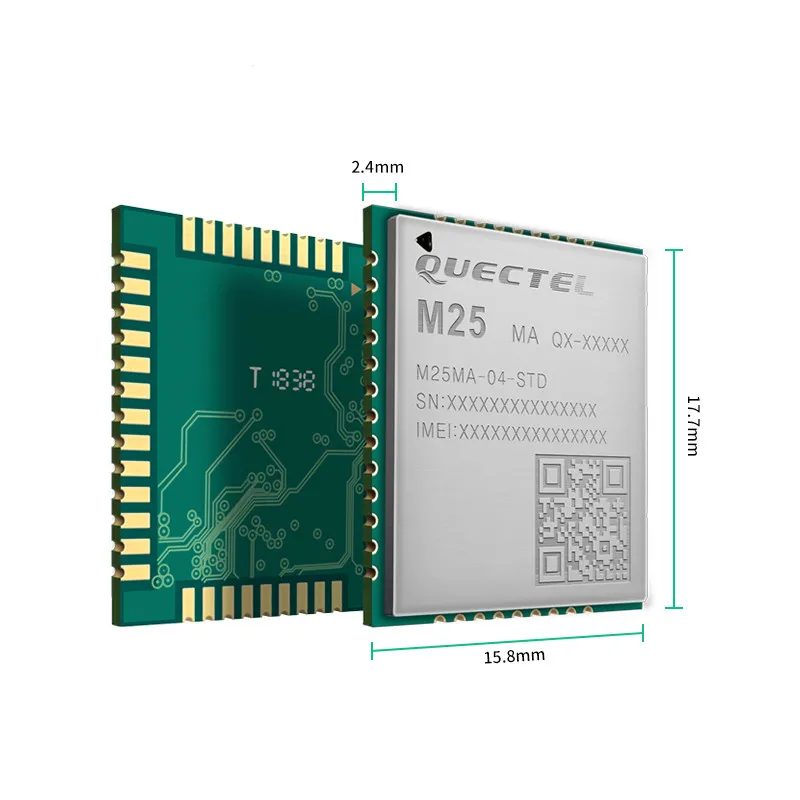

Electric control system using Schneider, Delta (customized) PLC control.

Electronic controls are imported devices, so that the electronic control system control stability excellent performance, so as to ensure the quality of soft capsule machine.

Adopt constant temperature water heating hopper.

Q: Where is your factory? How to visit your factory?

A: Our factory is located in Wuxi City, Jiangsu Province. We sincerely welcome you to visit our factory!

Q: How can I trust you for the first-time business?

A: Please note our business license and certificates above. If you don't trust us, we suggest using Alibaba Trade Assurance Service for all transactions to protect your money and assure our service for you.

Q: Could you supply process recipe if buy your machine?

A: Yes, of cause.

Q: What's you characteristic service?

A: We can help you setting up a completed production line from cleanroom, layout, machines, workers training…

Q: How is the guarantee period?

A: We offer 12 months warranty since the arrival of the machine.

Sarah Li

WhatsApp: +86-18261536626

WeChat: 18261536626

Skype: sarahddzg

Похожие товары

ZT-100L нержавеющая сталь косметический крем, лосьон для тела, косметическая мазь вакуумный гомогенизирующий эмульгатор/порошок тестомесильная машина/mixer/смешивания

Маленькие цветы, горячее сверление, корейские красивые леггинсы, комбинезоны, держатель для чулок, черные ножки, зрелые чулки

Светодиодный УФ dtf принтер CMYK imпраora a3 для любых изделий из неправильных материалов с УФ-принтером dtf для UV dtf пленочная печать

Принтер Micolorprint Dtg, струйный текстильный принтер для печати на футболках, шелковом, шерстяном, хлопковом принтере, принтер A3 + Dtg

Красивый полный ковер в рулоне, полипропиленовый ковер с поверхностью, Фабричный ковер от стены к стене, ткацкий ковер

Горячая Распродажа 2021, 60 см, Двойные головки i3200, цифровой рулон, Dtf ПЭТ пленка, теплопередающая машина для печати футболок

2021 Продажа с завода, новый DTF принтер с порошковой пленкой, принтер A3 A2 DTF

Новые поступления

Новинки товаров от производителей по оптовым ценам