Высококачественная автоматическая машина для облицовки краев ПВХ

- Категория: >>>

- Поставщик: Jinan Bcamcnc Machinery Co. Ltd.

Сохранить в закладки 1600380017675:

Описание и отзывы

Характеристики

Product Description

BCAMCNC , a professional machinery manufacturing company, with 6000 square meters factory,a highly specialized workforce and more than 10 Patent Technologies has gained a global reputation as one of the most reliable and trusted CNC machinery solution providers.

BCAMCNC comprehensive in the production, design, manufacturing, trade and service of CNC machine like CNC Router, Laser cutting machine, Digital cutting table, Fiber laser cutting machine and Edge banding machine etc., Our wide variety products used in the field of Woodworking, Sign Making, Panel Furniture Production, Jewelry pieces, Packaging etc.,

High quality products with the high production efficiency. All our products are precision engineered to ensure the high standard expected from ourselves. The whole manufacturing process is meticulously and systematically controlled to guarantee the precision and quality.

High quality products with the high production efficiency. All our products are precision engineered to ensure the high standard expected from ourselves. The whole manufacturing process is meticulously and systematically controlled to guarantee the precision and quality.

Control system

The machine is with functions as follows gluing ,end trimming ,rough trimming fine trimming,scraping,buffing .And since it is

physical scraping ,therefore there are five functions on the screen , so scraping function is not shown on the screen.

physical scraping ,therefore there are five functions on the screen , so scraping function is not shown on the screen.

Gluing

Make the edge-banding board and the edge-banding material evenly coated on both sides to ensure stronger adhesion

Buffing

Use a cotton polishing wheel to clean the processed plates, and polish the edge-sealing end surface smoother.

Scraping

It is used to eliminate the ripple marks caused by the cutting process of the non-linear motion of the trimming, so that the upper

and lower parts of the plate are smoother and cleaner

and lower parts of the plate are smoother and cleaner

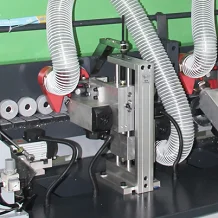

End trimming

Through the precise linear guide rail movement, the automatic tracking by the die and high-frequency high-speed motor cutting

structure are adopted to ensure smooth and smooth cutting surface

structure are adopted to ensure smooth and smooth cutting surface

Fine trimming

The structure of automatic profiling and high-frequency high-speed motor is adopted to ensure the smoothness of the upper and

lower parts of the trimmed plate. It is used to repair and process the excess edge banding material above and below the edge band

of the plate.

lower parts of the trimmed plate. It is used to repair and process the excess edge banding material above and below the edge band

of the plate.

Specification

Model | BCF450D | ||||

Motor power | 12.13kw | ||||

Overall size | 5800×1100×1600mm | ||||

Feed speed | 12-20m/min | ||||

Panel thickness | 10-60mm | ||||

Edge thickness | 0.4-3mm | ||||

Panel width | ≥80mm | ||||

Working pressure | 6kg | ||||

Weight | 2000kg | ||||

Pre-milling | ● | optional | |||

Gluing | ● | ||||

End trimming | ● | ||||

Rough trimming | ● | ||||

Fine trimming | ● | ||||

Profiling unit | ● | ||||

Scraping | ● | ||||

Buffing | ● | ||||

Grooving | ● | ||||

Company Profile

The full-automatic edge banding machine can polish the edge banding board, so that the color and smoothness of the edge banding board can be better The full-automatic edge banding machine can also scrape the ripple marks generated in the process of curve edge banding to ensure the smoothness of plate edge banding and our rounding parts the full-automatic edge banding machine can apply glue on both sides of the processed work piece and edge banding strip through special effing and structure, so as to make the adhesion between edge banding strip and plate more firm

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

FAQ

1. This is the first time I use this kind of machine, is it easy to operate?

1) English guide video and instruction book are sent to you free together with the edge banding machine.

2) Free training course in our factory. Engineers are available to serve overseas.

3) 24 hours technical support by calling, video and email.

Please call us for price quote : Cell phone/WhatsApp/Wechat :0086 15165128676

2. Do you have a setup and equipment commissioning service?

Yes, we have.

The machine was installed and debugged before delivery.You can use the machine directly after receiving it.Of course, we also could let our technologists go to your country to install and debug the machine.

3.How to choose a suitable machine?

You can tell us the working piece material, size, and the request of machine function. We can recommend the most suitable machine according to our experience. Or we can customize one for you. Kindly find us on whatsapp:+86 15165128676

4.What is the warranty period for the equipment?

Three years warranty and machine whole life 24 hours online professional technical support.

5.Payment terms,There are 3 ways to pay money.

1) T/T, means international bank transfer. 50% deposit, we produce the machine for you after received your deposit . 50% before shipping the machine. It is convenient and fast for your money.

2) Alibaba Secure payment. Reliable and safe, Alibaba will charge a little handling fee.

3)Cash

1) English guide video and instruction book are sent to you free together with the edge banding machine.

2) Free training course in our factory. Engineers are available to serve overseas.

3) 24 hours technical support by calling, video and email.

Please call us for price quote : Cell phone/WhatsApp/Wechat :0086 15165128676

2. Do you have a setup and equipment commissioning service?

Yes, we have.

The machine was installed and debugged before delivery.You can use the machine directly after receiving it.Of course, we also could let our technologists go to your country to install and debug the machine.

3.How to choose a suitable machine?

You can tell us the working piece material, size, and the request of machine function. We can recommend the most suitable machine according to our experience. Or we can customize one for you. Kindly find us on whatsapp:+86 15165128676

4.What is the warranty period for the equipment?

Three years warranty and machine whole life 24 hours online professional technical support.

5.Payment terms,There are 3 ways to pay money.

1) T/T, means international bank transfer. 50% deposit, we produce the machine for you after received your deposit . 50% before shipping the machine. It is convenient and fast for your money.

2) Alibaba Secure payment. Reliable and safe, Alibaba will charge a little handling fee.

3)Cash

Похожие товары

Красная медная сетка 99.8% чистая медная ткань 200 300 400 сетка медная Проволочная Сетка Emf краска экранирование

6,50 $ - 9,00 $

Домашнее дистилляционное оборудование из нержавеющей стали, 10 л, 20 л, домашний дистиллятор

92,00 $ - 96,00 $

OEM, индивидуальная Шестерня для планетарного редуктора, редуктор скорости червячного редуктора swl

1 900,00 $

Полуавтоматическая машина для кромкооблицовки древесины ET-60

3 030,00 $ - 3 330,00 $

Лидер продаж, оборудование для дистилляции алкоголя, спиртовая Дистилляция для микропивоварни

Высокоскоростной кромкострогальный и прямой Кромкооблицовочный станок двойного назначения средний и большой деревообрабатывающий Кромкооблицовочный станок

3 900,00 $ - 4 250,00 $

Бытовая из нержавеющей стали дистилляции комплект машина для обработки воды эфирных масел/дистилляционная машина пивоваренной машины

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $