Угловая коробка машина для склеивания флексовых папок с автоматической функцией спрея и клея R5

- Категория: >>>

- Поставщик: Zhejiang New Luolan Machinery Co. Ltd.

Сохранить в закладки 1600383660340:

Описание и отзывы

Характеристики

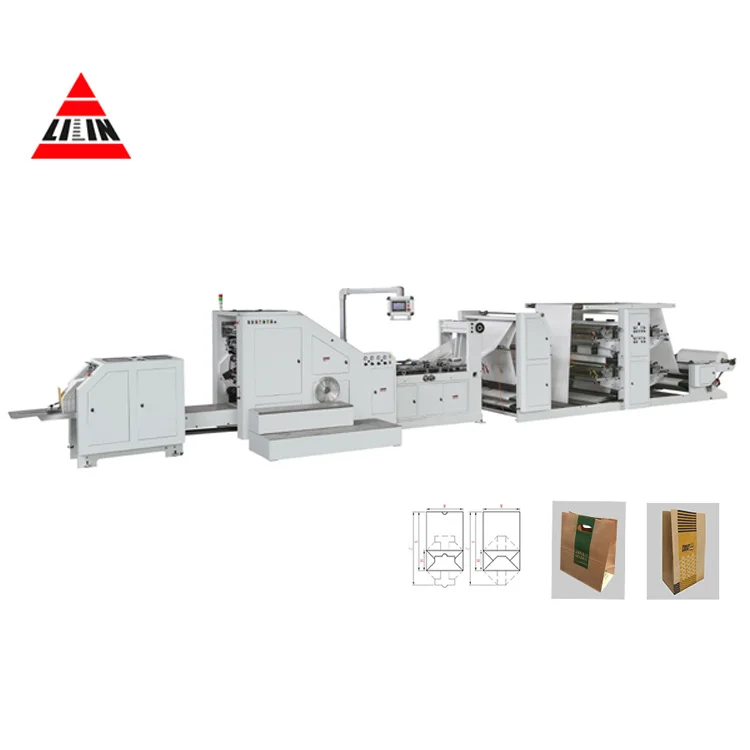

Auto Medicine Box Machine Folder Folding Gluer Gluing Wenzhou Ruian(GK-650GS/800GS/1100GS)

1. The main drive adopts ribbed v-belt featuring stable running and precised transmission.

2. Using servo motor drive for paper feeding to accurately adjust the feeding speed and adjust the density of the carton.

3. Using T-screw for the adjustment of all guide plates (electronic screw is optional),adjustment can be easily and accurately.

4. Several thicker belts with the vibrating motor (suction feeding is optional) make the paper feeding continuously and smoothly.

5.The highly integrated crutch shaping structure makes the adjustment of all standard and non-standard cartons easily.

6.The electric glue spraying system is convenient to remove and clean.

7. Crutch belt is with automatic tension function.

8. With small box positioning device, the taller or shorter boxes can be shaped accurately.

9. Adopt the photoelectric counter and kicking device.

10. The servo motor combined with the reverse hook device can finish the folding action accurately.

11. The transmission part can adjust the paper receiving position by sliding the belt up and down. It adapts to all carton models.

| Model | 650GS | 800GS | 1100GS |

| Paper Material | Cardboard 210-800g, A/B/E Corrugated | ||

| Speed Max | 400m/min | ||

| Inching Speed | 10m/min | ||

| Thickness of folded box max | 12mm | 20mm | 20mm |

| Blank Width | 650mm | 800mm | 1100mm |

| Length*Width*Height | 13*1.4*1.8m | 16.5*1.4*1.8m | 16.5*1.7*1.9m |

| Net Weight | 5T | 6T | 7.2T |

| Total Power | 22.5kw | 25.5kw | 29kw |

| Compressor Air | 6 bar | 6 bar | 6 bar |

| Air Compressor Capacity | 10m3/h | 10m3/h | 10m3/h |

| Air Tank Capacity | 60L | 60L | 60L |

| Feeding 1.Independently motorized servo motor control, simultaneous feeding mode with the main motor 2.Feeder section equipped with three pieces feeding knife, adjust the asymmetrical lengths as per the box sample.

|

3.Rail width can be horizontally adjusted and set by seven pieces 30mm thickened feeding belt and 10mm metal board. 4.Operators can operate feeder switch in any regional. 5.Embossing drive wheel guide the feeding section belt,side feed gates in the right and left are adjustable according to the products. 6.Vibration device coordinate with motor which helps machine consecutive and automatic feeding quick and simply. Feeder section can stack 400mm height paper board. | |

Aligner section 1.The paper board sent from feeder section will be corrected by aligner section to ensure transmission accurately. 2.Pressing drive pressure can be adjusted up and down to accommodate different paper board thickness.

|  |

| Pre-folding 1.Special first folding line pre-fold 180°. third line 165° ,which perfectly meeting the requirements of automatic packaging inCrdustry. |

Crash Lock bottom 1.Complete set of folding hooks and helixes to fold the front flaps of the blank smoothly and accurately. 2.Bottom lock section with three board, which can better apply to the large rash lock bottom box forming. 3.Sectional-type upper belt board with special design, which can be adjusted according to the products type ,no need to tension belt. |  |

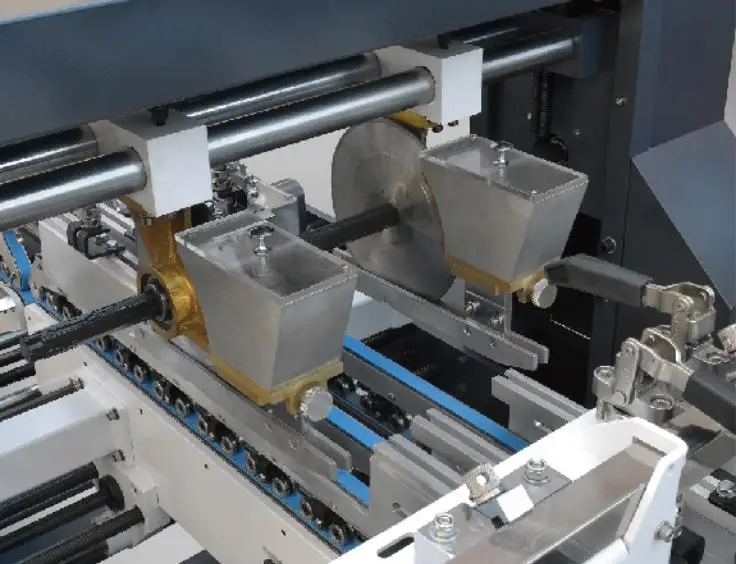

| Lower gluing tank 1.lower gluing tank is large volume. 2.Easy to remove and clean 3.Electronic upper gluing system by guns. |

Folding and Pressing 1.The Second and fourth folding line 180° 2.Folding and closing section transmit from right and left side ,the belt speed can be adjusted separately and correct the way of box running to ensure straightly delivery. |  |

| Trombone section 1.Up and down belt can be adjusted separately. 2.Equipped with photo electronic counting device and kicking paper device, which can press the paper after accounting and make it easy to pack . Also equipped with feeding paper inspection device. |

Transmission 1.Equipped with special additional sponge belt for the press of boxes valley part. 2.Upper section moves back and forward, allowing for different box length. 3.Pneumatic pressure regulator ,which can effectively ensure the uniform of fitting pressure, makes machine easy to adjust. |

|

Different Folder Gluer Available as below:

| folder gluer | folding gluing machine | window patching machine |

| folder gluer machine | folding and gluing machine | box making machine |

| automatic folder gluer | used folding gluing machine | paper box making machine |

| automatic folder gluer machine | paper bag folding gluing machine | making machine |

| folder gluer machine spare parts | automatic folding carton box gluing machine | cardboard box making machine |

| flexo folder gluer | carton folding and gluing machine | sweet box making machine |

| 4 6 corner automatic folder gluer machine | paper folding gluing machine | paper box machine |

| carton box folder gluer | automatic mini box folding gluing machine | corrugated box making machine |

| small box folder gluer | corrugated box folding gluing machine | corner pasting machine |

| carton folder gluer | box gluing machine | folding carton box gluing machine |

| lock bottom folder gluer | Gluing machine | folding machine |

1. What is the machine warranty?

one year.

2. Does your machine with CE certificate?

Yes, it does

3. What is the production time while placing order?

About 30 days

4. What is the delivery time?

Within 30 days after get the payment.

5. Can your company handle shipping for customers?

Yes.(Please provide us your requested seaport and we can check the shipping charge and arrange shipping for your order)

6. Does the packing strong?

Yes, of course! All of our export packing is with strong wooden pallets, all are confirmed to export packing standard.

7. How about after-sales service process?

When your machine has problem, contact your sales and we will solve your problem as soon as possible.

8. Are you manufacturer?

Yes, we are manufacturer with 10-year experience and profession.

9. Do you have stock product to sell?

Actually our machine need 20-30 days to manufacture, and there are many orders from China and foreign countries, so we need custom one for you, and your order will be highly attention to manufacture.

10. Do you inspect the finished products?

Yes, we have QC department, they will inspection the machine before shipping to ensure there is nothing problem of the machine .

11. What's the payment term?

T/T 30% in advance, the balance paid before delivery. We also accept payment via West Union and L/C.

We are professional manufacturer since 2005. We believe our products will provide

you with great business benefits and advantage.

Our faith:

1) Society's Avail First

2) Client's Avail First

3) Employee's Avail First

4) Enterprise's Avail Second

Похожие товары

Подходит для нескольких сценариев, переплетная машина для склеивания бумаг

Высокое качество, низкая цена, машина для нанесения этикеток на клеевой основе

5 ква 380 В 400 110/220 ВОЛЬТ новый открытый тип двигателя 186 трехфазный портативный промышленный с использованием электрического дизельного

Автоматическая машина для термоплавкого клея, пистолет для термоплавкого клея

Автоматическая машина для склеивания картонных коробок, машина для склеивания овощей, фруктов, коробок

Машина для скрученных бумажных ручек для бумажных пакетов

Прочный и устойчивый к высоким температурам термоплавкий клеевой Дозирующий связующий станок

Новые поступления

Новинки товаров от производителей по оптовым ценам