Высококачественная бумага для печати на струйной A4 футболках из 100% хлопка

- Категория: >>>

- Поставщик: Jiangyin Chenhao Technology Co. Ltd.

Сохранить в закладки 1600403280557:

Описание и отзывы

Характеристики

Five advantages

Transfer rate as high as 99%

The surface of nano coating is fine and the printing is clear

Washable and colorfast

The paper surface is smooth without paper jam and ink dragging

Widely used, customized

Transfer rate as high as 99%

The surface of nano coating is fine and the printing is clear

Washable and colorfast

The paper surface is smooth without paper jam and ink dragging

Widely used, customized

Material | Sublimation Transfer Paper |

Sample | 5-10m as your request, or A4 10-20 sheets for your selection,shipping cost self-paying |

Conventional Paper Width(mm) | 1118/1220/1320/1370/1520/1600/1620/1800/2400mm Jumbo Roll; A3/A4 Sublimation Transfer Paper(100sheets/pack); Customized Width & Length are available |

Application | Cotton Less Than 30%, Textiles, Fabric, Blend, Clothing,Jersey,Ceramic Mugs,Glass,Caps,Leather etc |

Delivery time | 7-15 days based on the quantity after receive the payment |

OEM & Design | Avaliable to cut into size you prefer and design your artwork |

The transfer pattern is delicate and lifelike

The transfer backing paper made according to the technical proportion has good thermal conductivity and heat resistance. The new transfer formula, transfer ink into the clothing fiber, fine pattern, let the transfer omnipotent

Environmental health, color lasting, not easy to crack, soft feel

The transfer backing paper made according to the technical proportion has good thermal conductivity and heat resistance. The new transfer formula, transfer ink into the clothing fiber, fine pattern, let the transfer omnipotent

Environmental health, color lasting, not easy to crack, soft feel

step1:

Print the picture you want to transfer(Only thermal sublimation ink is supported)

step2:

Print the picture on the thermal sublimation paper 【through the mirror printing mode】

step3:

Choose a T-shirt to burn(Non pure cotton light color clothes)Cotton content less than30%

step4:

Spread T-shirt on a hot stamping machine,Put the printed transfer paper on the part of T-shirt to be hot stamping(Face down with pattern),Transfer printing

step5:

Personalized T-shirt, successful transfer printing

pay attention to

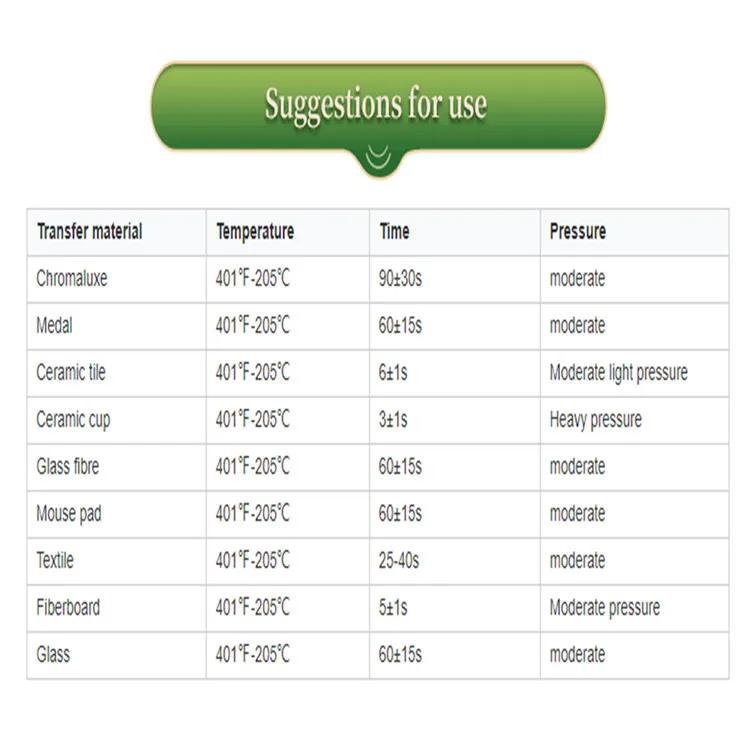

After heating to 330 degrees Fahrenheit, press down the cover plate for hot stamping. The hot stamping time is about 20 seconds;

330 ° f = 165.5 ° C

Print the picture you want to transfer(Only thermal sublimation ink is supported)

step2:

Print the picture on the thermal sublimation paper 【through the mirror printing mode】

step3:

Choose a T-shirt to burn(Non pure cotton light color clothes)Cotton content less than30%

step4:

Spread T-shirt on a hot stamping machine,Put the printed transfer paper on the part of T-shirt to be hot stamping(Face down with pattern),Transfer printing

step5:

Personalized T-shirt, successful transfer printing

pay attention to

After heating to 330 degrees Fahrenheit, press down the cover plate for hot stamping. The hot stamping time is about 20 seconds;

330 ° f = 165.5 ° C

How to distinguish the front and back of paper

Method 1:

Our thermal sublimation paper is treated by a special process. Not only the front side has a transfer coating, but also the back side has been coated. It has strong water absorption and can effectively prevent the printing face from warping and scratching the nozzle. But if the reverse side is up, it will curl, as shown in the figure below

(1. This is the hot sublimation paper just taken out. The paper is flat and does not bend.)

(2. After five minutes, the paper with the reverse side up has been bent, and the paper

with the front side up is flat without bending.)

with the front side up is flat without bending.)

Method 2:

If you stick the water with your fingers, you can stick to the front of your forehead, and vice versa. This is because there is a coating on the front, which will be sticky when encountering water

Remind buyers here:

1) The normal printing of thermal sublimation transfer paper, are printed face up, back down, if the cross warping, most of the factors are reversed. In addition, our products have good toughness. If warpage occurs, it will flatten if it is placed for another 10 minutes.

2) Thermal sublimation paper before printing, because of its strong water absorption, to keep in the sealed bag. When printing, do not put it upside down, and the printing surface must face up

2) Thermal sublimation paper before printing, because of its strong water absorption, to keep in the sealed bag. When printing, do not put it upside down, and the printing surface must face up

Q: Are you a factory or not?

A: yes,we are factory,with two coating line.add:Industrial Concentration Zone, Yunting Street, Jiangyin City

you are welcome to visit us.

Q: Why the price changes?

A: The exchange rate changes. Firstly, it depends on the exchange rate,secondly,if you order a large amount, it can reduce our

costs, the price would be a little cheaper. but remember A penny a minute cargo.

Q: What printer and ink your paper suits?

A: Normal Inkjet Printer; All water-based Sublimation ink.

Q: What's your transfer rate?

A: Over 98%.( Fast dry series& quick dry series& sticky series )

A: yes,we are factory,with two coating line.add:Industrial Concentration Zone, Yunting Street, Jiangyin City

you are welcome to visit us.

Q: Why the price changes?

A: The exchange rate changes. Firstly, it depends on the exchange rate,secondly,if you order a large amount, it can reduce our

costs, the price would be a little cheaper. but remember A penny a minute cargo.

Q: What printer and ink your paper suits?

A: Normal Inkjet Printer; All water-based Sublimation ink.

Q: What's your transfer rate?

A: Over 98%.( Fast dry series& quick dry series& sticky series )

Похожие товары

Распродажа высококачественного самоклеящегося стикера

6 480,38 ₽ - 7 344,43 ₽

Высококачественная желтая бумага с силиконовым покрытием для теплопередачи, 140 г, китайский завод, большой рулон

41,05 ₽ - 43,21 ₽

Тонкий силиконовый виниловый рулон 0,2-1 мм Толщина силиконовый лист рулоны цвета и размеры могут быть настроены

486,03 ₽ - 702,05 ₽

Заводская низкая цена, A3 размер, золото, Uv, Dtf Ab, ПЭТ-пленка, рулон для УФ-рулонного принтера

Высококачественная термостойкая желтая бумага 140 г с китайской фабрикой

41,05 ₽ - 43,21 ₽

УФ-переводная печать, рулон пленки для футболки

3 780,22 ₽ - 3 888,23 ₽

Радужный голографический теплопередающий винил для одежды

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $