Трубчатые стеклянные флаконы боросиликатное стекло типа I для

- Категория: >>>

- Поставщик: Shandong Pharmaceutical Glass Co. Ltd.

Сохранить в закладки 1600404564212:

Описание и отзывы

Характеристики

Product Description

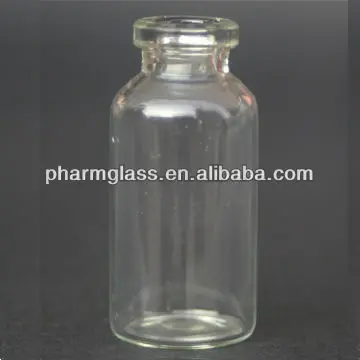

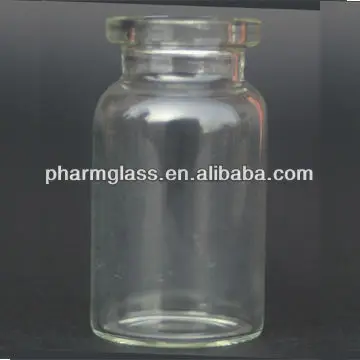

Moulded vs Tubular Glass Vials

Glass vials used to package pharmaceutical preparations are made from one of three glass types: Type I, Type II and Type III. Most parenteral and other non-oral drug products being packaged in Type I glass.This glass type, containing significant amounts of boric oxide, aluminium oxide, and alkali and/or alkaline earth oxides, benefits from high hydrolytic and thermal shock resistance. Type I glass vials can be made from either Tubular Glass or Moulded Glass.

How are they made?

Moulded Glass Vials are manufactured by cutting measured gobs from molten glass and feeding them into a mould. The vial shape is formed using a Press and Blow process or a Blow and Blow process. After the vial is made it is passed through an annealing lehr. Tubular Glass Vials are hot-formed from a continuous length of Type I glass tubing.The neck is formed first using a flame and tool to create the perfect shape, after which heat is precisely applied to allow separation of the new vial from the continuous length of tubing, thus forming the base and determining the height of the vial. Tubular glass vials, like moulded vials are also passed through an annealing lehr to reduce stress caused by the hot-forming process.

Glass vials used to package pharmaceutical preparations are made from one of three glass types: Type I, Type II and Type III. Most parenteral and other non-oral drug products being packaged in Type I glass.This glass type, containing significant amounts of boric oxide, aluminium oxide, and alkali and/or alkaline earth oxides, benefits from high hydrolytic and thermal shock resistance. Type I glass vials can be made from either Tubular Glass or Moulded Glass.

How are they made?

Moulded Glass Vials are manufactured by cutting measured gobs from molten glass and feeding them into a mould. The vial shape is formed using a Press and Blow process or a Blow and Blow process. After the vial is made it is passed through an annealing lehr. Tubular Glass Vials are hot-formed from a continuous length of Type I glass tubing.The neck is formed first using a flame and tool to create the perfect shape, after which heat is precisely applied to allow separation of the new vial from the continuous length of tubing, thus forming the base and determining the height of the vial. Tubular glass vials, like moulded vials are also passed through an annealing lehr to reduce stress caused by the hot-forming process.

What are the differences?

Visual differences

Tubular glass vials have a smooth, even surface and a thin, uniform wall thickness. They have a relatively flat base compared tothe more concave base of a moulded vial. Due to a less easily-controlled manufacturing process moulded glass vials have a less uniform wall thickness and uneven surface.

Moulded glass vials can be identified by markings on their bases called punt marks. These markings will usually include a mould number and a manufacturer’s mark: a symbol unique to the company who manufactured the vial.

Price difference

Due to the challenges of their respective manufacturing processes Tubular glass vials tend to be priced lower for smaller vial sizes, whilst Moulded glass vials become cheaper for large vial sizes, around 20ml and above.

Differences in performance

If you are planning to freeze dry product within the vial, Tubular glass vials are better-suited to lyophilisation (freeze drying)

as they provide more consistent heat-transfer as a result of a thinner and flatter base.

Their thinner and more even wall structure also allows for greater clarity, ideal for visual inspection of the contents.

Conclusion

Both Moulded and Tubular Type I borosilicate glass vials are suitable for a variety of pharmaceutical applications, including injectable preparations.

Reasons for choosing one manufacturing method over another may come down to how you plan to use the vials, your historic preferences, or price sensitivity.

If you’re unsure which vial you should be using, please contact us and our experienced team will be happy to help.

Visual differences

Tubular glass vials have a smooth, even surface and a thin, uniform wall thickness. They have a relatively flat base compared tothe more concave base of a moulded vial. Due to a less easily-controlled manufacturing process moulded glass vials have a less uniform wall thickness and uneven surface.

Moulded glass vials can be identified by markings on their bases called punt marks. These markings will usually include a mould number and a manufacturer’s mark: a symbol unique to the company who manufactured the vial.

Price difference

Due to the challenges of their respective manufacturing processes Tubular glass vials tend to be priced lower for smaller vial sizes, whilst Moulded glass vials become cheaper for large vial sizes, around 20ml and above.

Differences in performance

If you are planning to freeze dry product within the vial, Tubular glass vials are better-suited to lyophilisation (freeze drying)

as they provide more consistent heat-transfer as a result of a thinner and flatter base.

Their thinner and more even wall structure also allows for greater clarity, ideal for visual inspection of the contents.

Conclusion

Both Moulded and Tubular Type I borosilicate glass vials are suitable for a variety of pharmaceutical applications, including injectable preparations.

Reasons for choosing one manufacturing method over another may come down to how you plan to use the vials, your historic preferences, or price sensitivity.

If you’re unsure which vial you should be using, please contact us and our experienced team will be happy to help.

Company Description

We, established in 1970, the leading manufacturer of pharma glass packaging in China with 4300employees, we are public company listed in Shanghai Exchange Stock, our yearly sales amount is around USD428million, exported to 90countries with yearly export amount USD160million, we have 23furnaces to make different kinds of glass, the following is our Production Range:

Re: Soda-lime glass in four colors, like clear, amber, cobalt blue, green.

1, Mouled injection glass vial, type II,III, size from 5ml to 500ml.

2, Amber glass bottle, type II,III, size from 5ml to 1000ml. Certainly including j-cap bottle, and flat bottles.

3, Costmetic bottle: 1ml to 200ml, like nail polish bottle, glass jar for cream, perfulm bottle, oil bottle, etc.

4, Food bottle and beverage bottle: 20ml to 500ml.

1, Mouled injection glass vial, type II,III, size from 5ml to 500ml.

2, Amber glass bottle, type II,III, size from 5ml to 1000ml. Certainly including j-cap bottle, and flat bottles.

3, Costmetic bottle: 1ml to 200ml, like nail polish bottle, glass jar for cream, perfulm bottle, oil bottle, etc.

4, Food bottle and beverage bottle: 20ml to 500ml.

Re:Borosilicate Glass in clear color:

1, Moulded glass bottle/vials for injection, type I, size from 7ml to 500ml.

2, Glass baby feeding bottles.

3, Glass tubing, tubular glass vial, ampoules.

4, Dental cartridge, insulin glass vial/cartridge, prefilled syringe.

Re: Rubber and plastic products we also produce.

1, Rubber stopper and flip off cap for injection glass vial.

2, HDPE plastic bottle.

3, Plastic cap and dropper for dropper bottles.

4, Rubber disc liner for IV packing products.

Re: The relative produce

1, Glass pippete for dropper bottle,

2, Plastic cap and inner cap for boston round bottle.

3, CRC cap for tablet bottles.

1, Moulded glass bottle/vials for injection, type I, size from 7ml to 500ml.

2, Glass baby feeding bottles.

3, Glass tubing, tubular glass vial, ampoules.

4, Dental cartridge, insulin glass vial/cartridge, prefilled syringe.

Re: Rubber and plastic products we also produce.

1, Rubber stopper and flip off cap for injection glass vial.

2, HDPE plastic bottle.

3, Plastic cap and dropper for dropper bottles.

4, Rubber disc liner for IV packing products.

Re: The relative produce

1, Glass pippete for dropper bottle,

2, Plastic cap and inner cap for boston round bottle.

3, CRC cap for tablet bottles.

GOOD QUALITY

ISO STANDARD

SAFETY PACKING

Похожие товары

Производить 0 сахара и 0 жира monster 330 мл энергетический напиток витаминный напиток

Набор из 6 милых съемных магнитных деталей, плюшевые мягкие игрушки-животные для детей

QY Amazon, Лидер продаж, высокое качество, 6 шт./компл., ПВХ, Люка Альберто, морской монстр, экшн-фигурки, игрушки

2,50 $ - 3,40 $

Высококачественный 3D Забавный сборный пазл, игрушки, детали для игрушечного автомобиля

0,50 $ - 0,65 $

Металлический кнопочный переключатель ONPOW GQ22-A-11Y/21/S

EN S355J2WP Corten устойчивая к атмосферным воздействиям стальная пластина s355jowp corten от профессионального поставщика стали для

700,00 $ - 950,00 $

Игла с тупым кончиком для наполнителей

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $