Горизонтальная гипсовая Порошковая печь линия по производству гипса вращающаяся для гипсового порошка

- Категория: >>>

- Поставщик: Gongyi Derui Machinery Co. Ltd.

Сохранить в закладки 1600405008049:

Описание и отзывы

Характеристики

Gypsum Powder Rotary Kiln

Product introduction and application

This series of rotary kiln is the large-size advanced international calcining kiln & furnace which is developed by our company and many scientific research institutes such as Beijing General Reserch Institute of Mining & Metallurgy, Changsha Research Institute Of Mining & Metallurgy, Suzhou Sinoma Reserch Institute of Non-metallic Mining Industry, etc. Compared with the rotary kiln with the same specification made by the traditional technology, this series of torary kiln can make the production capacity increase by 30%, make the heat consumption reduce by 40% and make the discharged flue gas temperature<250 °C , so it is convenient for collecting dust and meeting the modern environment protection needs about energy saving and consumption reducing. This rotary kiln is widely used for extracting nickel from laterite, calcining the activated limestone, oxidized pellet, magnesium oxide, aluminum oxide, titanium dioxide, etc.

Advantage Of Rotary Kiln

1.High Automation Level

Its pre-heater with low-pressure loss can improve preheating effect efficiently. After preheating, the resolution ratio of the lime-stones can reach 20~25% when they enter the kiln. Besides, the lime-stones, with fine fraction about 10~15mm, can be used directly.

2.Waste Heat be Reused Effectively

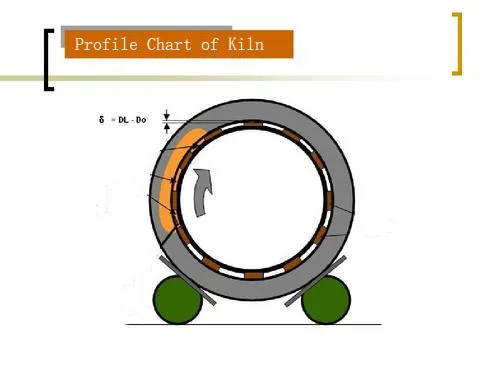

The two sides of the reliable rotary kiln are sealed by the combined scales, which can make the air leakage coefficient less than 10%. Composite refractory materials should be used in order to reduce the loss of radiant heat.

3.Low Energy Consumption

The filling vertical cooler, round or square, can be zoned-ventilation, which can make the temperature of lime-stones in the cooler at about 80°C. As a result, it is very convenient to transport and store. It can also pre-heater the secondary air up to the temperature above 900°C, then the waste heat can be recycled to reduce energy consumption.

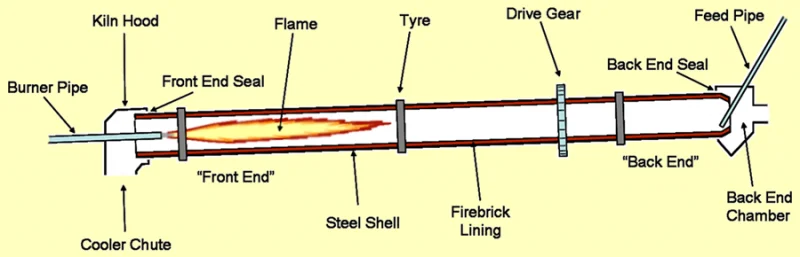

Working Principle

Derui Rotary kiln cylinder composed of steel plate, cylinder body with build by laying bricks or stones of refractory lining, and horizontal line into slope, three belting leather in each block supporting device, in the material near the end belting leather across the inner cylinder with tangential spring plate fixed on a big gear ring, which is a small gear meshing. During normal operation, the main drive motor is transmitted to the open-type gear device by the main drive motor, which drives the rotary kiln.Materials are calcined from the end of the kiln. Due to the effect of tilting and slow rotation of the cylinder, the material is along the circumference of a circle and tumbling along the axial direction (from high to low) mobile, continue to complete the process, and generate the clinker kiln hood into the cooling machine cooling.The fuel is sprayed into the kiln by the kiln head, and the waste gas and materials produced in the furnace are exchanged for impact crusher, which is exported by the kiln tail.

Model(m) | Diameter (m) | Length(m) | Slope(%) | Capacity(t/h) | Rotate Speed (r/min) | Motor Power(kw) | Weight(T) |

φ1.4×33 | 1.4 | 33 | 3 | 0.9-1.3 | 0.39-3.96 | 18.5 | 47.5 |

φ1.6×33 | 1.6 | 33 | 4 | 1.2-1.9 | 0.26-2.63 | 22 | 50 |

φ1.6×36 | 1.6 | 36 | 4 | 1.2-1.9 | 0.26-2.63 | 22 | 52 |

φ1.8×32 | 1.8 | 32 | 4 | 1.9-2.4 | 0.16-1.62 | 30 | 78.2 |

φ1.8×45 | 1.8 | 45 | 4 | 2.8-3.34 | 0.21-2.11 | 30 | 95.2 |

φ1.9×36 | 1.9 | 36 | 3.5 | 1.2-1.7 | 0.29-2.93 | 30 | 86.3 |

φ1.9×45 | 1.9 | 45 | 3.5 | 1.65-2.5 | 0.29-2.93 | 37 | 109 |

φ2.2×48 | 2.2 | 48 | 3 | 1.9-2.1 | 0.98-2.93 | 55 | 141 |

φ2.5×40 | 2.5 | 40 | 3.5 | 6.0-7 | 0.44-2.44 | 55 | 139.61 |

φ2.5×50 | 2.5 | 50 | 3.5 | 7.0-8.0 | 0.48-1.44 | 55 | 179.6 |

φ2.5×54 | 2.5 | 54 | 3.5 | 8.0-8.6 | 0.48-1.44 | 55 | 196.29 |

φ2.7×42 | 2.7 | 42 | 3.5 | 10.0-11.0 | 0.10-1.52 | 55 | 198.5 |

φ2.8×44 | 2.8 | 44 | 3.5 | 11-12.5 | 0.80-2.39 | 55 | 198.6 |

φ3.0×45 | 3 | 45 | 3.5 | 13.3-16.9 | 0.5-1.35 | 55 | 223 |

φ3.2×52 | 3.2 | 52 | 3.5 | 16-18.5 | 0.48-2.44 | 110 | 278 |

Pre-sale services,we do

Act as a good adviser and assistant of clients; enable them to get rich and generous returns on their investments;

1. Select equipment model;

2.Sdeign and manufacture products according to clients' special requirement;

3. Train technical personnel for clients.

Services during the sale,we do

Respect clients; devote ourselves to improving the total value of clients.

1. Pre-check and accept products ahead of delivery;

2. help clients to draft solution.

After-sales service,we do

Provide considerate services to minimize clients' worries.

1. Assist clients to prepare for the first construction scheme;

2. Install and debug the equipment;

3. Train the first-line operators on site;

4. Examine the equipment regularly;

5. Take initiative to eliminate the troubles rapidly at site;

6. Distribute the guarantee fittings door-to-door;

7.provide perfect service;

8. Provide technical exchanging;

9. Provide maintenance for big items.

Q:What is the MOQ?

R:MOQ is 1 set,we allow OEM and sample order,but the cost are paid by your side.

Q: Where is your factory located? How can I visit there?

R: Our factory is located in Zhengzhou City, Henan Province, China.Contact us ahead before you go visit,then we can fully arrange the schedule and meet you.Welcome to visit us!

Q: What is the warranty time of your products?

R: The warranty time is 12 months from the date of the commissioning.After the warranty, any questions and needs,please contact us.

Q: How does your factory do regarding quality control?

R: All products have to pass strict inspection before they ship out.And we have gained ISO9001:2008 authentication.If you need other certificate and quality control,please contact us.

Our Company Philosophy

Best Quality for Market

Perfect Service for Clients

Scientific Management for Benefits

Good Credit for Development

Gongyi Derui Machinery Co., LTD entered the mechanical industry from the beginning of the 1980’s, earlier than most factories. With the company philosophy these years, our products are sold to many customers from home and abroad, popular in India, Russia, Kazakhstan, Africa, South America, Mid-East, Southeast Asia, and almost 30 countries and areas. And it is our honor to make a contribution of to the development of these countries.

Growth is only a process, and the brilliance is the new beginning. In order to respond positively to the good policy of The Belt and Road, we will, as always, provide higher and higher quality products and service, to win more and more acclamation and respect for Chinese national industry. Review ourselves with serious attitude, and win the trust with excellent quality. We sincerely hope to take win-win cooperation with entrepreneurs and companies all over the world, to develop the market together.

Похожие товары

Производитель канадской хлопчатобумажной постельной ткани и для

Пластиковый гранулированный фильтр из оцинкованной полипропиленовой сетки пищевого класса

Лидер продаж, Машина Для Производства гипсового порошка Zenith, производственная линия гипсового порошка

Транзисторы выхода-23 MMBTSC1623-L5

Лидер продаж, контроллер скорости электродвигателя переменного тока гарантированного качества

Новейший дизайн, одноразовая Игла Micro Cannula для наполнителя

Пользовательские Наружные 3D подсвеченные номера адресов из нержавеющей стали, светодиодная подсветка, высота 15 см, табличка с цифрами дома

Новые поступления

Новинки товаров от производителей по оптовым ценам