Промышленная Центробежная керамическая распылительная сушилка модели LPG

- Категория: >>>

- Поставщик: Changzhou Yinuo Drying Engineering Co. ltd.

Сохранить в закладки 1600405175067:

Описание и отзывы

Характеристики

General discription

The spray drying is the widest used technology in the liquid shaping technology and in the drying industry.

It is most suitable for producing powder, particle, or block solid products from materials of solution, emulsion, soliquoid and pumpable paste states. Therefore, when the particle size and distribution of the final products, their residual water contents, the stocking density and the particle shape meet the precision standards, the spray drying is one of the most desired technologies.

Features

1, High speed of drying. After the spraying of he material liquid, the surface area of the material will be increased greatly. In the hot-air flow, 95%-98% of water can be evaporated at a moment. The time of completing the drying needs only several seconds.

2, It is especially suitable for drying the heat sensitive materials. It’s final products own the good uniformity, mobility, dissolving capacity. And the final products are high in purity and good in quality.

3, The production procedure is simple and the operational control is easy. The liquid with the moisture contents 40-60%(for special materials, the contents may reach 90%) can be dried into power or particle products once a time. After the drying, there is no need for smashing of sorting, so as to reduce the operation procedures in the production and enchance the purity. The product particle diamenters, looseness and water contents can be adjusted through changing the operation condition in a certain scope. It is very convenient to carry out the control and management.

Technical parameters

type | LPG | |||||||

5 | 25 | 50 | 100 | 150 | 200-3000 | |||

Inlet temperature | ≤ 350°C | |||||||

Outlet temperature | 80-90°C | |||||||

evaporate capacity (kg/h) | 5 | 25 | 50 | 100 | 150 | 200-3000 | ||

driving type | compressed air drive | mechanical drive | ||||||

Rotate speed | 25000 | 22000 | 21500 | 18000 | 18000 | 15000 | ||

diameter of atomizer tray (mm) | 50 | 120 | 120 | 120 | 150 | 180-340 | ||

heating source | electricity | electricity | electricity +steam+fuel oil+coal gas | electricity +steam | electricity +steam+fuel oil+coal gas | To be solved by users | ||

Electric-heating power (kw) | 9 | 45 | 60 | 81 | 99 |

| ||

Dried powder recovery rate (%) | ≥ 95 | ≥ 95 | ≥ 95 | ≥ 95 | ≥ 95 | ≥ 95 | ||

Installation size | A(mm) | 1000 | 1290 | 1730 | 2500 | 2800 | according to practical needs | |

B(mm) | 2100 | 3410 | 4245 | 5300 | 6000 | |||

C(mm) | 2300 | 4260 | 4645 | 6000 | 6700 | |||

φ D(mm) | 1060 | 1800 | 2133 | 2560 | 2860 | |||

E1(mm) | 1050 | 1200 | 1640 | 2100 | 2180 | |||

E2(mm) | 1050 | 1200 | 1640 | 2100 | 2180 | |||

F(mm) | 750 | 1000 | 1250 | 1750 | 1970 | |||

G(mm) | 530 | 1700 | 1750 | 1930 | 2080 | |||

H(mm) | 530 | 1300 | 1800 | 2600 | 3050 | |||

I(mm) | 530 | 1550 | 1600 | 1780 | 1960 | |||

Похожие товары

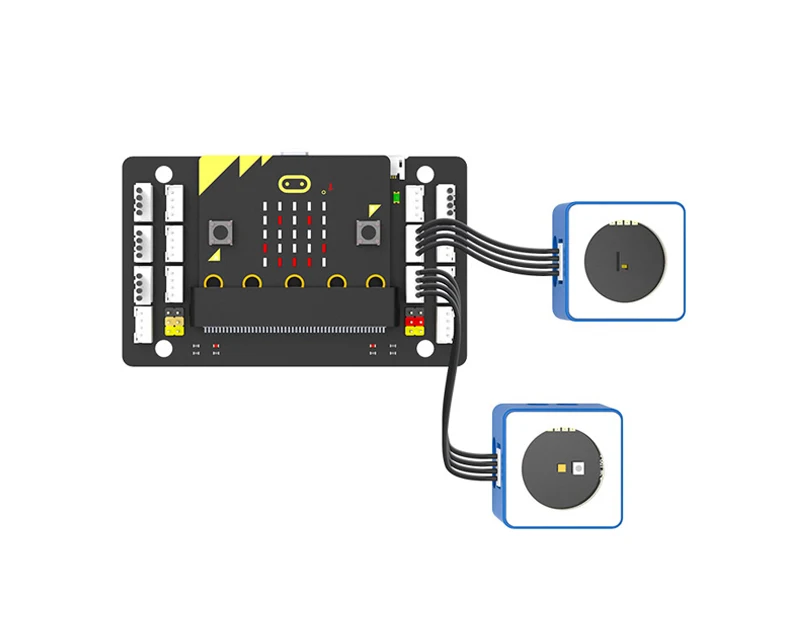

Плата расширения датчика с кабелем PH2.0, для соединения с различными датчиками, совместима с различными модулями

2021 коммерческий латунный Смеситель для раковины, смеситель, смеситель для кухни sus304, смесители для кухни с вытяжным распылителем

Заводская поставка, запасные части для дизельного двигателя 3913433, поддержка вентилятора

Лучшие Продажи Роланд Eco-Solvent Макс Струйный Плоттер Картридж Подключи И Играй

Пищевая промышленность санитарная химического 100 галлонов резервуар из нержавеющей стали электрическое Отопление рубашкой 3000L алкоголя 300 л резервуар для смешивания

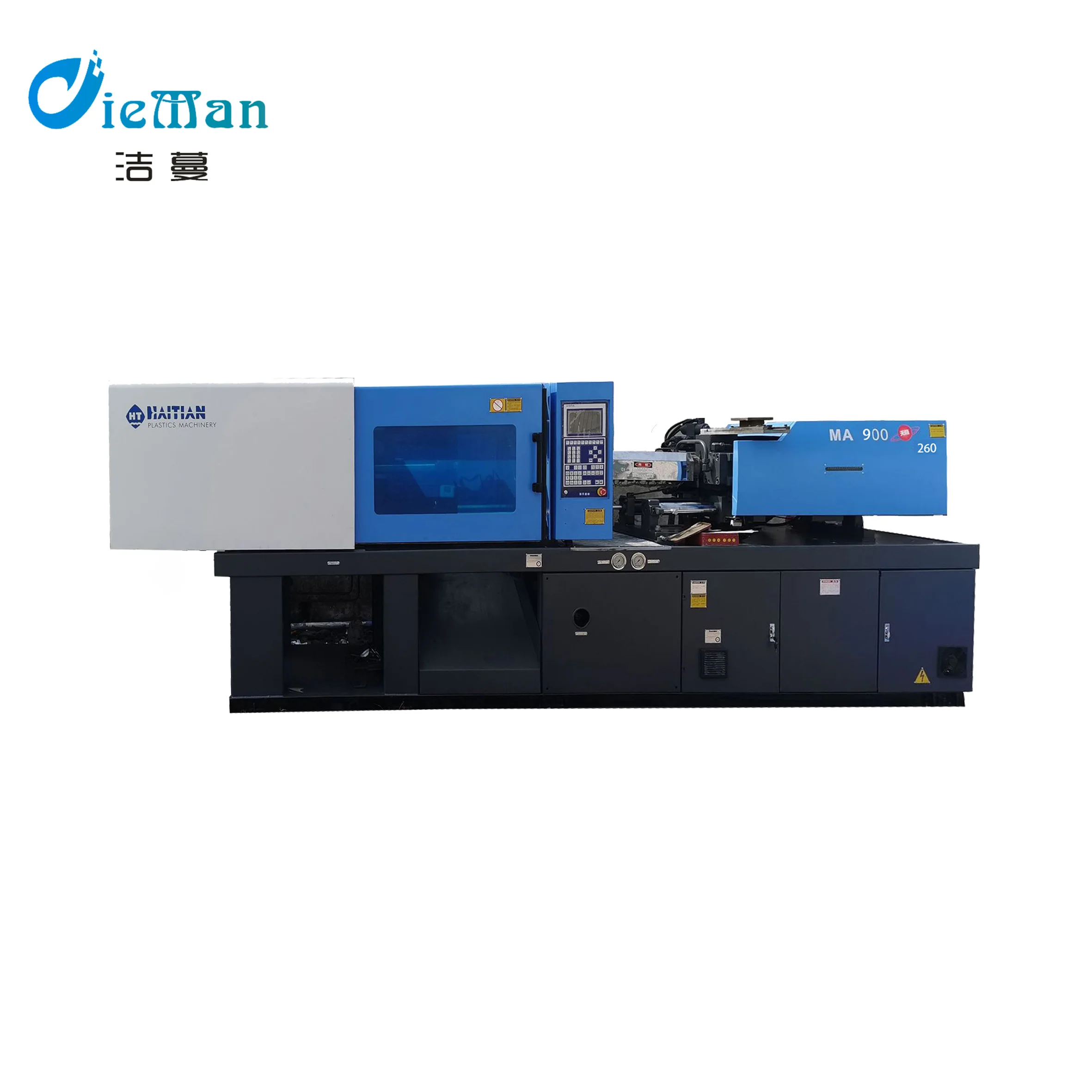

Пластиковый Электрический переключатель и розетка 90T, производство, производство, литье под давлением

Пищевой санитарный Химический бак из нержавеющей стали объемом 100 галлонов с электрическим нагревом, с оболочкой, 300 л спирта, емкость для смешивания объемом литров

Новые поступления

Новинки товаров от производителей по оптовым ценам