Токарный станок с ЧПУ обработка cermet VBMT160404 токарный вставка для деталей станка

- Категория: >>>

- Поставщик: Zhuzhou Uko Cemented Carbide Co. Ltd.

Сохранить в закладки 1600406012909:

Описание и отзывы

Характеристики

Product Description

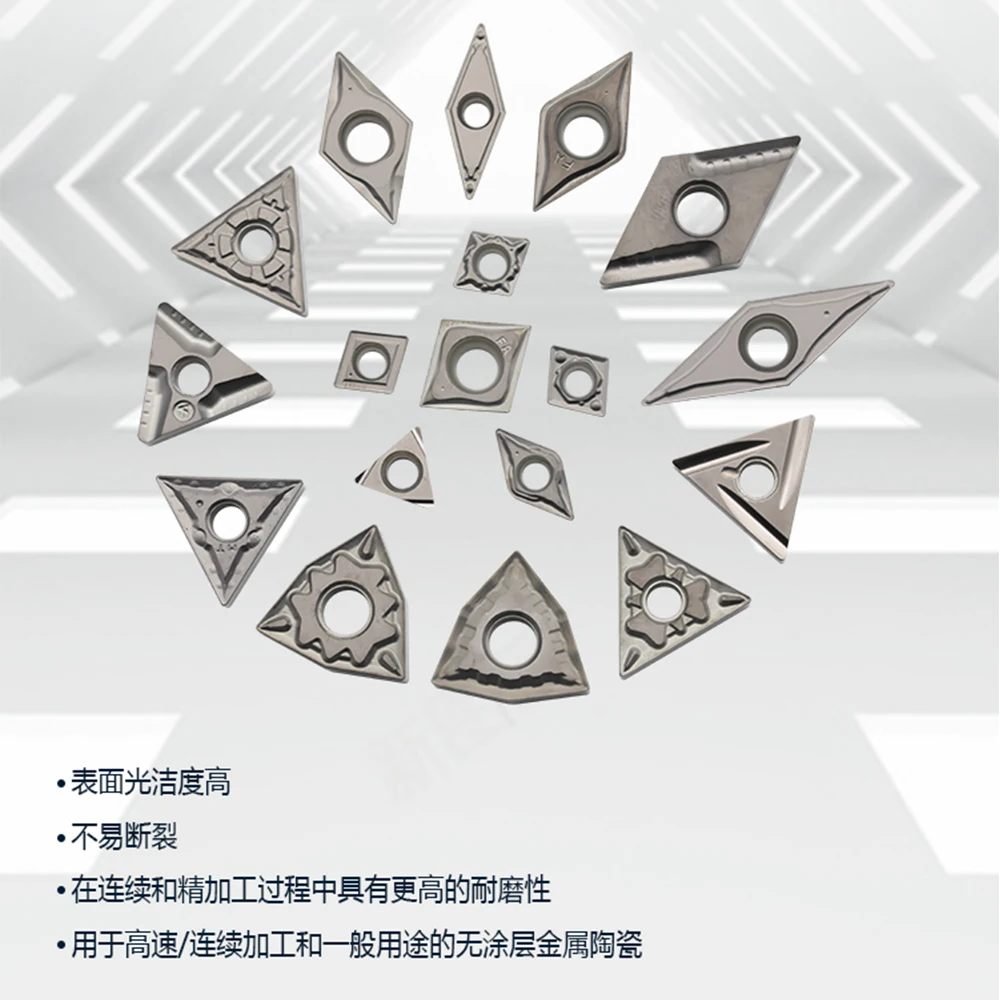

Our Advantages

1. Minimize deviation in insert quality

Ensure stabilized lifespan

2. Excellent balance between material grade and chip breaker

Maximized machinability and tool life

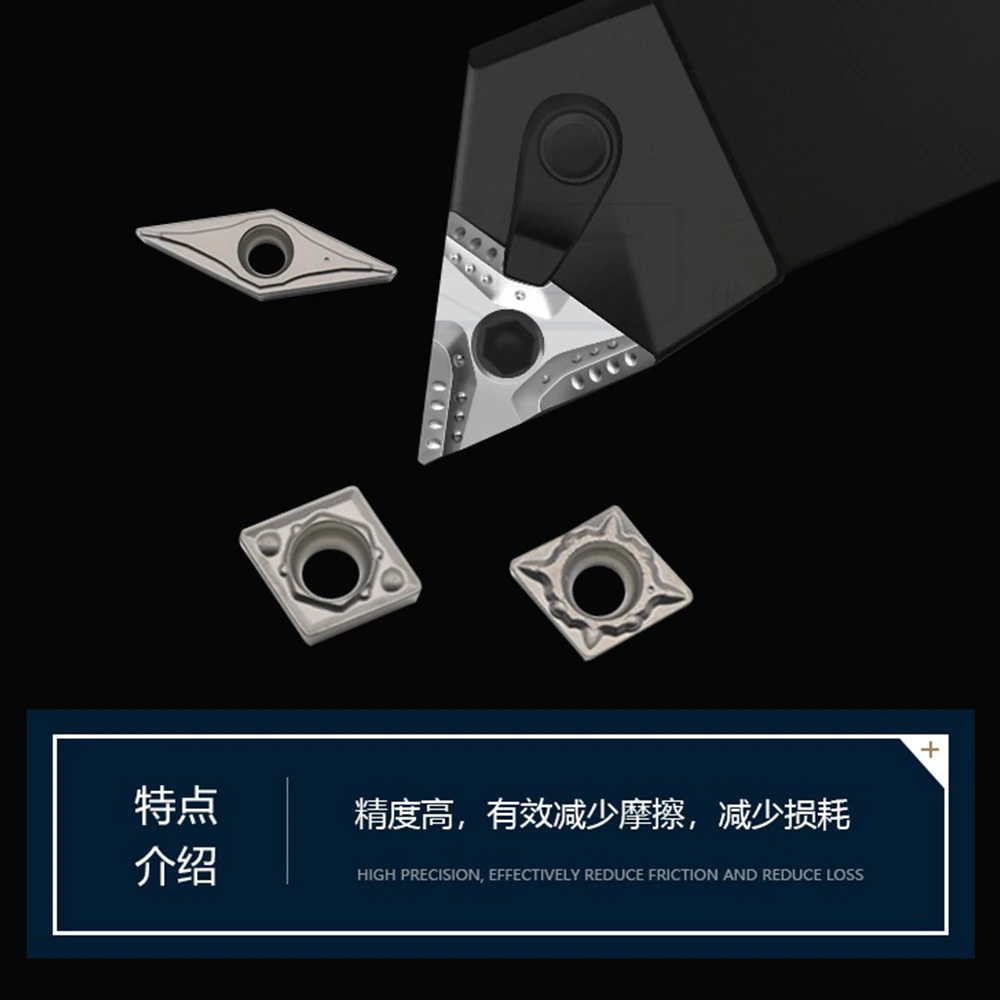

3. Optimal cutting edge

Minimizes the degrading of surface roughness of the machined product

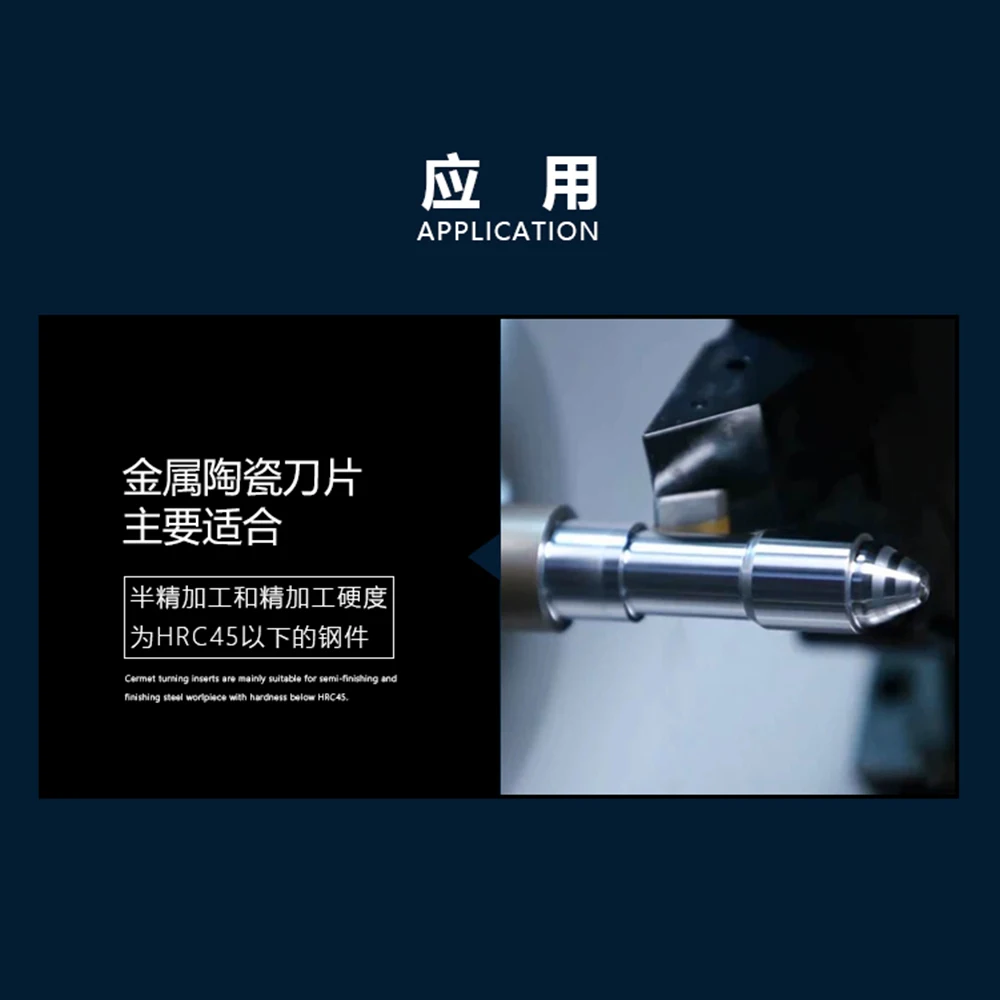

4. Applicable on workpiece made of carbon steel, bearing steel, alloy steel and sintered alloy

Increased versatility when the workpiece is changed

Ensure stabilized lifespan

2. Excellent balance between material grade and chip breaker

Maximized machinability and tool life

3. Optimal cutting edge

Minimizes the degrading of surface roughness of the machined product

4. Applicable on workpiece made of carbon steel, bearing steel, alloy steel and sintered alloy

Increased versatility when the workpiece is changed

Specification

Type | Dimension | ||||||||

LE | IC | S | d | r | |||||

VBMT160404-FG | 16.5 | 9.525 | 4.76 | 4.4 | 0.4 | ||||

VBMT160408-FG | 16.5 | 9.525 | 4.76 | 4.4 | 0.8 | ||||

VBMT160404-HQ | 16.5 | 9.525 | 4.76 | 4.4 | 0.4 | ||||

VBMT160408-HQ | 16.5 | 9.525 | 4.76 | 4.4 | 0.8 | ||||

VBMT160404-VF | 16.5 | 9.525 | 4.76 | 4.4 | 0.4 | ||||

VBMT160408-VF | 16.5 | 9.525 | 4.76 | 4.4 | 0.8 | ||||

Details Images

Customer Usage Scenarios

Top Equipment

Packing & Delivery

Packing Details : 10 PCS to a box

Delivery Details : For stocked items, we will deliver the products within 3-5 days after payment confirmed.

Tool Holder Matching

Our Company

Cermet inserts use FAQ

1. Worn face

Influence: Gradually changing workpiece size or surface finish

Reason: Line speed is too high, reaching tool life

Solution: Adjust processing parameters, such as reducing line speed and using more wear-resistant inserts

Reason: Line speed is too high, reaching tool life

Solution: Adjust processing parameters, such as reducing line speed and using more wear-resistant inserts

2. The insert broke

Influence: Sudden change in workpiece size or surface finish, sparks on the surface

Reason: Inappropriate parameter settings, inappropriate choice of insert material, poor workpiece rigidity, unstable blade clamping

Solution: Check whether the parameter setting is reasonable and select the corresponding tool according to the workpiece material

Reason: Inappropriate parameter settings, inappropriate choice of insert material, poor workpiece rigidity, unstable blade clamping

Solution: Check whether the parameter setting is reasonable and select the corresponding tool according to the workpiece material

3. Severe fracture

Influence: Sudden unpredictable conditions occur, resulting in scrap of tool holders or defective and scrapped workpieces

Reason: The processing parameters are set incorrectly, and the vibrating workpiece or insert is not installed in place.

Solution: Set reasonable processing parameters, should reduce the feed amount and reduce the chip selection of the corresponding processing inserts, strengthen the rigidity of the workpiece and the insert.

Reason: The processing parameters are set incorrectly, and the vibrating workpiece or insert is not installed in place.

Solution: Set reasonable processing parameters, should reduce the feed amount and reduce the chip selection of the corresponding processing inserts, strengthen the rigidity of the workpiece and the insert.

4. Scum tumor

Influence: Inconsistent workpiece size, poor surface finish, and fluff or burrs on the surface

Reason: Cutting speed is too low, feed is too low / not sharp enough

Solution: Increase cutting speed and use sharper inserts for feed

Reason: Cutting speed is too low, feed is too low / not sharp enough

Solution: Increase cutting speed and use sharper inserts for feed

Похожие товары

Водонепроницаемый силиконовый кошелек для монет с мультяшными персонажами

2,80 $

Bolsa модные женские туфли, с тиснением под крокодиловую кожу маленькие сумки через плечо из мягкой искусственной кожи подмышек сумки Женская сумочка на цепочке сумка

3,00 $ - 5,33 $

Потоковая ячейка

18 дюймов популярный Профессиональный сабвуфер

Военные игрушки, игровой набор, тяжелый пулемет, игрушка для продажи

Производитель профессионального колеса Запасное колесо сабвуферы заката аудио сабвуфер автомобиля с 10 дюймов НЧ-динамик

110,20 $ - 133,30 $

Взрослые мужские горные велосипеды с полной подвеской взрослые толстые шины bmx дорожные колеса 26 29 дюймов велосипеды для езды на велосипеде Горный велосипед

50,00 $ - 83,00 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $