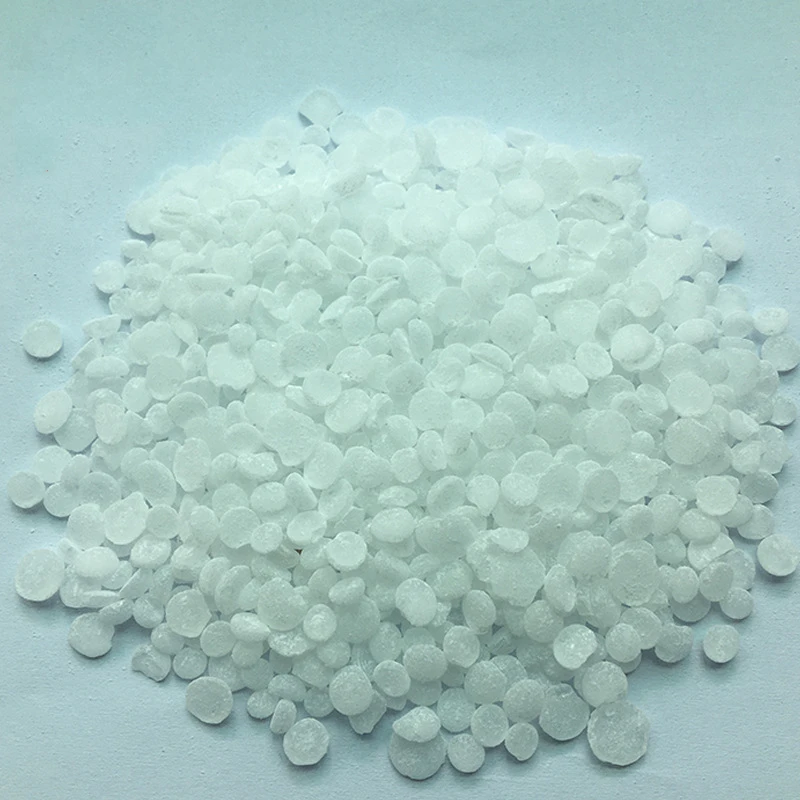

В наличии клейкая смола чистота 99.9% углеводородная Смола C9

- Категория: >>>

- Поставщик: Henan Yeedok Industry Co. Ltd.

Сохранить в закладки 1600406272192:

Описание и отзывы

Характеристики

Products Description

Petroleum resin is petroleum cracking by the by-product of C5, C9 distillate, after pretreatment, polymerization, distillation and other processes to produce a thermoplastic resin, it is not a polymer, but between the molecular weight of 300-3000 oligomer.

Specification

C9 | C5 | |

Color (in 50% Toluene) | from No 3 to No.6 | No.4-5 |

Soften Point (DC) | 80-90;100+/-5;110+/-5;120+/-5;130+/-5;over 130 | 80-90; 90-100; 100-110; 110-120 |

Acid value (mgKOH/g) | 0.5max | 0.5% max. |

Iodine value (g I2/100g) | 60-120 | 20/120 |

Ash value | 0.1% max | 0.1% max. |

PH value | 6-8 | / |

Application

Petroleum resin in different industries in the use of performance and role:

A.paint

Paint is mainly used high softening point OF C9 petroleum resin, DCPD resin, C5/C9 copolymer resin, paint added petroleum resin can increase paint gloss, improve paint film adhesion, hardness, acid resistance, alkali resistance.

B.rubber

Rubber mainly uses low softening point C5 petroleum resin, C5/C9 copolymer resin and DCPD resin. This kind of resin and natural rubber rubber particles have good mutual solubility, rubber vulcanization process does not have a big impact, adding petroleum

resin in rubber can play the role of stickiness, reinforcement, softening. In particular, the addition of C5/C9 copolymer resin can not only increase the adhesive force between colloidal particles, but also improve the adhesive force between colloidal particles and cord, which is suitable for high requirements of rubber products such as radial tires.

C. Adhesive industry

Petroleum resin has good adhesion, adding petroleum resin in adhesive and pressure sensitive adhesive tape can improve adhesive adhesion, acid resistance, alkali resistance and water resistance, and can effectively reduce the production cost.

D. ink industry

Printing ink with petroleum resin, mainly high softening point C9 petroleum resin, DCPD resin. The addition of petroleum resin in the ink can play a color, fast drying, brightening effect, improve the printing performance.

E. Coating industry

Road signs and road marking paint with petroleum resin on the concrete or asphalt pavement has good adhesion, and wear resistance and good resistance to water, has a good affinity with the inorganic compound, easy coating, good weather resistance, quick

drying, strong degree is high, and can improve the physical and chemical properties of the layer, improve the uv resistance and weatherability. Petroleum resin road sign paint gradually tends to mainstream, demand increased year by year.

F. other

Resin has a certain unsaturated, can be used for paper adhesive, plastic modification agent.

A.paint

Paint is mainly used high softening point OF C9 petroleum resin, DCPD resin, C5/C9 copolymer resin, paint added petroleum resin can increase paint gloss, improve paint film adhesion, hardness, acid resistance, alkali resistance.

B.rubber

Rubber mainly uses low softening point C5 petroleum resin, C5/C9 copolymer resin and DCPD resin. This kind of resin and natural rubber rubber particles have good mutual solubility, rubber vulcanization process does not have a big impact, adding petroleum

resin in rubber can play the role of stickiness, reinforcement, softening. In particular, the addition of C5/C9 copolymer resin can not only increase the adhesive force between colloidal particles, but also improve the adhesive force between colloidal particles and cord, which is suitable for high requirements of rubber products such as radial tires.

C. Adhesive industry

Petroleum resin has good adhesion, adding petroleum resin in adhesive and pressure sensitive adhesive tape can improve adhesive adhesion, acid resistance, alkali resistance and water resistance, and can effectively reduce the production cost.

D. ink industry

Printing ink with petroleum resin, mainly high softening point C9 petroleum resin, DCPD resin. The addition of petroleum resin in the ink can play a color, fast drying, brightening effect, improve the printing performance.

E. Coating industry

Road signs and road marking paint with petroleum resin on the concrete or asphalt pavement has good adhesion, and wear resistance and good resistance to water, has a good affinity with the inorganic compound, easy coating, good weather resistance, quick

drying, strong degree is high, and can improve the physical and chemical properties of the layer, improve the uv resistance and weatherability. Petroleum resin road sign paint gradually tends to mainstream, demand increased year by year.

F. other

Resin has a certain unsaturated, can be used for paper adhesive, plastic modification agent.

Packaging

25 kgs in plastic woven/paper bag,17tons without pallet or 17tons with pallet in the 20'FCL

Company Profile

Henan Yeedok Industry Co., Ltd. Located at Zhengzhou Jinshui Zone and covering an area of 10,000M2,is a Chemical high-tech group company with an integrated system of researching,development,production, marketing and sales ability. It mainly produces Inorganic Chemicals, Organic Chemicals, Food and Feed Additives. Our products are widely applied to detergent, water treatment, rubber, plastic, leather, tanning, textiles, paint, oil drilling, food, feeding and pharmaceutical. With ISO9001 quality management system, all our products are manufactured by strict procedures. With the advanced test equipments in our Lab, all shipments are tested carefully before delivery to assure the quality consistency. The quality standard for each customer is established. All the sample and shipment lots have been filed detailed and be able to traced. Through many years of development, our company has become a large-scale enterprise with research, production,assembly and marketing capabilities. Guaranteeing stable and timely supply, credible quality and sincere service, our products sell well in both domestic and overseas markets. Our aim is to provide customers the high quality products, most competitive pricing, the shortest delivery time and the unequaled service. We pursue the management tenet of "Quality is Superior, Service is Supreme, Reputation is First", and will sincerely create and share success with all clients. We welcome you to contact us for more information and look forward to working with you!

FAQ

Q1.Are you a manufacturer or trading company?

A: We are a professional chemical manufacturer.

Q2. What's your payment terms?

A: T/T ,L/C based on different conditions.

Q3. What's your delivery time?

A: 7-15 days, according to client's request.

Q4. How about the validity of the products?

A: Guaranteed 3 years, Quality is stalbe.

Q5. What documents you provide?

A: Normally, we provide Commercial Invoice, Packing List, Bill of loading, COA , Health certificate and Origin certificate and other special requirements.

Q6. Can you proceed by our specification and package?

A: Definitely is available, any of your request about package can be customized.

Q7. Why did lots of customers choose us?

A: Good quality, competitive price and timely delivery time. And our products will give you an edge over your competitors.

A: We are a professional chemical manufacturer.

Q2. What's your payment terms?

A: T/T ,L/C based on different conditions.

Q3. What's your delivery time?

A: 7-15 days, according to client's request.

Q4. How about the validity of the products?

A: Guaranteed 3 years, Quality is stalbe.

Q5. What documents you provide?

A: Normally, we provide Commercial Invoice, Packing List, Bill of loading, COA , Health certificate and Origin certificate and other special requirements.

Q6. Can you proceed by our specification and package?

A: Definitely is available, any of your request about package can be customized.

Q7. Why did lots of customers choose us?

A: Good quality, competitive price and timely delivery time. And our products will give you an edge over your competitors.

Похожие товары

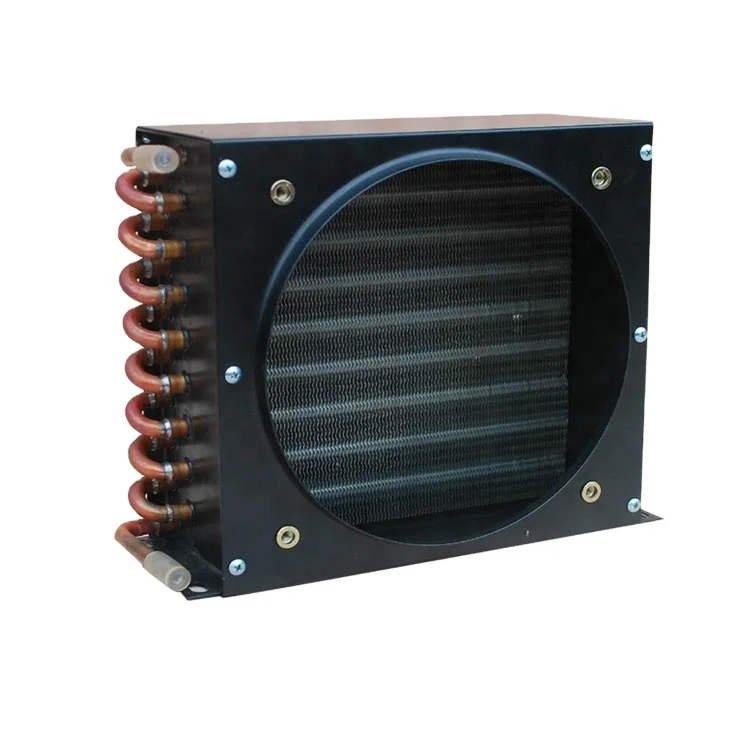

Теплосменное оборудование, медная катушка, алюминиевый ребристый конденсатор

Оконные козырьки, вентиляционные широкие дефлекторы для Suzuki Grand Vitara 1998-2005

Primingpumpassy для самосвала HD785-7 626-17-18240 6261-71-8240

Литье под давлением в масштабе 1:64, модель грузовика-контейнера из высококачественного сплава

17,50 $ - 19,00 $

Китайская фабрика, оптовая продажа, 100%, ручная роспись, современный стиль, рамка, Роскошный декор для гостиной, абстрактная картина маслом на холсте

19,90 $ - 39,90 $

Горячая Распродажа, глюкометр sugarno для измерения глюкозы в крови при диабете, датчик медицинского стандарта

7,92 $ - 8,35 $

Tcon тп. MT5522.PC821 Рабочая HV430QUB-N1A экран для 43 дюймов материнская плата

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $