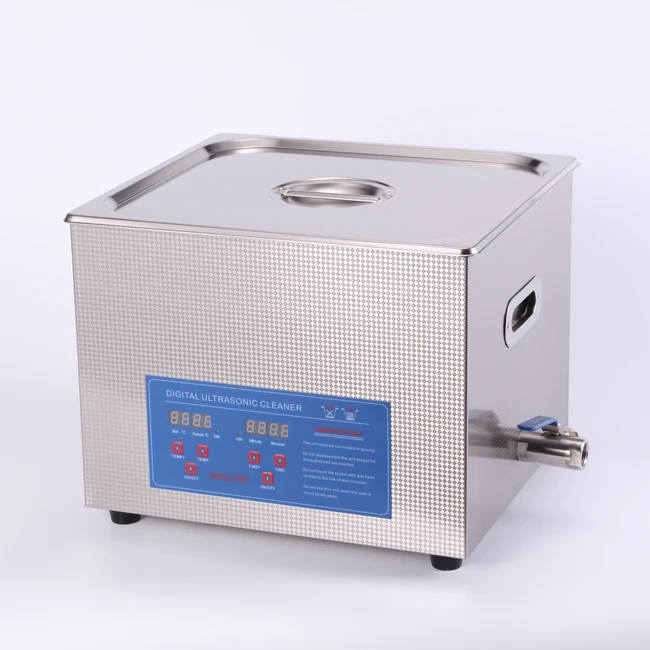

Ультразвуковая Очистительная Машина для лабораторий

- Категория: >>>

- Поставщик: Skymen Technology Corporation LimitedSkymen Limited

Сохранить в закладки 1600407093280:

Описание и отзывы

Характеристики

Filtration system SUS304 Stainless Industrial Ultrasonic Cleaning Machine Ultrasonic cleaner 360L for medical labs

| 1 | Model No. | JP-720G | ||

| 2 | Image |  | ||

| 3 | Ultrasonic model | Ultrasonic Frequency | 28,000 Hz/ 40,000Hz optional, or dual frequency | |

| Material | Stainless Steel SUS304 | |||

| Tank Capacity | 360 L | |||

| Timer | 1~99 hours adjustable | |||

| Heater | 20°C to 95°C adjustable | |||

| Machine voltage | 380V 3 phase | |||

| Generator voltage | AC 110V/220V | |||

| Ultrasonic Power | 0-3600W | |||

| Heating Power | 12000 W | |||

| Generator | 1 set | |||

| Washing basket | 1 pc | |||

| Caster | 4 pcs | |||

| Drainage | include | |||

| Cover | include | |||

| Oil skimmer | attached tank, pump | |||

| 4 | Packing | Tank Size | 1000*600*600mm( L x W x H ) | |

| Unit Size | 1170*770*815mm ( L x W x H ) | |||

| Package Size | 1280*1500*1000mm ( L x W x H ) | |||

| N.W/G.W | 207kg/280kg | |||

| Warranty | 1 year | |||

| 5 | Features | 1. Stainless steel SUS304 2. Power adjustable by clockwise, LED display for timer and heater seting, 3. Stainless steel washing basket and Lid, 4. ultrasonic cleaning solutions penetrate virtually any soil type including: oils, residues, solvents, pastes and chemicals and other contaminants are safely lifted and dispersed, leaving a surface appearance that is clean and free of particulate; even in crevasses and internal bores. | ||

| 6 | Application. | industry intrument,hardware instrument,scientific laboratory, automotive parts, motor, machine tool,etc. | ||

| 7 | Certificates | CE, ROHS, FCC, ISO9001:2008 | ||

Special Features:

1. stainless steel tank has resistance to wear and long work life.

Application:

-Scientific Labs:Eyeglass Frames;Lab Glassware;Optical&Contact Lenses;Pipettesscientific Instruments;Test tubes

-Industrial Manufacturing:Assemblies;Gears;Metal&Plastic Parts;Precision Bearings

-Electronic manufacturing:Capacitors;Ceramic Substrates;PC Boards;Packaging Components;Quartz Crystals

-Medical and Dental Lab:Burs;Blood Oxygenators;Dental Instruments;Syringe Parts;Surgical Instruments

-Jewelry Manufacturing:Chains;Charms;Coins;Intricate Settings;Precious Metals&Gemstones;Watches

If your company has other needs, you can choose the size that suits you according to the chart below

How ultrasonic cleaner works:

Electrical energy is converted into mechanical vibrations thanks to special elaborated transducers.These vibrations are transferred into the fluid through the walls of stainless steel.This creates tiny microscopic vacuum bubbles, which cause consecutive implosions (cavitation).The high-energy jets that are thus created can efficiently remove dirt from surfaces an materials placed in the cleaning bath.

Why we use filter(filtration cycle system)?

Cleaning of the manufacturing industry Cleaning of the manufacturing industry usually requires a large amount of solvent to remove grease and dust on the surface of the part. Usually, a large amount of solvent and detergent are used to remove the grease and dust on the surface of the part.

However, the use of solvents and detergents inevitably increases the amount of water, which increases the cost of cleaning and is not environmentally friendly.The circulation filtration system effectively reduces the cleaning cost, greatly reduces

the discharge of wastewater, and achieves the purpose of sustainable recycling of cleaning water.

Company profile

Here are the Skymen company.You can know more about us with the details.

FAQ:

What autoparts can be cleaned?

Resistors, capacitors, potentiometers, electronic tubes, radiators,

electromechanical components, connectors, semiconductor discrete devices,

electro-acoustic devices, laser devices, electronic display devices,

optoelectronic devices, sensors, power supplies, switches, micro motors

What are the Advantages of ultrasonic cleaners?

1. Convenient and time saving, saving manpower and saving time.

2. The ultrasonic cleaning machine is designed with multiple safety devices, electric drive, no gas generation, and is environmentally friendly. With advanced technology and an experienced design team, the ultrasonic cleaner is able to clean a variety of printheads.

Quality assurance CE and ISO9001.

3. With our own design and technology, our machines are designed to be highly efficient and clean, without damaging the cleaning components and for precise items.

4. We have our own independent technology research and development team as well as experienced design teams and skilled workers.

We are able to offer the highest quality machines at the factory price.

How do I choose frequency for my medical components?

Ultrasonic cleaning machines uses the working frequency of 28 kHz (with a ±2%sweep system)for autoparts. This has been determined as the most effective for cleaning components within the sectors described above, as it achieves the best cleaning without damaging any soft materials like aluminum, magnesium, brass etc. For cleaning requirements not specified above, we may occasionally recommend an alternative frequency, or where the quality requirements of the client are very particular and 40 kHz (sweep system ±2%)

Q: Are there any installation instructions after receiving the machine?

A: Yes, we provide the oretical and practical training for equipment operators of client companies to standardize operations and maximize equipment production efficiency.

Похожие товары

3 2-20L цифровой ультразвуковой очиститель JPS-60A 15l ультразвуковая стиральная машина для очистки инжектора

Хорошее качество 11l Многочастотные металлические детали ультразвуковой очистки ванны очиститель

GT SONIC 117L автозапчасти тип стиральной машины ультразвуковая очистка карбюратора очиститель

Ультразвуковой погружной преобразователь вибратор

Ультразвуковая стиральная машина Eco LP 20-точная очистка с минимальным воздействием на окружающую среду-идеально подходит для различных компонентов

Ультразвуковой очиститель с системой масляного фильтра

Ультразвуковой очиститель BIOBASE для лаборатории

Новые поступления

Новинки товаров от производителей по оптовым ценам