Дробеструйная машина для очистки подложки дисковых тормозных колодок производственная линия

- Категория: >>>

- Поставщик: Shandong Kaitai Shot Blasting Machinery Share Co. Ltd.

Сохранить в закладки 1600413684009:

Описание и отзывы

Характеристики

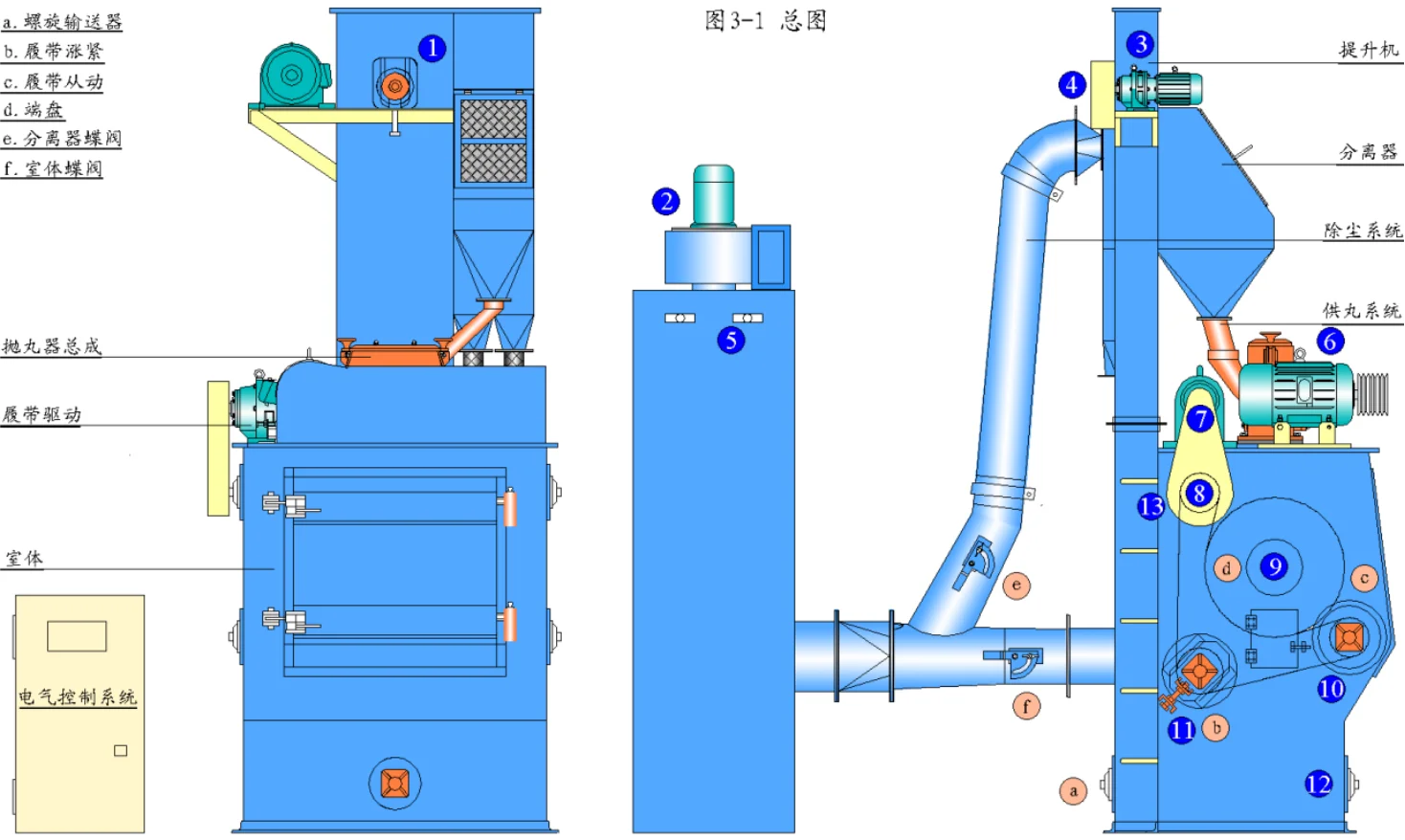

Tracked shot blast clean-up machine has advantages of advanced design,rational construction,low-power.

Q32 tumble shot blasting machine offers reasonable structure, low energy consumption and high efficiency. The blast

chamber is equipped with wear protection plate on the inner wall to avoid punctures due to shots at a high velocity. The

rubber belt conveyor allows easy tumbling of workpieces and has many shot leakage holes for the cycle of balls.

Parameter | Unit | Q326 | Q3210 | QR3210 |

Productivity | T/H | 0.6-1.2 | 3-5 | 1.5-2.5 |

Loading Weight | KG | 200 | 600 | 600 |

Maximum Weight of One Piece | KG | 10 | 15 | 30 |

Diameter of the Roller | mm | 650 | 1000 | 1000 |

Available Capacity | m³ | 0.15 | 0.3 | 0.3 |

Power Air Volume | m³/h | 2200 | 6000 | 5000 |

Outline Dimensions | mm | 3681*1650*5800 | 3644*2926*5856 | 3972*2600*4768 |

Machine Total Weight | KG | 2340 | 5843 | 7400 |

Shandong Kaitai Shot Blasting Machinery Share Co.,Ltd is affiliated to Shandong Kaitai Group Co.,Ltd.It is focused on metal surface treatment industry and devotes to the manufacturing of shot blasting,sand peening equipment and the related spare parts,The company adopts advanced shot peening and sandblasting technology introduce from Airblast in the Netherlands.It is the professional large scale production base of domestic shot blasting/peening and sand blasting/peening equipment.

Coopering with Jinan University,the company is indicated in R&D of surface shot blasting,shot peening,strengthening and other equipment,set up first class R&D centre and perfect quality control system,and pass through ISO9001 international quality system certification.

1.Product feature

A.Advanced investment casting process and technology;

B.High efficincy and automatic single station drying production line;

C.The special high chromium abrasion casting iron shot blasting machine spare parts,making up gaps in the domestic industry.

2.Production application

It is used for machinery,mining,construction machinery,engineering machinery fields,we also could produce casting according to customer’s drawing and samples.

1.Product introduction

The main part of the impeller efficient shot blasting machine is made of high quality low carbon alloy material with a special heat treatment process backward action balance detection ;

Control cage,distributor,blade,guard plate,the bo ards are made of special wear resistant material made by ourselves,has high wear resistance and service life of bearing;

Blasting whee shell adopt robot welding,spindle is made of high quality carbon steel,imported machining center,high machining precision;

Selecting of bearing manufacturers domestic Nameplate Factor orders,accuracy is higher than the national standard 1-2 grades.

Because the impeller machining process of shot blasting device by dynamic balance test and leaves the weighting test group,so as to ensure the reduction of vibration shot blasting machine working process,reduce the noise of the whole equipment,cleaning equipment environment.

2.Product feature

A.Improving shot blasting speed

B.Good wear resistance

C.Greatly reducing energy consumption

D.Extraordinary service life

E.Suitable structure form

Our company has nationwide sales network.There are seventeen sales branch company and 55 offices.There are ten warehouse throughout the country.Now the customer has exceed more than 8000.

We have started comprehensive cooperation with AIRBLAST company in 2012.Now we have the following branch company in the world :

Netherland, Qatar, Saudi Arabia,Dubai,Brazil,India,Malaysia,Singapore,Shanghai .The Foreign employees have exceed more than 200.We will establish First 4S shop in global shot blasting (peening ) industry.

A : Yes, we have perfect after-sale service

• Q : How long can your spare parts be used?

A: Blade, control cage and distributor are high chrome, and can be used for more than 2000 hours.

Kinds of guard board can be used for more than 3000 hours.

• Q : How about your company ?

A: Our company is the biggest manufacturer of metal abrasive and shot blasting machine in china , we have exported to more than 60 counries and regions , and got good comments from overseas and domestic.

• Q: What standards are you carrying out for your products?

A: We produce according to the ISO9001 and ISO14001 rules.

• Q: How to install the machine?

A: We will arrange 1~2 engineers to your factory to guide installation and assembly.

• Q: What’s your international market?

A: We Have exported to about 60 countries and regions all around the world, such as, the USA, France, Singapore, Australia,

Middle East, Brazil, Peru and so on.

• Q: Do you have the right to export?

A: Yes, we registered in the Customs and gained the right to export by ourselves.

welcome to contact with us in any time ! We will fully committed to provide the best quality products and services.

Похожие товары

Заводская поставка, 3/8 дюйма, высокое давление, синий цвет, воздушный тормозной шланг, воздушный компрессор, катушечный шланг

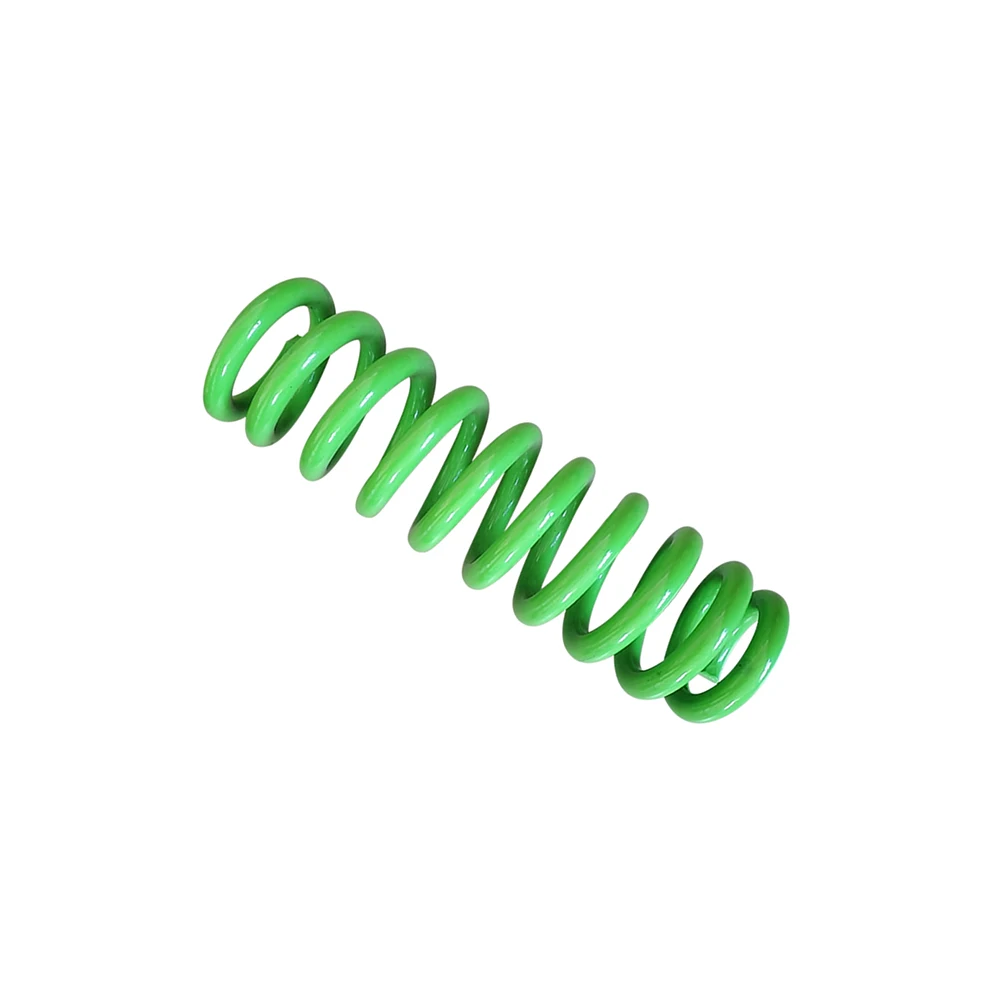

Оптовая продажа, китайский поставщик, хорошее качество, производитель, Высококачественная локомотивная амортизационная пружина

Профессиональная гусеничная дробеструйная машина, используемая для литейной фабрики, производство тормозных колодок, дробеструйная машина

Самые продаваемые товары на alibaba, производители медных тормозных труб со стальными катушками

Пружинный компрессор 3 тонны 6600 фунтов, автоматический гидравлический инструмент, новый

Производитель одиночный AA положительная и отрицательная контактная батарея Весна

Лучшие цены лезвия доктора в катушках для печатной техники

Новые поступления

Новинки товаров от производителей по оптовым ценам