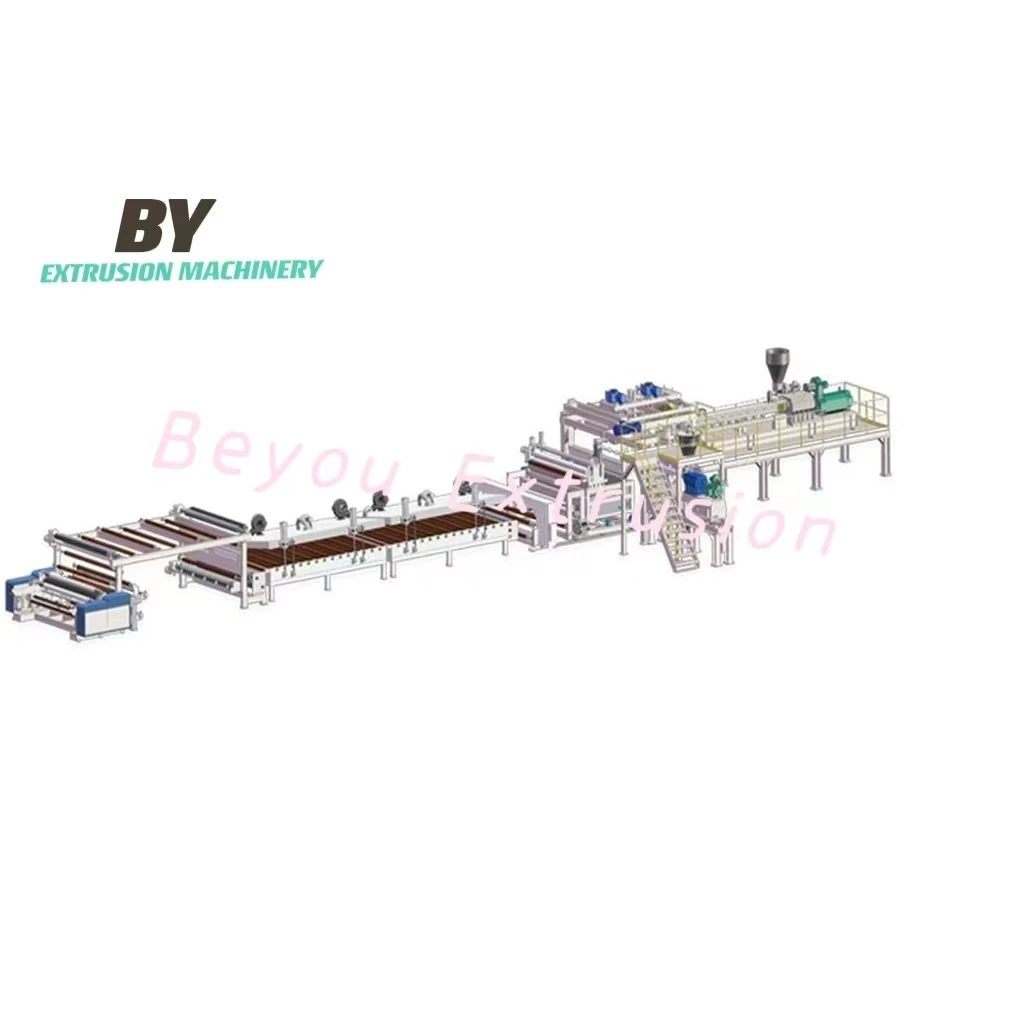

Производственная линия PVB SGP EVA POE для экструзии пленки

- Категория: >>>

- Поставщик: Nanjing Beyou Extrusion Machinery Co. Ltd.

Сохранить в закладки 1600423879073:

Описание и отзывы

Характеристики

PVB Intermediate Film Production Line Characteristics:

1.The Optimally designed twin screw extruder can produce PVB resin powder and PVB film recycling in any ratio.

2.Fully automated material handling system, highly automated raw material proportioning system.

3.Roll forming, Water forming, Membrane embossing molding, three forming methods to meet the needs of different customers.

4.Automatic winding device.

5.Turn-key project.

Type | Do/DI | Max.Products Width | Products Thickness | Output | Max.Line Speed | |||||

CTS75/CTS35 | 1.71 | 2750mm | 0.38-1.52mm | 200-300kg/h | 25m/min | |||||

CTS95/CTS52 | 1.54 | 3000mm | 0.38-1.52mm | 400-700kg/h | 25m/min | |||||

CTS120/CTS65 | 3600mm | 0.38-1.52mm | 600-900kg/h | 25m/min | ||||||

CTS135/CTS75 | 4000mm | 0.38-1.52mm | 800-1400kg/h | 25m/min | ||||||

That inserted layer of PVB is what allows the glass to absorb energy during an impact and gives the glass resistance to penetration from flying projectiles. It also deflects up to 95 percent of ultraviolet (UV) rays from the sun [source: Reuters]. Laminated glass can break and be punctured, but it will stay intact because of its chemical bond with the PVB.

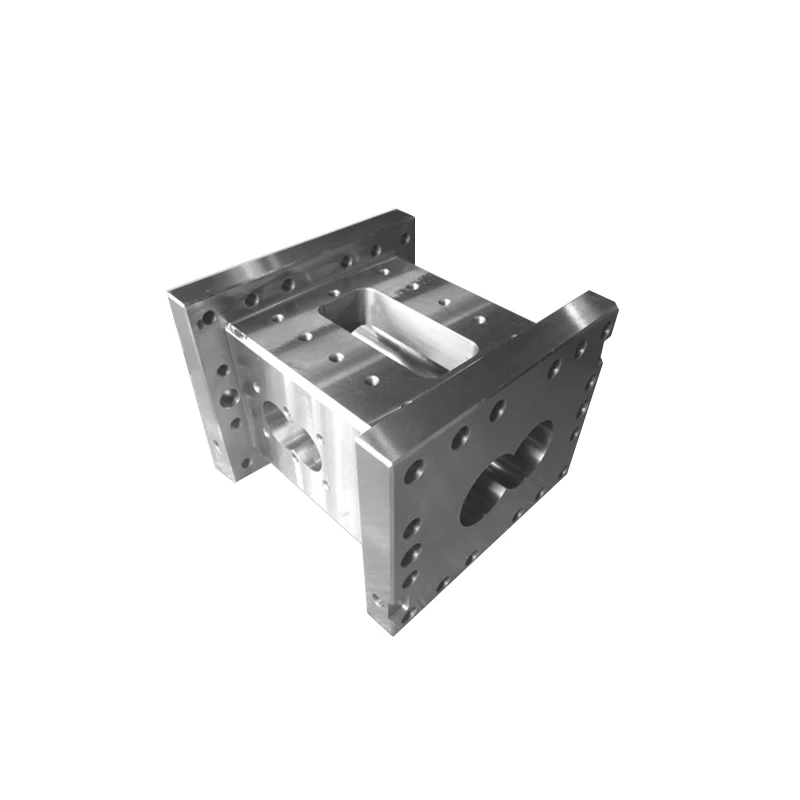

Depending on the nature of work being carried out, there are Intake zone, Conveying Zone, Melting Zone, Natural Venting Zone, Mixing Zone, Vacuum Venting Zone and Metering Zone.

Different screw elements own different features in different extrusion process, we should choose and design the right screw elements based on different extrusion status in order to optimize the overall comprehensive performance in the extrusion process.

According to appearance design, it can be divided into close barrel, open barrel and venting barrel.

According to the liner, it can be divided into integrated barrel (without liner) and with liner barrel.

Diameter: 12-350mm

Material: Company adopts imported HIP process of powder high speed steel, and precision CNC machining of the cylinder is adopted to make its accuracy level, wear-resisting and corrosion resistance be consistent with the origin first-line brand abroad; Cost performance is superior to the similar imported products.

Workshop

Warehouse

Team

About us:

Nanjing Beyou Extrusion Machinery Co.,Ltd. is a professional rubber and plastic machinery manufacturer, mainly engaged in plastic extrusion machine as the core of the plastic modification equipment and related technology and engineering field of research and development and production of auxiliary machines. The main products are twin-screw extruder, single-screw extruder, PVB intermediate film production line equipment, glass fiber reinforced thermoplastics production line and self-developed underwater granulation system, which are widely used in various kinds of plastic and rubber materials, such as coloring, blending, filling, strengthening, stripping and recycling. According to different requirements of customers, we can provide appropriate solutions for customers.

Our company leads the industry in either software or hardware. Now it has a high-quality R&D team and engineering team that have engaged in the field of twin-screw extruder for many years. We have equipped with standard workshops, various automated advanced processing equipment and modern quality testing center. Our company invests huge sums of money in R&D every year to cooperates customer's development requirements, and dedicated to provide customers with technical design, machine assembly and on-site debugging services, strive to create greater economic and social benefits for customers.

Packing Details: Wood cases or sea worthy packing.

Delivery Details: Within 8 weeks from the receipt of your down payment.

After-Sales Service:

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

A: We are factory.

A: Yes.Before making your decision buying the equipment or not, you can bringsome material here to test-run the equipment.

A: Please fill in your specific requirement in the bottom blank and sent to us, so that we could make a detail quotation for you.

A: (1)You can get to the lukou airport directly, then, connecting us and we will pick you up by car.

(2)You can take the train to nanjing south station, then, taking the subway to get to China Pharmaceutical University Station, we will pick you up by car.

If you have another question, pls feel free to contact us as below:

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Похожие товары

Многофункциональный портативный деревообрабатывающий рубанок Электрический рубанок наковальня для обработки древесины

Клапан EGR 17200272 851038 5821024 17098055 для Opel Zafira A 99-05

2022 новый дизайн надувная полиуретановая лодка из ПВХ для

Плавательный бассейн тест-набор для измерения температуры воды с подсветкой 4 в 1 измерительный прибор TDS/EC солености/температура воды качество тормозной стенд для гидропоники

Креативные ноты в скандинавском стиле, Декорации для пианино, для персонала, музыкальные ноты, подарки, Декорации для пианино, украшение для Кабинета

Для монтажа в панель сильфонные мбар датчик низкого

M-9061G ванной по оптовой цене китайский Туалетная чаша для серый цвет Золотая линия сантехника писсуар керамический цельный туалет

Новые поступления

Новинки товаров от производителей по оптовым ценам