Порошковая Металлургия спеченный маленький дифференциал 14 мм планетарный редуктор для деталей

- Категория: >>>

- Поставщик: Dongguan Yongxin Hardware Mould Products Co. Ltd.

Сохранить в закладки 1600426698722:

Описание и отзывы

Характеристики

Product Overview

Miniature planetary gears set

We are manufacturer and exporter of sintered metal parts with 9 years experience, mainly produce small spur gears,bevel gears,helical gears,pinion gear wheel,metal bushing, miniature planetary gear set and other sintered structural metal components,any metal parts can be customized.according to your drawing.

Powder metallurgy(PM) is a state of the art metal-forming process used to produce net-shape components,which typically uses more than 97% of the starting raw material in the finished part. It is basically a “chipless”metalworking process

FEATURES AT A GLANCE

Advantage of planetary gear systems

The more the planets in the system, the greater the load ability, and the higher the torque density

Speed ReductionObtain high power density

Large reduction in small volume

Pure torsional reactions, and multiple shafting

Creates greater stability

The more the planets in the system, the greater the load ability, and the higher the torque density

Sintered Planet gear

Sintered planetary metal parts

Sintered sun gear

PRODUCT SPECIFICATIONS

Technology | Powder metallurgy |

Material | Stainless steel,mild steel,Iron,Brass,Copper,Aluminum,Soft Magnetic Alloy, Customized blends |

Gear stage | Customized |

Density | 6.5~7.6 according to material and your required |

Tolerance | ±0.01mm or as your request |

Size | According to your drawing(stp,dwg,igs,pdf),or sample,provide custom service |

Sample | Available |

Application | Medical apparatus and instruments Power tool Automobile industry Home appliances etc... |

Small Planetary Gears Set, size and shape is customized

Small planetary gears system with 37mm outer diameter of sintered ring gear

Small planetary gears system with 59.6mm outer diameter of sintered ring gear,1 mould gear

Planetary gearbox set is used for various motors, applying in power tool motor, screwdriver motor, home appliances motor,Garden Tools motor,industrial machinery motor

Benefits of Using PM in Gear Manufacturing

* Ability to produce high precision components in volume.

* Only the exact amount of material is used.

* Net shape production eliminates or minimises machining.

* GTB’s patented process can completely eliminate secondary

machining for cross holes in certain applications leading to further

material & machining savings.

* Density, or conversely porosity, can be accurately controlled to suit

particular requirements.

* Allows combination of materials which cannot be produced in any

other way, including dissimilar metals, non metallic and materials with

widely differing characteristics.

* Allows design in of self-lubricating properties.

* Only the exact amount of material is used.

* Net shape production eliminates or minimises machining.

* GTB’s patented process can completely eliminate secondary

machining for cross holes in certain applications leading to further

material & machining savings.

* Density, or conversely porosity, can be accurately controlled to suit

particular requirements.

* Allows combination of materials which cannot be produced in any

other way, including dissimilar metals, non metallic and materials with

widely differing characteristics.

* Allows design in of self-lubricating properties.

The metal gear and Production Process can be customized. More details or custom please feel free to contact us.

Item | PM | Precision casting | Machining operation | Stamping |

Range of Applying material | High | Medium-high | Medium | Medium |

Design Tolerance | High | High | High | Low |

Small Size | High | Low | High | High |

Thickness | High | High | Low | High |

Supply Ability | High | Medium | Low | High |

Raw material ultilization | High | Low | Low | Low |

Property | PM | Precision Casting Molding |

Surface Roughness | Ra1.6 | Ra1.6 |

Minimum Thickness | 0.8mm | 2mm |

Maximum Thickness | 60mm | Unlimited |

Minimum Diameter | 0.5mm | 2mm |

Tolerance of Diameter | +/_0.01mm | +/_0.2mm |

Company Profile

Dongguan Yongxin hardware company

We are professional manufacturer of all kinds of metal parts with 9years experience, specialized in powder metallurgy and CNC machining.We can offer the plans for your choice to achieve the best price and quality with different production process.

Now turnover of our export sales rises by 30% steadily each year

Our Equipment

Dongguang Yongxin Hardware own 6000 square meters and more than 150 sets of high precision equipment for Powder metallurgy device, Sintering furnace, CNC machining equipment,Slow speed Wire Cut,Measurement Instrument,Surface treatment etc.

At the same time,we have more than 150 professional technicians and service team to guarantee on-time delivery and qualified products.A professional QC team with complete QC equipment ensures that products are qualified from raw material to final products.

Inspection workshop

1.We have specialized QC testers to check the products quality according to different customers.

2.We have IQC to check the incoming material.

3.We have PQC to inspect full-course during the processing

4.We have FQC to inspect all the final products and make the 100% inspection before the shipments.

2.We have IQC to check the incoming material.

3.We have PQC to inspect full-course during the processing

4.We have FQC to inspect all the final products and make the 100% inspection before the shipments.

FAQ

Q1:What's powder metallurgy processing?

● Powder metallurgy or PM-is a state of the art metal forming process used to produce net-shape components.

● Made by mixing elemental or alloy powders and compacting the mixture in a die, the resultant shapes are then

sintered (heated) in a controlled-atmosphere furnace to bond the particles metallurgically.

● PM typically uses more than 97% of the starting raw material in the finished part,which is basically a “chipless”

metalworking process

● Made by mixing elemental or alloy powders and compacting the mixture in a die, the resultant shapes are then

sintered (heated) in a controlled-atmosphere furnace to bond the particles metallurgically.

● PM typically uses more than 97% of the starting raw material in the finished part,which is basically a “chipless”

metalworking process

Q2:Do you make customized products based on our design/drawings?

Yes (PDF/STEP/IGS/DWG...)

Q3:Will my drawing be safe after you get it?

Yes, we can sign the NDF before you send the drawing.

Q4:Do you provide some samples?

Yes,sample fee is needed, it will be returned when mass production if possible.

Q5:How to deal with the parts received when they are found to be in poor quality?

Our engineers will find the solutions and remake them for you asap.

Q6:Can we know the production process without visiting factory?

We will offer detailed production schedule and send weekly reports with digital pictures and videos of the production process.

Q7:Do you test all your products before delivery?

Yes. If quantity is large, then a sample batch of 5-10% of the quantity.

Yes. If quantity is large, then a sample batch of 5-10% of the quantity.

Похожие товары

Подарочный набор для ванны и спа, Рождественская подарочная корзина, набор из 5 предметов корзины для спа с ароматом лаванды, включая гель для ванны, пузырчатую ванну, тело

2,50 $

Закрытый пищевой 3 направляющими типа ноги твердый настил hdpe евро пластикатов поддон из 4 способа пластиковый Евро салазки вентилируемый

30,00 $ - 49,00 $

2 дюймов Ips полный угол обзора ЖК-дисплей на основе тонкоплёночной технологии 240*320 пикселей цветной ЖК-экран

6,00 $ - 10,00 $

Бытовая безопасная портативная бутылка для промывки глаз

Блок питания 380 - 430 в, грузоподъемность 2 тонны, производитель козлового крана

45 000,00 $

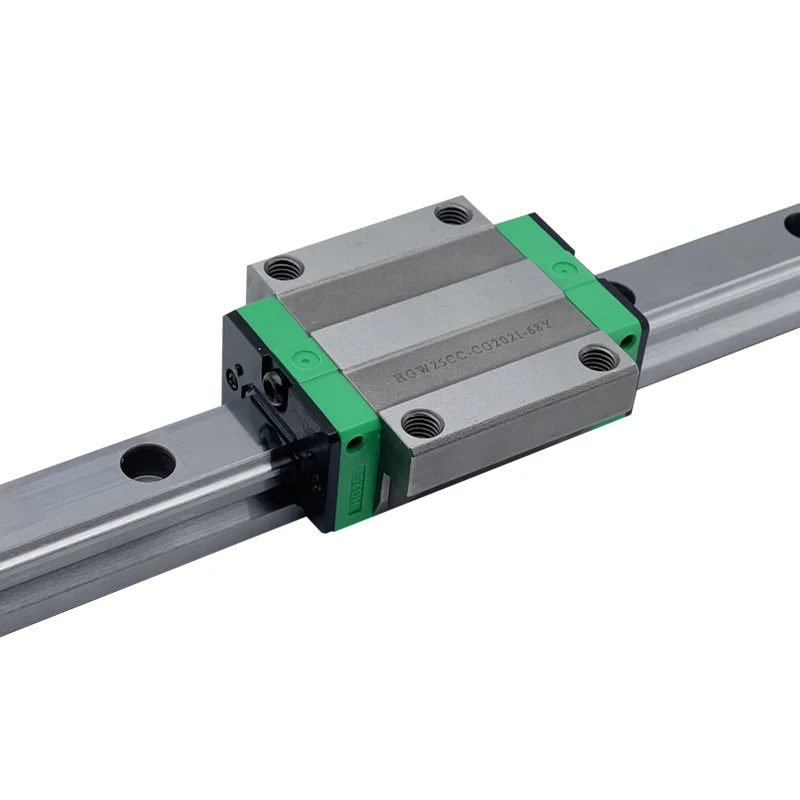

Поставка из Китая, Высокоточный Линейный направляющий рельс и блок

Anarkali Дизайнерская одежда для вечеринки новый образ шелковая вышитая каменная работа индийская Женская производство полной длины патияла

16,00 $ - 20,00 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $