Картонный фильтр пресс для фильтрации крови с технологией высокого уровня разделения inc

- Категория: >>>

- Поставщик: Zhengzhou Toper Industrial Equipment Co. Ltd.Zhengzhou Ltd.

Сохранить в закладки 1600427117954:

Описание и отзывы

Характеристики

Cardboard filter press for blood filtration

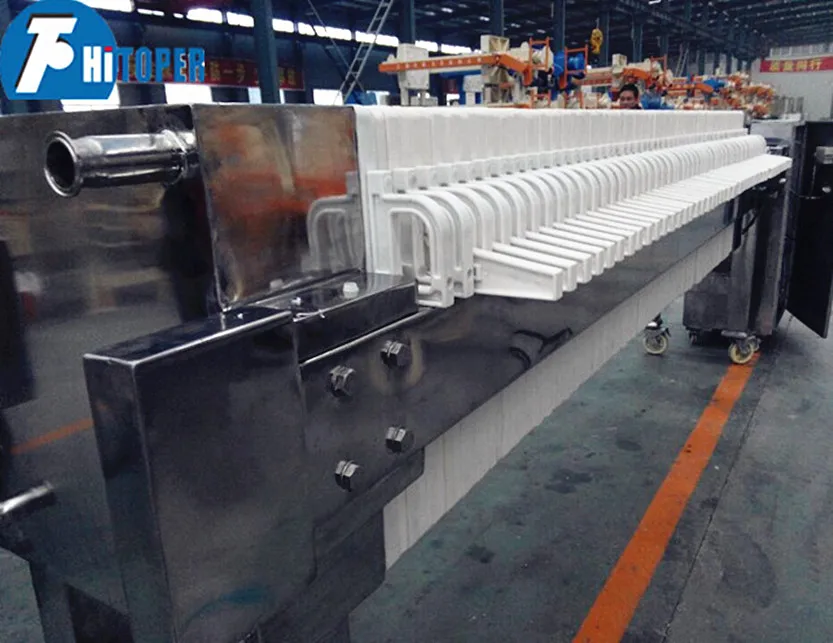

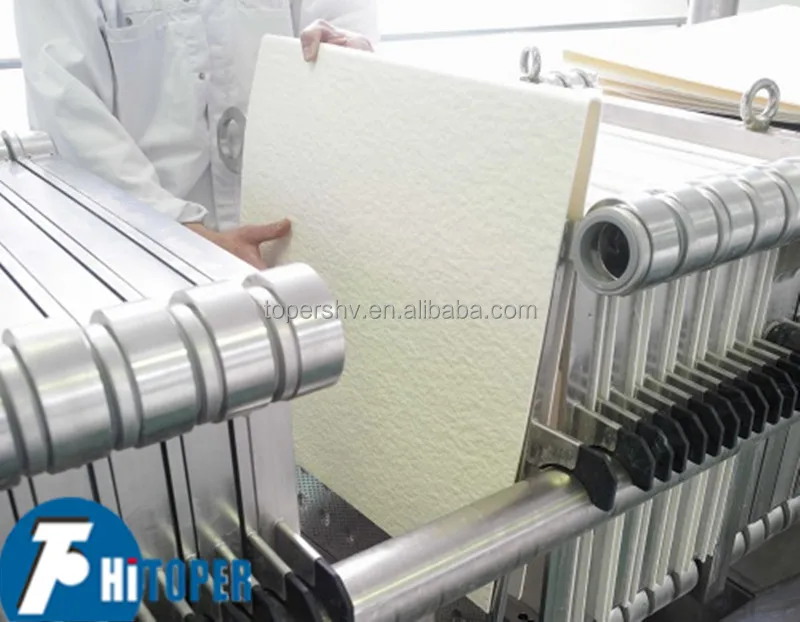

Cardboard filter press is an intermittent, plate and frame type filter equipment used for liquid/solid separation of various suspending liquid. It is a high-precision filtration equipment using cardboard as the filter medium. The machine frame is made of high quality carbon steel, and can be coated with stainless steel as requested. The filter plates are make of reinforced polypropylene(PP), which is acid & alkali resistant, anti-corrosion, innocuous, odorless, light weight and high-strength. The quantity of frame can be increased or reduced.

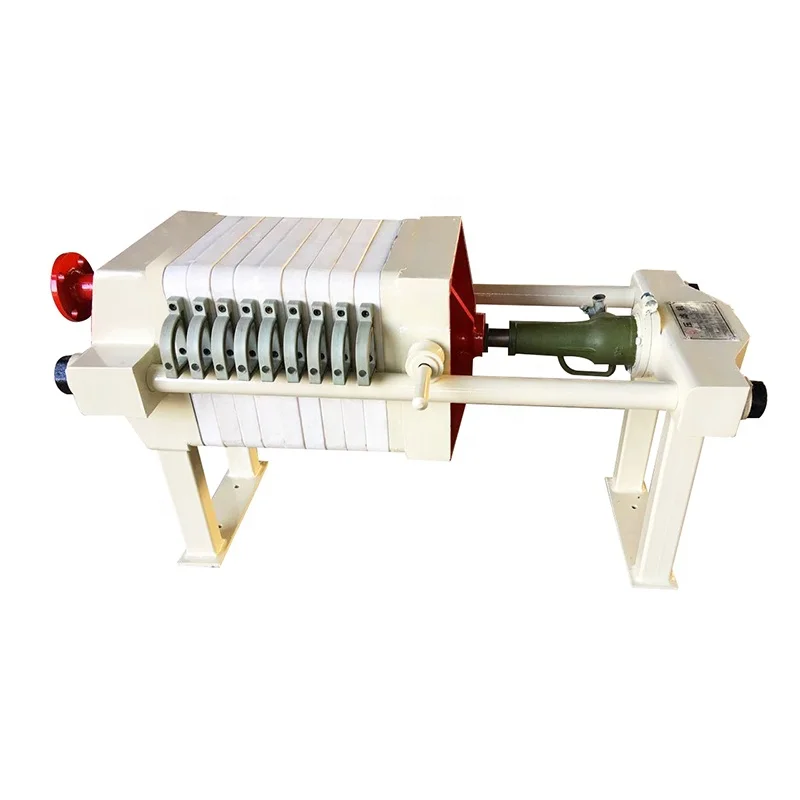

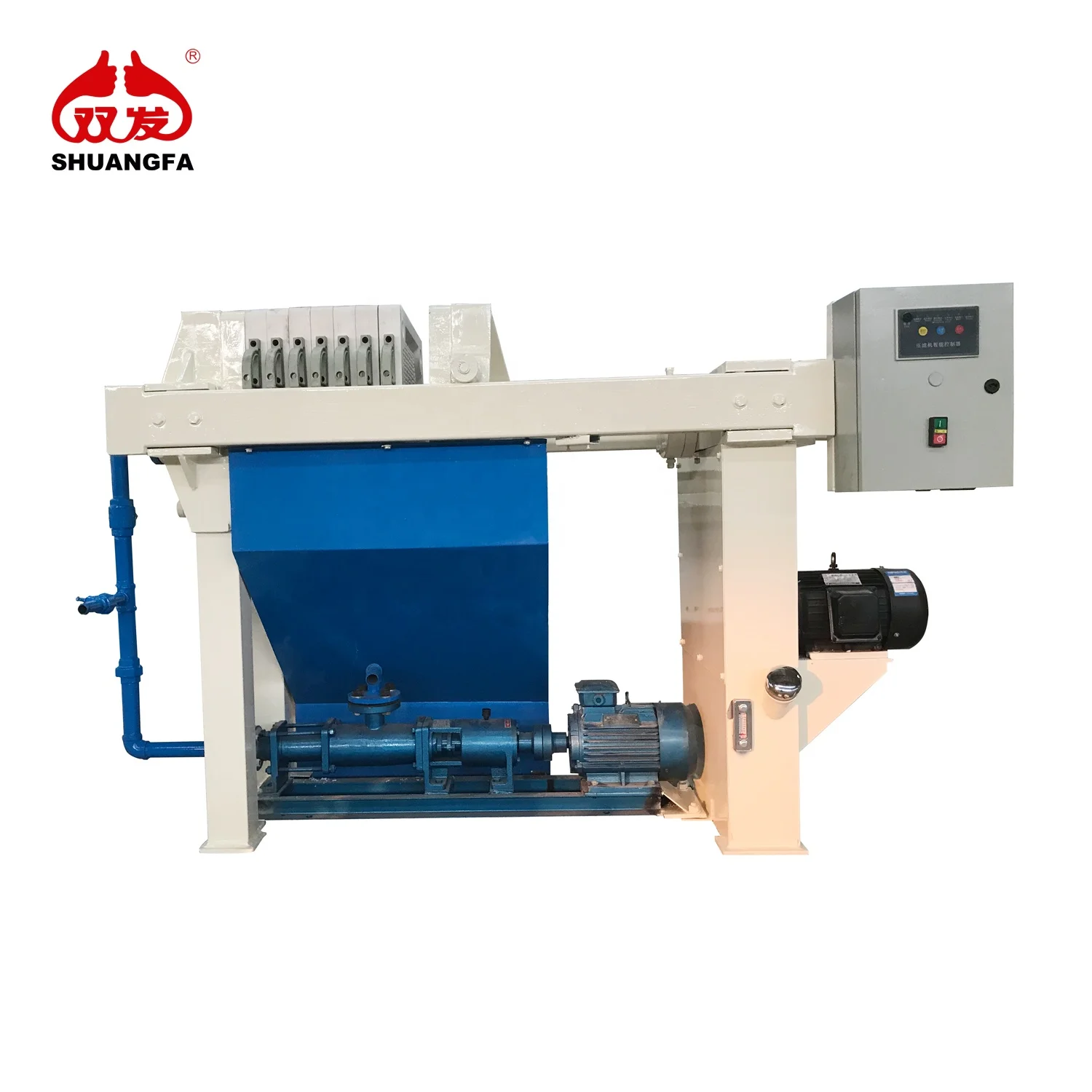

Cardboard filter press consists of frame, filter plate, pressing system (manual, mechanical or hydraulic) and electric control cabinet. Frame consists of base, push plate, tail plate and beam. The frame supports the pressing device and filter plates. Filter plates are installed on the beam between push plate and tail plate, with filter cloth sandwiched in them.

Cardboard filter press consists of frame, filter plate, pressing system (manual, mechanical or hydraulic) and electric control cabinet. Frame consists of base, push plate, tail plate and beam. The frame supports the pressing device and filter plates. Filter plates are installed on the beam between push plate and tail plate, with filter cloth sandwiched in them.

In operation, the pressing device (cylinder piston rod or screw) drives the push plate to press the filter plate and filter cloth between push plate and tail plate. Filter chamber are formed between pressed filter plates and materials get into the filter chambers through the feeding inlet of tail plate. Solid particles are remained in filter chambers forming into cakes, while liquid is discharged out of the machine through press cake and filter cloth. The dewatered filter cakes are quickly discharged by gravity as the press opens, and the procedure is repeated.

Low production costs.

Least impact on the environment. It is 100% recyclable and biodegradable.

Can carry greater work pressure with small pressure loss and low operating cost.

Trolley cart.

We offer convenient self-dumping cake carts for easy disposal of your slurry cakes. The low-profile design of the cake cart allows for convenient loading. The cake cart is placed directly below your filter press so that cakes fall directly into the cart. When full, simply pull the cake cart out with the handle and easily dump the contents into a dumpster or other secure container.

Solid-liquid separation in industries such as:

Mining.

Metallurgy.

Petroleum.

Chemical.

Medicine.

Textile.

Printing and dyeing.

Paper making.

Food and beverage processing.

Inorganic salt.

Coal washing.

Ceramics.

Leather.

Biological.

Sewage treatment industries.

Environmental protection unit, etc.

Cardboard filter press is for applications where product clarity is a major concern - including pharmaceutical, beverage, cooking oil, wine, whiskey, and syrups. For example, when the machine is used for filtration of blood products, it is also known as plasma separation machine. Therapeutic plasma exchange (TPE) or plasmapheresis involves the separation of plasma from whole blood. During plasmapheresis, blood (which consists of blood cells and a clear liquid called plasma) is initially taken out of the body through a needle. Plasma is then removed from the blood by a cardboard filter press. In so doing, plasma-borne humoral disease mediators are removed from the body. This can attenuate the course and severity of the underlying disease.

Company

Zhengzhou Toper is the leading suppiler of industrial equipment in China, and also the professional exporter and service provider of filter and separation equipment. We focus on full service for filtering project from design to after-sales service and fast supply of spare parts.

Since 2006, Zhengzhou Toper has supplied products and services to over 200 enterprises of more than 30 countries all around the world:

Southeast Asia: Indonesia, Malaysia, Philippines, Thailand

West Asia: Turkey, Uzbekistan, Tajikistan

Northeast Asia: South Korea, Mongolia

Middle East: Israeli, Palestinian, Oman, Bahrain

Europe: Russia, Italy, Spain, Ukraine, Finland, Poland, Romania

North America: United States, Canada

South America: Mexico, Guatemala, Argentina, Brazil, Chile, Peru, Bolivia

Africa: South Afarica, Algeria

All products of Toper:

1. Program-controlled automatic filter press

2. Membrane filter press

3. Hydraulic compress filter press

4. Mechanical compress filter press

5. Jack filter press

6. Cast iron plate and frame/chamber filter press

7. Stainless steel plate and frame filter press

8. Round plate filter press

9. Cotton cake filter press

10. Cardboard filter press

11. DY belt filter press

12. DYX high pressure belt filter press

13. DNY rotary drum thickening/dehydrating belt filter press

14. Triple-belt thickening and dehydrating filter press

15. SS type three-foot upper discharge centrifuge

16. SD type three-foot and filter bag hoist discharge centrifuge

17. PD type filter bag hoist discharge centrifuge

18. Centrifuge of up discharge, three foot, clean series SSB, SB

19. SX type manual top discharge centrifuge

20. PS type manual top discharge centrifuge

21. SGZ type automatic scraper bottom discharge centrifuge

22. PGZ type scraper bottom discharge centrifuge

23. LW series decanter centrifuge

24. Tubular centrifuge

25. Multi-layer stainless steel frame filter

26. Bag filter

27. Diatomite filter

28. Filter plate

29. Filter cloth

30. Vacuum disc filter

Order notice

1 All of our products are provided without a pump and pipes. To order a complete unit, please state it in the contract.

2 Products can be customized by changing colors and materials, altering the size, or adding logos, to meet your special demands. We use materials and components from market leaders and well-known manufacturers.

3 It can be designed and manufactured as per GMP specifications.

Contact us

Похожие товары

Низкая цена ручной фильтр-пресс

Пластинчатый каркасный фильтр из нержавеющей стали для пищевого масла соевого соуса жидкий очистки остатков фильтр-пресс

Чистый ленточный барабан загуститель и Дегидратор (нержавеющая сталь углеродистая сталь)

Полипропиленовый фильтр-пресс для сиропа машина фильтрации пива вина тарелок и рамок

Ручной пресс-фильтр небольшого размера подвижная пластина из полипропилена Лучшая цена быстрая доставка

Верхний фильтр-пресс с широким полем зрения/Низкая частота отказов гидравлический

Фильтровальная ткань для пищевых применений сахарной промышленности

Новые поступления

Новинки товаров от производителей по оптовым ценам