SPR альтернатива точечной сварке самопрокалывающая плоская головка полутрубчатая заклепка вставлена в металлическую плоскую головку HRC42 и 47 Dacromet

- Категория: >>>

- Поставщик: Suzhou Blueter Hardware Products Co. Ltd.Suzhou Ltd.

Сохранить в закладки 1600430656672:

Описание и отзывы

Характеристики

Product Category

Product Description

Self-piercing riveting (SPR) is a way of joining sheet materials using a rivet that clinches the sheets as it is pressed into them. Unlike conventional riveting, no hole is required, making it a rapid single-step process.

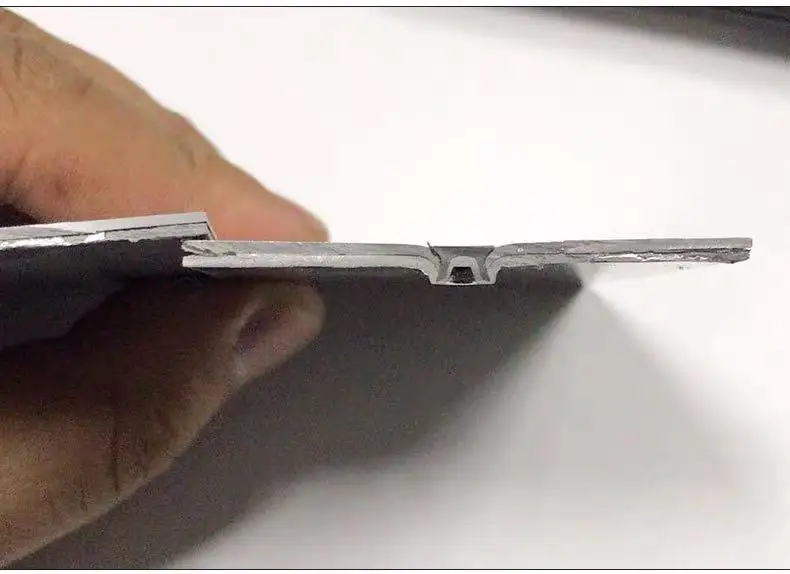

Typically, the first sheet is pierced when the rivet is inserted. Then, the second sheet is deformed into a button as the rivet is caught within it. The process is similar to clinch joining, however, in clinch joining no rivet is used and a punch deforms the sheets into an interlocking button.

With SPR, the sheets are deformed by a rivet that remains in place and forms the interlock between the sheets. However, SPR requires access to both sides of the joint.

The sheets are first clamped between a die and a blankholder. The rivet is then driven through the sheets using a press tool, piercing the top sheet and causing the lower sheet to expand into the die. The shape of the die causes the rivet and the lower sheet to flare outwards, forming a mechanical interlock.

The rivet head may be finished flush with the top sheet but the bottom sheet will always protrude in a button, which is typically not pierced.

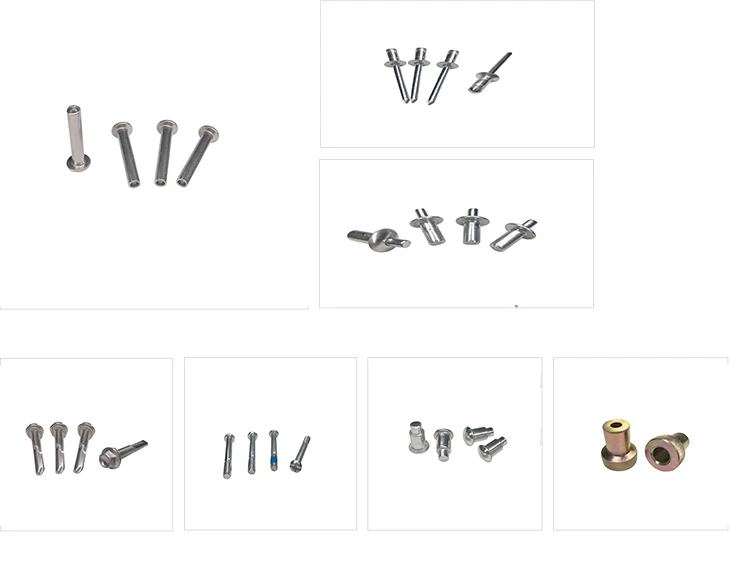

There are several proprietary processes for self-piercing riveting, typically using a semi-tubular rivet, although solid rivets are also sometimes used.

Unlike welding, self-piercing rivets can be used to join dissimilar metals or non-weldable materials.This is becoming increasingly important in the automotive industry where a mixture of aluminum and steel panels are being used. Self-piercing rivets are, therefore, being used instead of spot welding in some vehicle designs.

SPR is an effective way of joining parts made from any combination of aluminum, steel, plastic or composite.

Other advantages include a lack of fumes and sparks, no heating of materials, low noise, and low energy consumption. It’s also suitable for use on pre-coated materials that are unsuitable for welding. Blind rivets, for example, are used for car body assembly where access constraints mean that the joint can only be accessed from a single side. In this case, SPR has zero advantage because access from both sides is required to upset the rivet.

| Material for optional | carbon steel |

| Head type | flat head |

| Surface treatment | Electrophoresis, Cleaning and polishing |

| Certificate | |

| Application | furniture Satellite Baby carriages Car seats Hospital beds etc |

| Sample | free of charge |

| OEM | Yes |

| Standard | DIN |

| Product Keywords | High Strength flat head semi tubular rivet 5.3mm SPR Rivet Carbon Steel Dacromet Plated Self Piercing Rivet for Auto Body Repair flat head |

Related Products

Company Information

Certifications

Our Advantages

FAQ

Packaging & Shipping

PACKAGE:

Standard export carton packing with pallet.

DELIVERY TIME:

7-15 days after confirming order,detail delivery date should be decided according to

production season and order quantity.

Похожие товары

ST/ST HEMLOCK заклепка для шлепки жесткий замок REMACHE 4 8-6 мм

0,01-0,04 $

Нержавеющая сталь высокой прочности кирпечей из глины слепых заклепок Pop Rivets

0,01-0,04 $

6 мм двойная крышка металлические заклепки Шпильки для кожи

0,01-0,05 $

7 5x28 мм структурная алюминиевая трехскладная лампа типа фонаря трехскладные водонепроницаемые заклепки с шайбой EPDM

0,11-0,55 $

Прямая поставка с завода в Китае стальные Твердые заклепки

0,01-0,05 $

Высокое качество сделано в Тайване компоненты замка индивидуальные заклепки из нержавеющей стали с плоской головкой

0,10-0,20 $

M3 M5 M6 M8 M10 потайная Шестигранная плоская рифленая гладкая Заклепка гайка

2,22-5,55 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

Hantek щупы осциллографа автоматический Тестовый Кабель Ht30a Bnc к банану двойная Банановая головка многоцелевое автомобильное

3,10-3,44 $

Горячая распродажа ручная работа традиционная деревянная урна для домашних животных квадратная коробка золы собак и кошек персонализированная Лучшая цена

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $

Irdmco экологически чистый минималистичный прямоугольный деревянный ящик для хранения стеллаж поделок и детских игрушек Домашняя мебель гостиной

Технология сенсорных перчаток и аксессуары для детей от дождя холода M725132-334

1,07-1,40 $

GY6 6 Pin AC гоночный CDI для CG125 CG250 двигателя Dirt Pit Bike ATV Quad

Парик из синтетического волокна для косплея

9,85-12,66 $

Прямая Продажа с фабрики 65 см Модернизированный подвесный стерео голографический проектор светодиодный вентилятор высокой четкости экран 3D дисплей

155-185 $