Концевые заглушки для стальных труб 40X40 квадратные пластиковые концевые фитинги круглые прямоугольные

- Категория: >>>

- Поставщик: Shenzhen Longhua Covision Mechanical & Electronics Firm

Сохранить в закладки 1600438078719:

Описание и отзывы

Характеристики

Our Services

General: we own the latest in injection compression, transfer, extrusion and dip molding technologies, we keep our end cap products the same pace with the market trend and the Customer's innovation. Completing with an in-house tooling and mold making shop allows us to offer very low tooling costs and competitive piece prices.

Our professional and Customer-oriented sales team are ready to provide you tailored solution with thousands types of products both on-line and off-line.

Features

• Durable and Inexpensive

• Tapered Design Fits Multiple Diameters

• Dual Function Closure Can Be Used as a Cap or Plug

• Installs without tools

Applications include

• Thread protectors

• Product finishing

• Masking

• Protects Against Debris, Damage, Moisture and Corrosion

Details

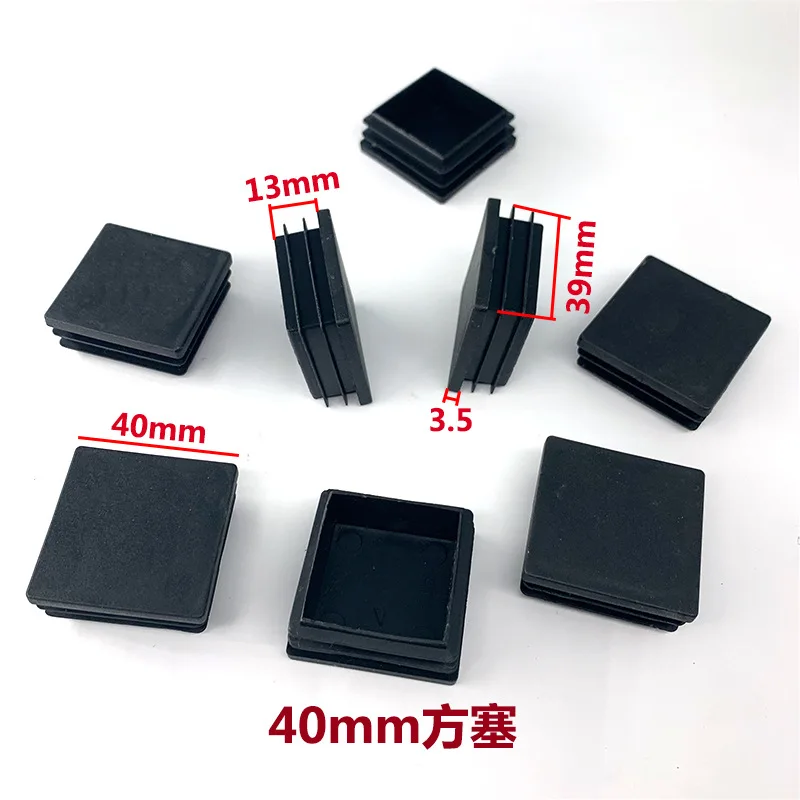

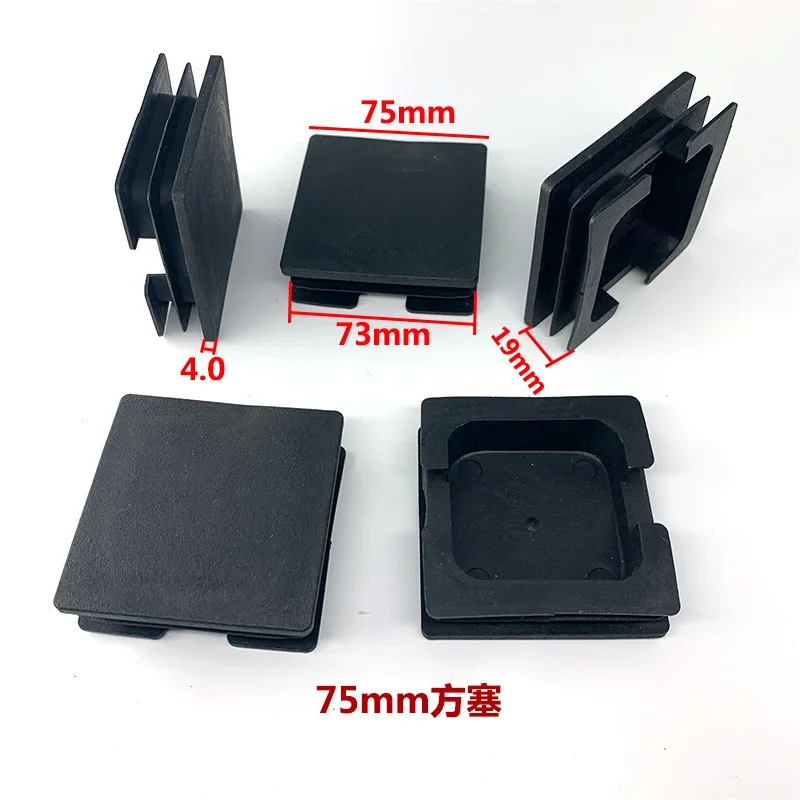

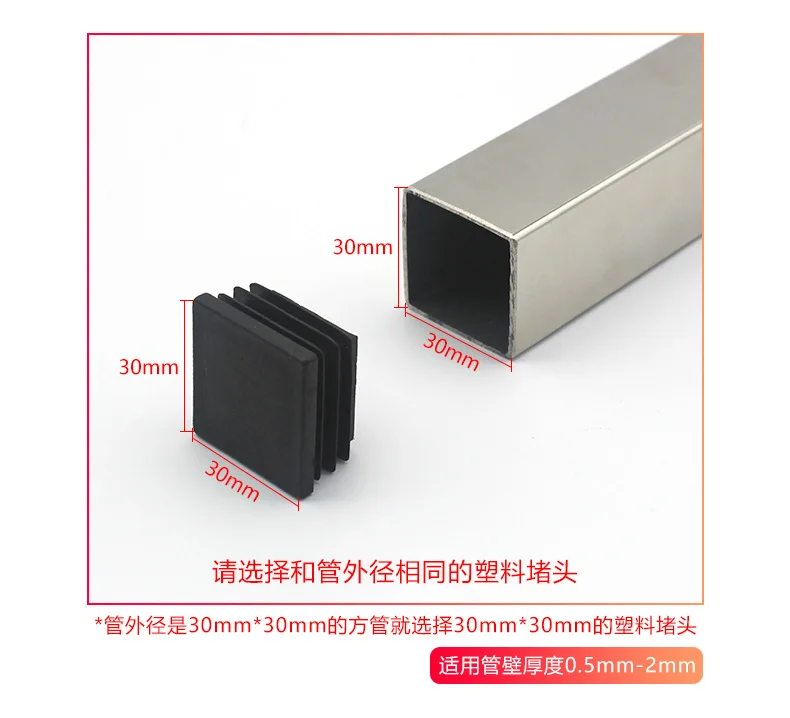

SQM Series heavy wall polyethylene plugs for square metric tubing are designed to fit multiple tube gauges and provide a secure fit. Poly tube plugs are ideal for office and patio furniture, tubular racks, appliances, exercise equipment, or anywhere a finished look is needed.

Stocks Plugs for Square Metric Tubes in many sizes for immediate shipment.

OEM and ODM Services

OEM and ODM Services1 Screen or silk print: better for 1-2 colors design

2 Paper label/sticker: colorful based background,

better for more than 3 colors design

3 Plastic label/sticker: clear or white based background, better for 1-3 colors design

4 Paper box or your own packaging could also be changed according to your design

5 New moulds, new style or shape welcome

Product Description

High Lights

Molding plastic caps has the most extensive line of PVC HDPE PP etc. caps, plugs, flange covers, and masking products available. Of course, this broad line of products evolved due to the special advantages that caps and plugs have over most hard plastic closures.

Here are some of the most common reasons people choose to use soft plastics when specifying everything from dust caps to plastic closures. When used as the material for a cap or plug, it provides a much better seal and will not crack or shred like hard plastic closures.

Available for almost any application and vehicle including marine, automotive, commercial and power sports. Keep your battery terminal and post protected as well as starter and alternator connectors.

Highlights of Our Mold & Parts Making

Plastic materials:

PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PBT+GF30%...etc.

Other materials:

Rubber, Silicone rubber, LSR, Aluminum, Zinc Alloy...Metal...etc.

Quality:

ROHS and SGS standard

Feature:

Non marking and Non flash

Size:

According to your drawing

Color, Quantity, Unit price, Tooling cost, Tooling size:

To be discussed

Mold structure:

Injection Mould, Plastic Mold, Overmould, 2k mould, Die Casting Mould, Thermoset Mold, Stack Mold, Interchangeable Mold, Collapsible Core Mold, Die Sets, Compression Mold, Cold runner system LSR Mold,...etc.

Mould Base:

HASCO standard, European standard, World standard

Mould Base Material:

LKM, FUTA, HASCO, DME, INVENTIVE etc. or as per customer's requirement.

Surface Finish:

Texture (MT standard), high gloss polishing

Finish:

Mirror finish etc.

Cavity / Core steel:

P20, 2311, H13, 2344, Starvax 420, 236, AdC3, S136, 2312, 2379, 2316, 2083, Nak80, 2767 etc.

Cavity:

Single cavity, Muti Cavity, based on customer's requirement.

Hot / Cold Runner:

HUSKY, INCOE, YUDO, INVENTIVE, HASCO, DME, MoldMaster, Masterflow, Mastip, Taiwan made brand...etc.

Mould Life:

1,000 to 1,000,000 shots

(according to your working environment)

Design & Program Softwares:

CAD, CAM, CAE, Pro-E, Solid works...etc.

Equipments:

High speed CNC, standard CNC, EDM, Wire Cutting, Grinder, Plastic Injection Molding Machine for testing and production from 50-3000T available, all 35 sets.

Package:

Standard exported wooden box packed, fumigation process (upon required)

Mold building lead time:

T1, 20~50 days, parts measurement report (upon required).

Annual production:

Around 300 sets of mold, and 10 Million parts for production.

In short, We can provide you both products and molds in best quality. All of our products and molds are 100% designed and made here in China. We are confident to satisfy our customers with best value of moldmaking workmanship. With more than 25 years of experience and being the performance level in Dongguan of China, we have kept many key customers giving us repeated orders from overseas.

We attended EUROMOLD exhibitions every year to meet our customers !

Detailed Images

Похожие товары

JuBo, жесткая маленькая тонкая Настенная ПВХ электрическая труба, 10 мм пластиковая труба, Малайзия для украшения

Horrific Demon Adult Scary Props Devil Flame Zombie Mask Evil Clown Latex Halloween Masks Horror Grimace

Прямоугольный Телескопический алюминиевый трубчатый 100x50x5 мм от завода ZHONGLIAN

Высококачественная ПВХ пластиковая квадратная труба ПВХ труба квадратные трубы

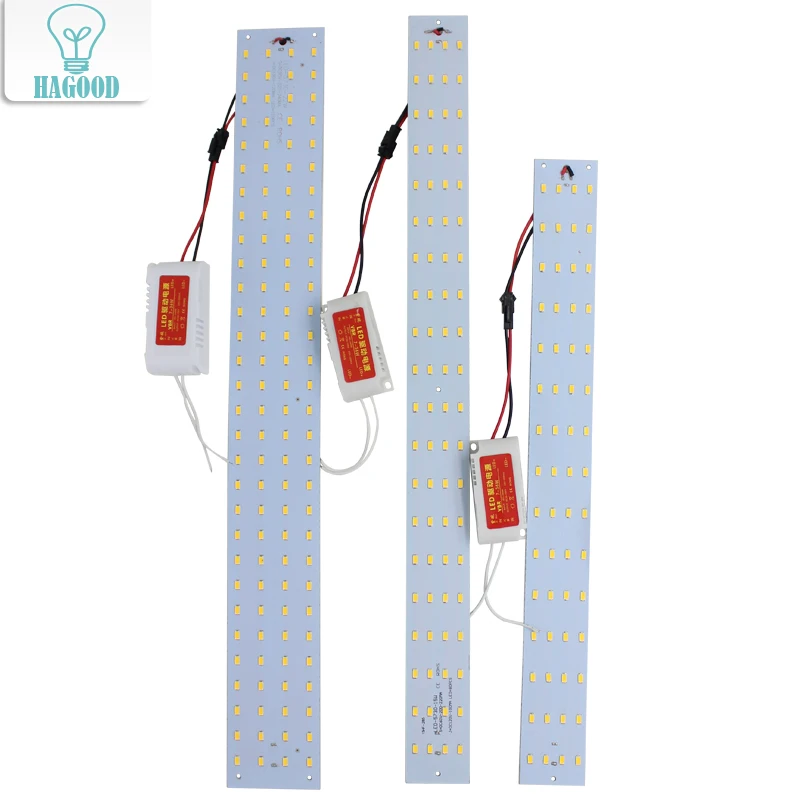

180-265 в магнитные 10 Вт 15 Вт 21 Вт прямоугольные квадратные светодиодные потолочные лампы, Сменные лампы-трубки

MC-275AC пневматический китайская фабрика прямоугольные трубы квадратного сечения круглые полу автоматическая труборезная машина

Складной антипригарное покрытие барбекю гриль кастрюля с отверстиями сковородка обжиг прямоугольник Топпер деревянной ручкой круглая

Новые поступления

Новинки товаров от производителей по оптовым ценам