Высокой плотности цвет целлюлозы фиброцементная плита

- Категория: >>>

- Поставщик: Hangzhou Bossyin Construction Material Co. Ltd.Hangzhou Ltd.

Сохранить в закладки 1600446344244:

Описание и отзывы

Характеристики

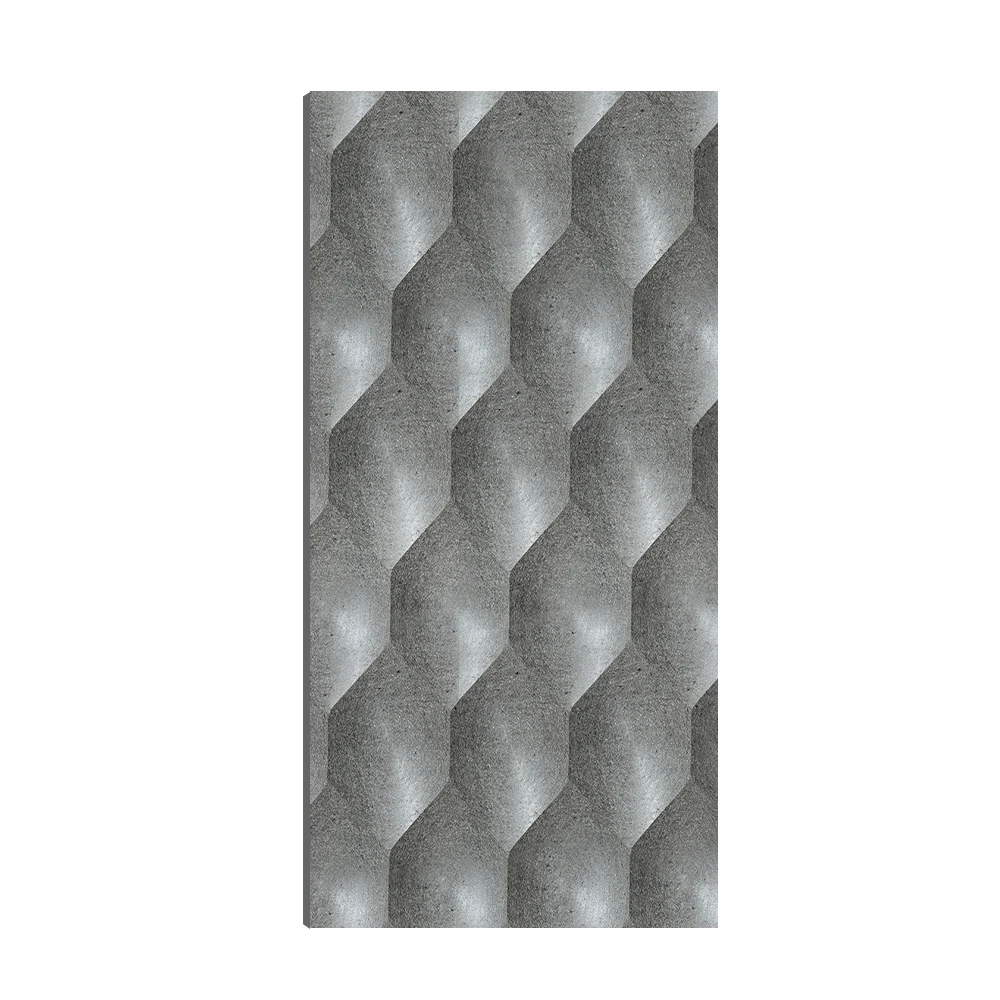

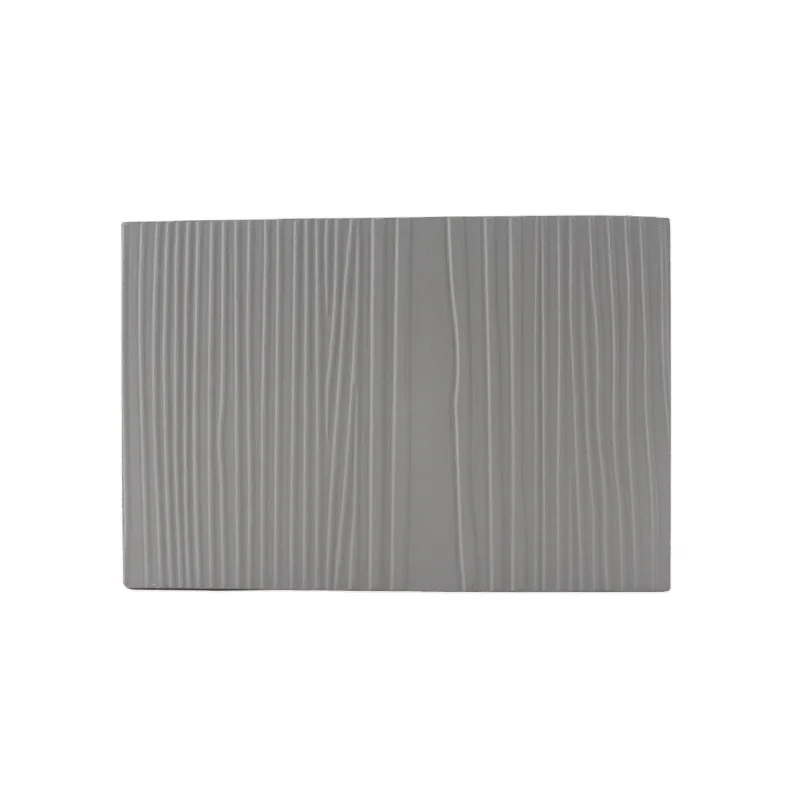

Composite Exterior Wood Grain Wall Siding Fiber Cement Board

Basic Information of Fiber Cement Board

| Descriptions: | Composite Exterior Wood Grain Wall Siding Fiber Cement Board |

| Raw materials: | Cement + Fiber + Sand |

| Code: | BS-FCB-PWG |

| Width: | 200mm, 210mm |

| Thickness: | 7.5mm, 6mm-12mm available |

| Length: | 3000mm, 3050mm, 3660mm |

| Packaging: | Pallet Packing |

| Thickness: | 0.9mm, 1.0mm, 1.1mm, 1.2mm, 1.3mm |

| Green Material: | 100% Non-Asbestos |

| Sample Lead time: | As usual 3-7 working days |

| Production Time: | 7-15 days for available designs,Customized: 20~40 days |

| Where Can Use: | Bathroom, kitchen, dinning room, living room, shop, commercial buildings,Hospital, school, bar, hotel, restaurant... for exterior wall decoration. |

| Features: | 1 Environment friendly and Fire proof |

| 2 Anticorrosive, Resistant to insect and termite | |

| 3 Light weight & high strength and Small deformation coefficient | |

| 4 Easy installation and maintenance and cleaning |

Product Data

| Item | Index |

| Density | ≥1.25 g/cm3 |

| Thermal Conductivity | ≤0.30 W/(m·k) |

| Water Absorption | ≤ 38% |

| Water Contain | ≤ 10% |

| Moisture Movement | ≤0.25% |

| Freezing | No cracking or delaminating after 25 times of freeze-thaw cycles |

| Non-water soaking | No Water Forms after being tested for 24 hours |

| Dry Shrinkage | ≤ 0.50% |

| Bending Strength | ≥14 Mpa |

| Impact resistance (Oven Dry) | No Continuous Cracking After An Impact |

Technical Parameter

| Impermeability | After 24-hour inspection, no water droplets were found. | |||

| Hot Rain Test | Fifty hot rain cycles, no cracks and delamination on the plate surface | |||

| Hot Water Test | The ratio of saturated flexural strength to saturated flexural strength is greater than or equal to 70% after 56 days immersion at 60 degrees Celsius. | |||

| Immersion drying test | After 50 cycles of drying, the saturated flexural strength ratio is greater than or equal to 70%. | |||

| Mildew Resistance Test | Antifungal property grade 0 | |||

| Water Resistance | After 30 days, no cracking, no layering, no falling off, no swelling and no color change were observed. | |||

| Acid Resistance | After 15 days, no cracking, no layering, no falling off, no swelling and no color change were observed. | |||

| Alkali Resistance | After 15 days, no cracking, no layering, no falling off, no swelling and no color change were observed. | |||

| Toxicity of tobacco production | Complying with GB/T20285-2006 standard, safety level (AQ level) | |||

| Non-asbestos test | It conforms to HJ/T223-2005 standard and does not contain asbestos. | |||

| Radioactivity | Complying with GB6566-2010 standard and meeting the requirements of Class A decorative materials | |||

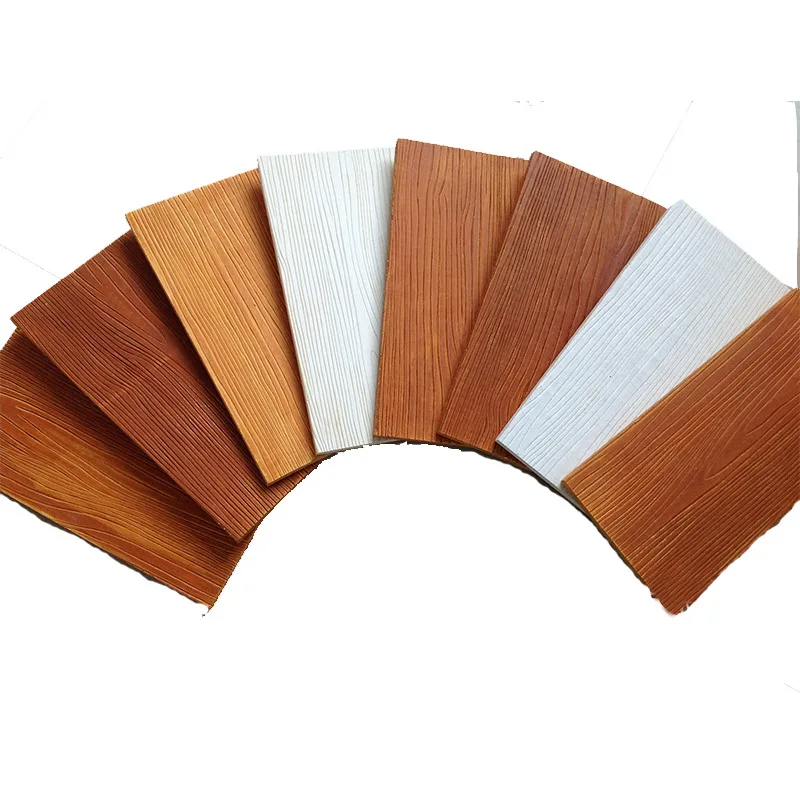

Color we can do

Fiber Cement Siding Board Main Features

1. Environment friendly

Fiber Cement Siding Board is the 100% non -asbestos product. During using, our board will not produce any toxic gas and radiation.

2. Fire proof

Fiber Cement Siding Board is fire resistance material. When fire happens ,not only the place occurs the fire, but also the place fire spreads to will be damaged and will bring loss, therefore, the fire resistance of outer wall is very important. Calcium silicate board is with excellent fire resistance character. In addition, it will be not causing crack and stratification after fire.

3. Anticorrosive

Fiber Cement Siding Board is without any growth condition for fungus, and it will not be mildew in any circumstance.

4. Resistant to insect and termite

Under 11pa steam curing, the Fiber Cement Siding Board is hardening. Its own structural property decides that the insect and termite can’t survive in the board.

5. Light weight & high strength

The wall, hang ceiling or other structural parts, which is made of board and profile, when using the Fiber Cement siding board, it will be with superiority of light weight and high strength.

6. Easy working

the installation of board is dry construction, which is fast. It is can be installed with ordinary wood working tool.The board is easy to be processed.

7. Easy decoration

various decorative processing can be made for the board surface, such as coating materials or all kinds of adhesive.

8. Small deformation coefficient

The materials of Fiber Cement Siding Board are cement, quartz-flour, natural xylem fiber and other minerals. Under high temperature autoclave, the calcium from the cement and the silicate from the quartz flour will react to form a new crystal tobermorite. It will harden within 24 hours after molding, therefore the shape of board is steady and deformation coefficient is small.

Fiber Cement Siding Board Installation

Fiber Cement Siding Board Application

Bossyin Factory

Our main products are plastic extrusion & plastic film-coated & plastic co-extrusion exterior wall siding, plastic extrusion & coextrusion profile, PVC foam profile and other building materials.BASF, ASA, the addition of calcium and zinc stabilizers makes our goods with very good weather fastness,discoloration prevention, waterproof, insect proof, good bearing capacity, 100% environmental protection, etc., various colors, no need to paint and easy to process and a wide range of applications.The use time can be 50 years !

Bossyin focuses on the quality and have developed 10 patented products, such as embossed PVC siding, PVC stairs handrail, PVC accessories and other construction materials.There are more products under development, please continue to pay attention to us.

New and stable products is our aim.We are Top 3 plastic extrusion and coextrusion craft manufacturer in China!

Just show us your drawing or real plastic extrusion and co-extrusion process sample,we can develop it for you! Let’s make a new comfortable and better living together.

Q1: Wonder if you accept small orders?

A1: Do not worry. Feel free to contact us .in order to get more orders and give our clients more convener ,we accept small order.

Q2: Can you send products to my country?

A2: Sure, we can. If you do not have your own ship forwarder, we can help you.

Q3: Can you do OEM for me?

A3: We accept all OEM orders,just contact us and give me your design.we will offer you a reasonable price and make samples for you ASAP.

Q4: What's your payment terms ?

A4: By T/T,LC AT SIGHT,30% deposit in advance, balance 70% before shipment.

Q5: How long is your production lead time?

A5:It depends on product and order qty. Normally, it takes us 15 days for an order with MOQ qty.

Q6: When can I get the quotation ?

A6: We usually quote you within 24 hours after we get your inquiry. If you are very urgent to get the quotation.Please call us or tell us in your mail, so that we could regard your inquiry priority.

Похожие товары

OEM 100% неасбестовая 18 мм волокнистая цементная плита 1200*2400 Размер наружная настенная декоративная ДВП с заводом

Оптовая продажа производитель цементных плит из древесного волокна высокой плотности

Деревянная отделка волокнистые цементные доски для внешней облицовки стеновая панель из цементной плиты

Китайский профессиональный производитель 20 мм 30 фиброцементные фасадные панели специализированные для внутреннего применения

100% асбест бесплатно CE утвержден средней плотности канавок волокна цемента доска

100% неасбестовая цементная фасадная доска наружные декоративные стеновые панели

Хорошая термостойкая цементная огнестойкая плита доска стеновые панели

Новые поступления

Новинки товаров от производителей по оптовым ценам